Heat-shrinkable corner protector

A corner protection and heat shrinking technology, applied in the field of packaging, can solve the problems of decreased tear resistance, no anti-counterfeiting or anti-unpacking function, poor fixing firmness, etc., and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

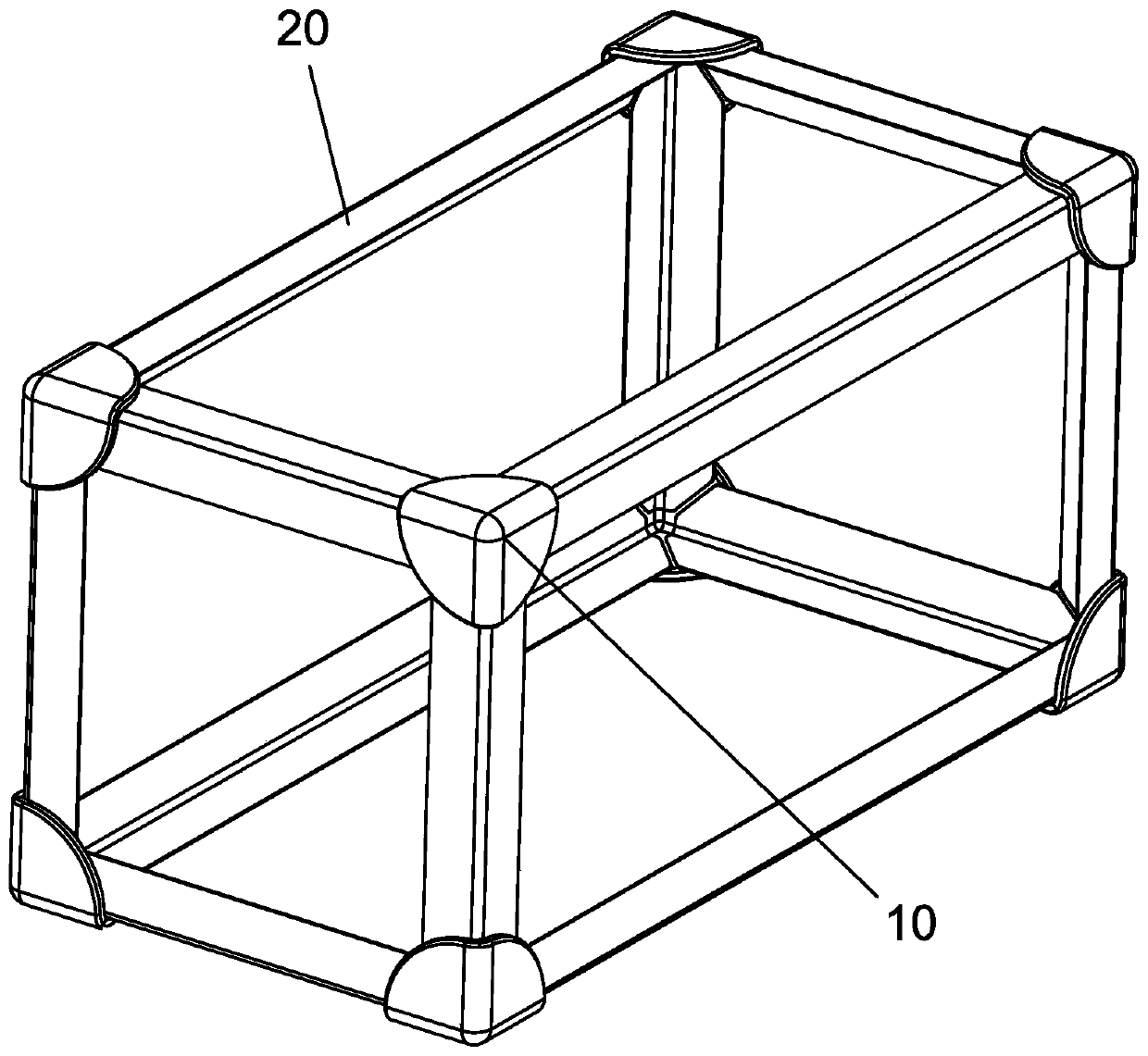

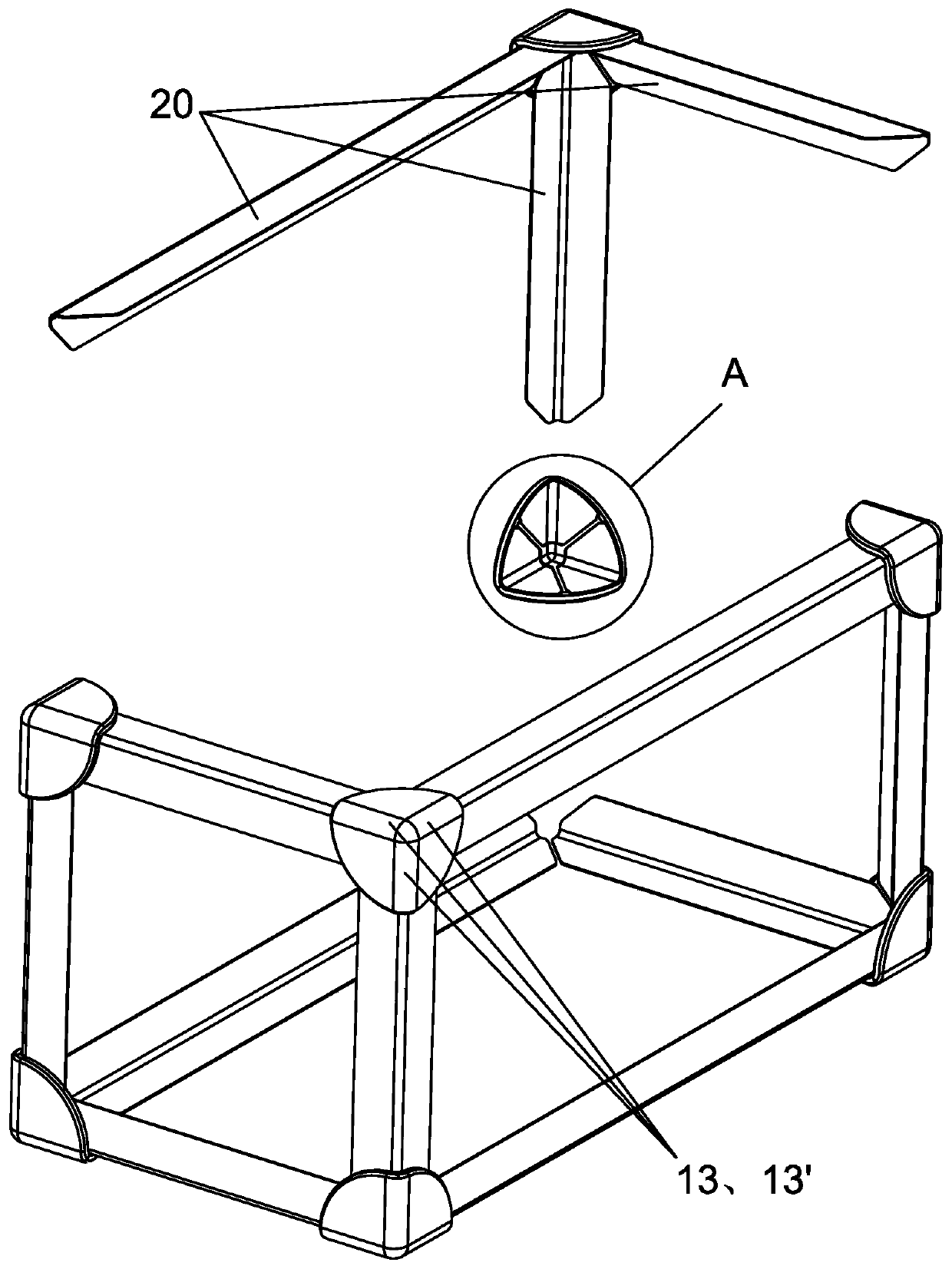

[0032] refer to Figure 1 to Figure 4 ,Such as Figure 1 to Figure 4 The shown heat-shrinkable corner protector includes corner protectors 10, which are arranged at the 8 top corners of the box (not shown in the figure) during packaging, and each corner protector 10 is composed of three support plates 11, and the three support plates 11 of each corner protector 10 are all in contact with the three surfaces at the top corners of the box body, and the corner protectors between the adjacent top corners of the box body during packaging The body 10 is connected by a heat-shrinkable film 20, and the end of the heat-shrinkable film 20 is bonded to the joint of the two support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com