A briquetting automatic production line

An automatic production line and briquetting machine technology, which is applied to presses, mechanical conveyors, storage devices, etc., can solve the problem of low production capacity of waste briquettes, facilitate large-scale production, improve identification accuracy, and reduce failure rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

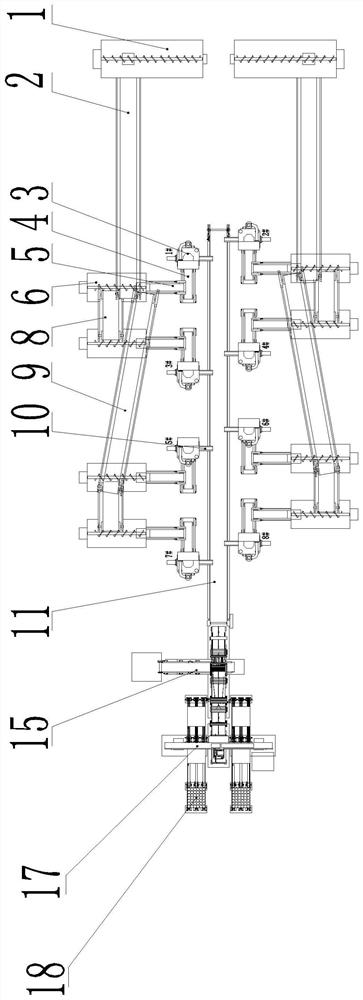

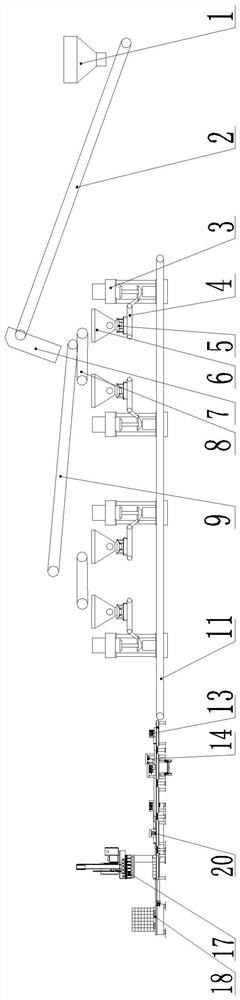

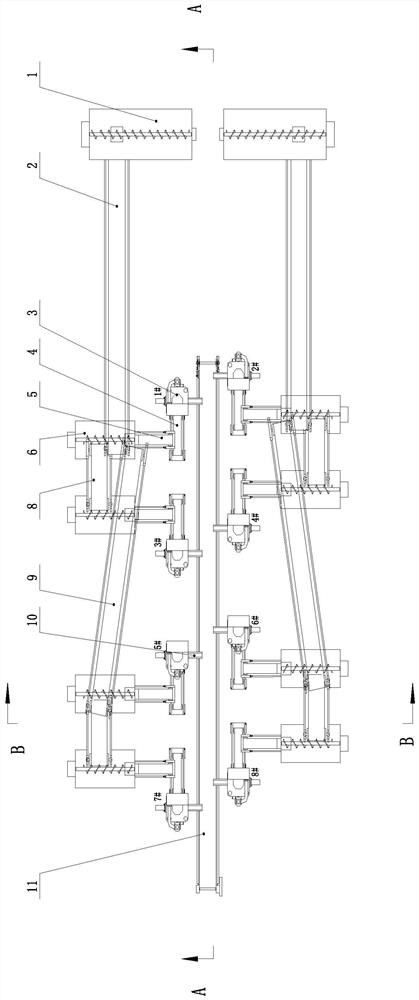

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0053] according to Figure 1 to Figure 7 In the shown automatic briquetting production line, according to the direction of material transportation, the waste conveying mechanism for moving waste, the three-way distribution hopper 7 (which is hidden in the top view for the convenience of overall display), and at least two sets for The feeding mechanism group, the briquetting machine 3, and the shared discharge conveyor belt 11 of the briquetting machine for collecting and distributing materials;

[0054] The waste conveying mechanism outputs the waste to the inlet of the distribution hopper 7, and the distribution outlet of the distribution hopper 7 is at least two, and each distribution outlet is discharged to a different feed mechanism group; each set of the feed The mechanism group includes two distributing screw feeders 6 and a horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com