A dust suppression sprayer

A sprayer and dust reduction technology, which is applied in spraying devices, liquid spraying devices, separation methods, etc., can solve the problems of poor dust reduction effect, achieve the effect of convenient maintenance and repair, convenient adjustment and fixing, and perfect dust reduction function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

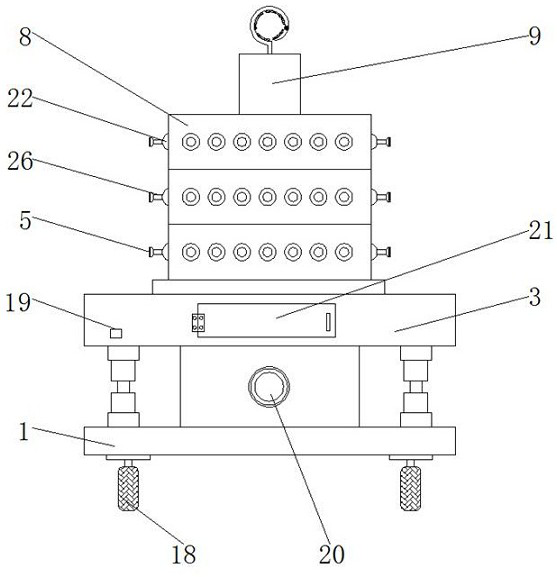

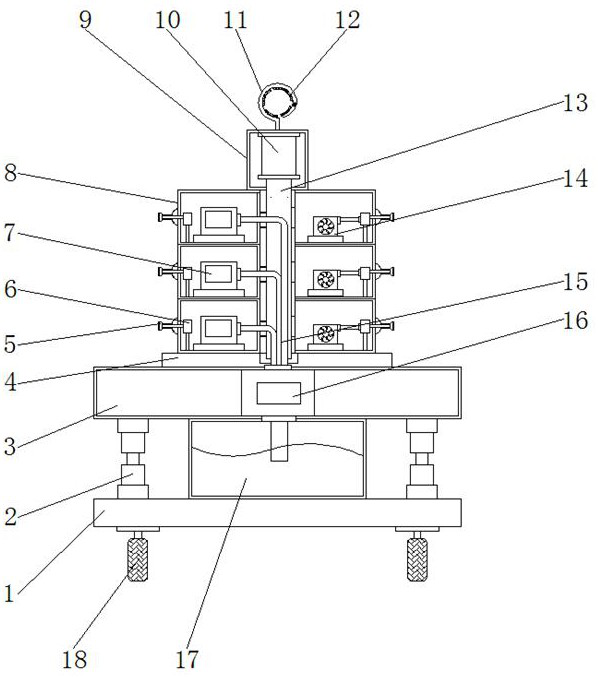

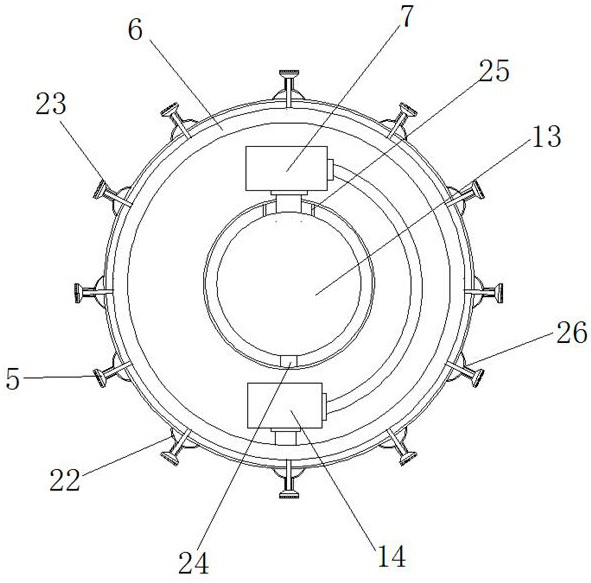

[0021] The present invention will be further elaborated below by means of the accompanying drawings and examples.

[0022] Embodiments of the present invention provide a dust suppression sprayer, such as Figure 1-3 As shown, including the base 1, both sides of the bottom of the base 1 are fixedly connected with universal wheels 18, through the universal wheels 18 provided, it is convenient for people to carry and move the equipment, and the top of the base 1 is fixed in sequence from left to right The telescopic seat 2 and the water tank 17 are connected, and the position of the dust removal box 8 can be raised or lowered by the telescopic seat 2 provided, which is convenient for people to adjust and fix the device, and improves the dust suppression function of the device. The front of the water tank 17 is provided with an inlet The nozzle 20 and the top of the telescopic seat 2 are fixedly connected with a fixed seat 3, and the front of the fixed seat 3 is respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com