Rotating machinery frequency-doubled fault diagnosis method based on three-dimensional holographic difference spectrum

A technology of three-dimensional holography and rotating machinery, which is applied in the testing of machines/structural components, complex mathematical operations, measuring devices, etc., and can solve problems such as limited applications and inability to diagnose root causes of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

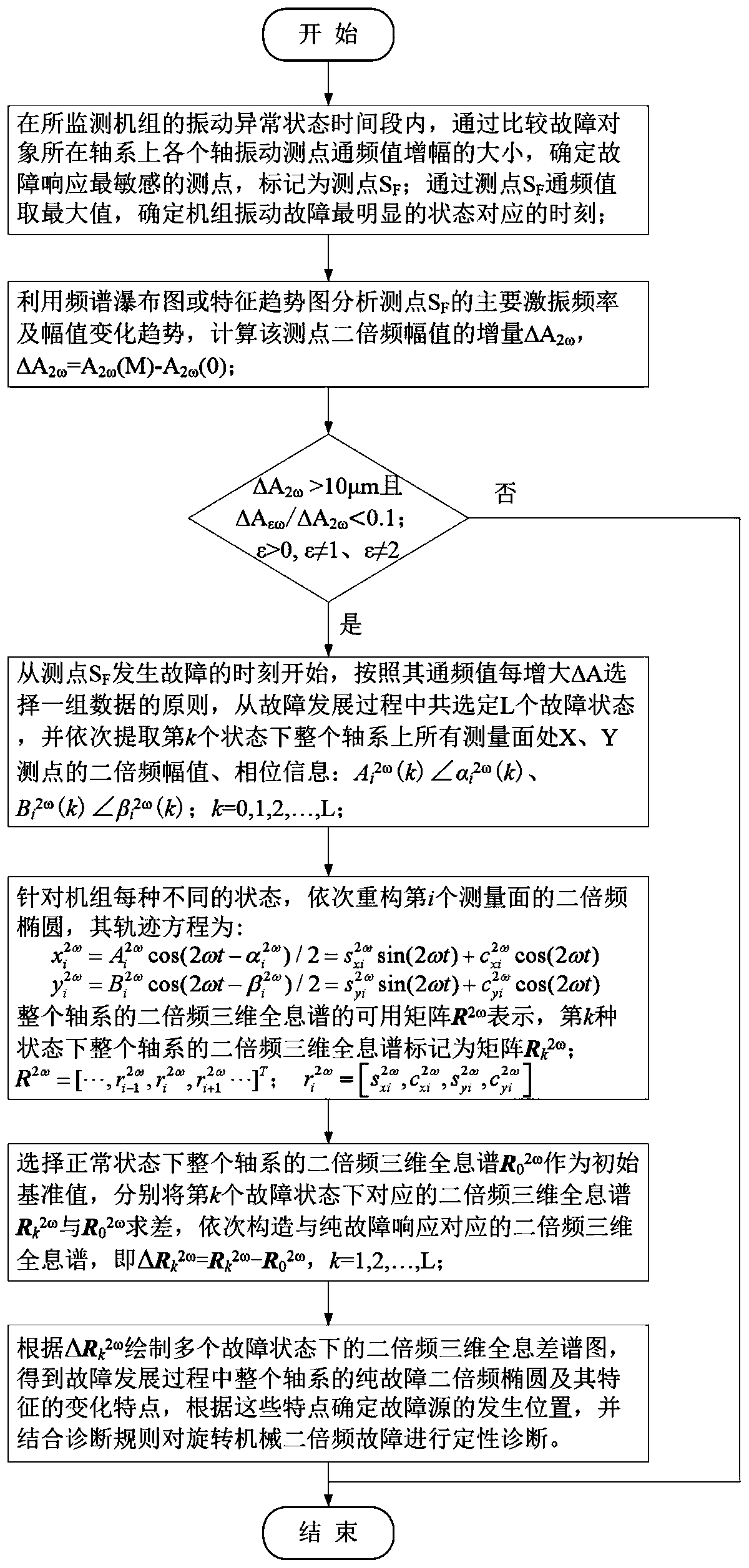

Method used

Image

Examples

Embodiment 1

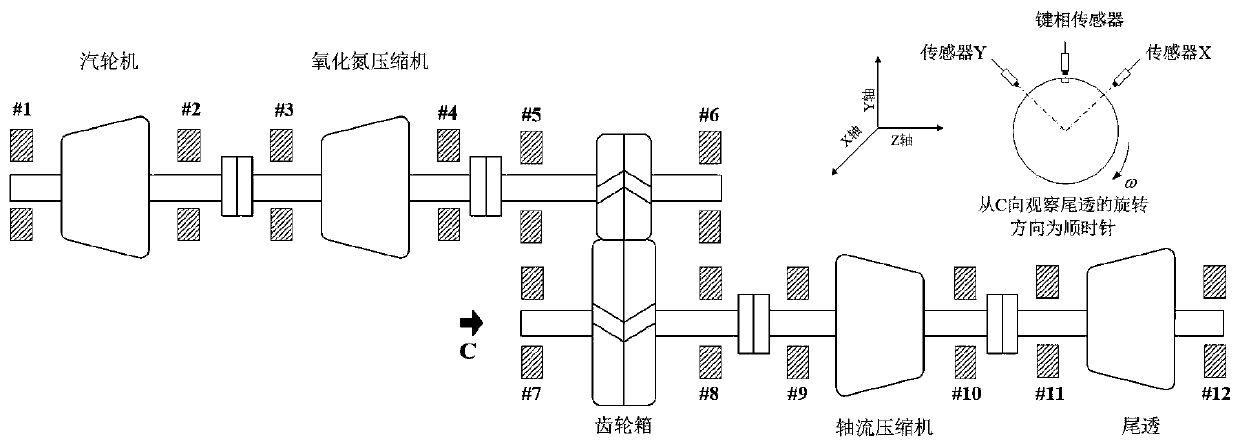

[0034] Embodiment 1, using the method of the present invention to carry out fault analysis and diagnosis to a nitric acid four-in-one unit, this unit is a large-scale key power equipment of a nitric acid enterprise, its layout and sensor positions are as follows figure 2As shown, it is composed of five parts: steam turbine, nitrogen oxide compressor, gear box, axial flow compressor, and tail gas. Among them, the tail gas is used to recover the pressure energy and heat energy of the tail gas discharged from the absorption tower, and convert these energies into Mechanical energy is used to drive the axial flow compressor and nitrogen oxide compressor to work, and at the same time adjust the pressure of the whole device. Due to the complex composition of the working medium of the tail penetrator and often containing corrosive gases, the intake temperature is generally as high as 400-500 degrees, so it is prone to failure during operation. The unit contains a total of 12 sliding ...

Embodiment 2

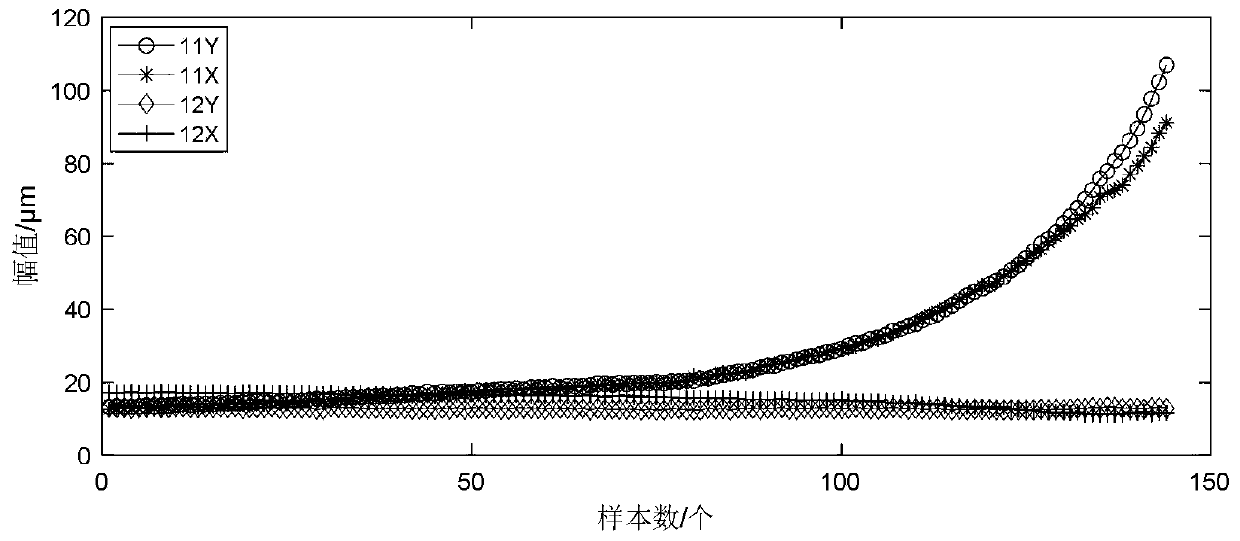

[0050] Embodiment 2, using the method of the present invention to analyze and diagnose the fault of a certain blast furnace blower unit. The blower unit consists of five parts: motor, gearbox, axial flow compressor, variable speed clutch, and gas turbine (TRT for short). The measuring points are arranged as Image 6 shown. Among them, the rated operating speed of TRT is 3000rpm (50Hz), and its rotation direction is clockwise when viewed from C direction. Except for 1#, 2#, 4#, 5#, 10#, and 11# bearings, two eddy current sensors perpendicular to each other (45 degrees, 135 degrees) are installed near the other bearings, and each shafting is equipped with A key phase sensor. Through the remote online data acquisition system supporting the unit, the operating status of the unit can be monitored remotely online in real time. During a normal start-up process, the unit began to load normally after the speed was increased to the working speed, and the TRT vibration was abnormal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com