A flexible and stretchable transparent copper clad laminate and its preparation method

A copper-clad laminate and transparent technology, which is applied in the field of transparent copper-clad laminate and its preparation, can solve the problems of limited application fields and lack of stretchability, and achieve good flexibility and stretchability, good application market and development prospects, and convenient peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

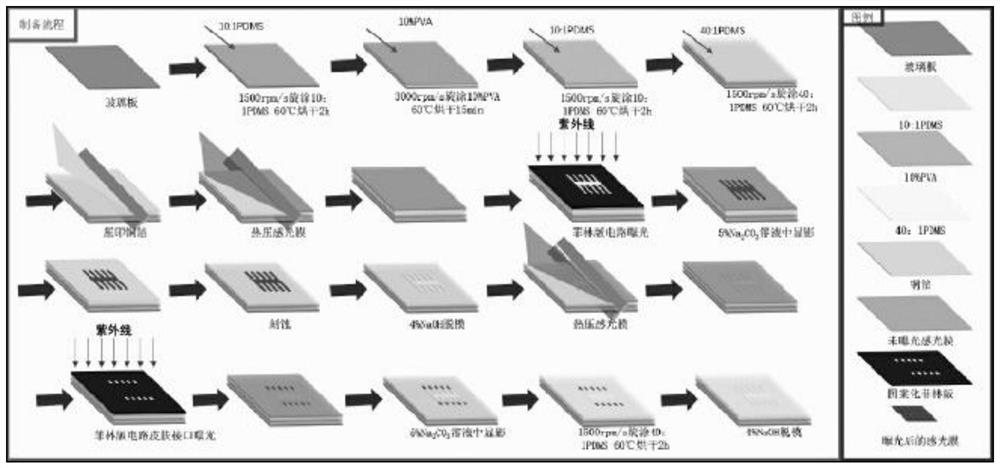

[0059] A flexible and stretchable transparent copper-clad laminate sequentially includes a supporting substrate, a separation layer, a peeling layer, a base layer, an adhesive layer, a patterned metal layer and a patterned insulating layer. When in use, the release layer, base layer, adhesive layer, patterned metal layer, and patterned insulating layer are peeled off using the separation layer as a transition, and the patterned insulating layer is attached to the skin surface during use.

[0060] Such as figure 1 Shown, the preparation method of this transparent copper-clad laminate comprises the following steps:

[0061] S0, choose a hard sheet as the supporting substrate, and the supporting substrate can be used to provide a certain rigidity and hardness, which can be a glass sheet, a metal sheet or a plastic sheet, etc., and glass sheet is preferred in this embodiment;

[0062] S1, preparation of the separation layer: Spin-coat 10:1 PDMS on the support substrate (the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com