Communication construction cable burying device

A cable and electric telescopic technology, applied in the direction of cable laying equipment, etc., can solve the problems of potential safety hazards in cables, and achieve the effects of reasonable buried depth, enhanced adaptability, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention.

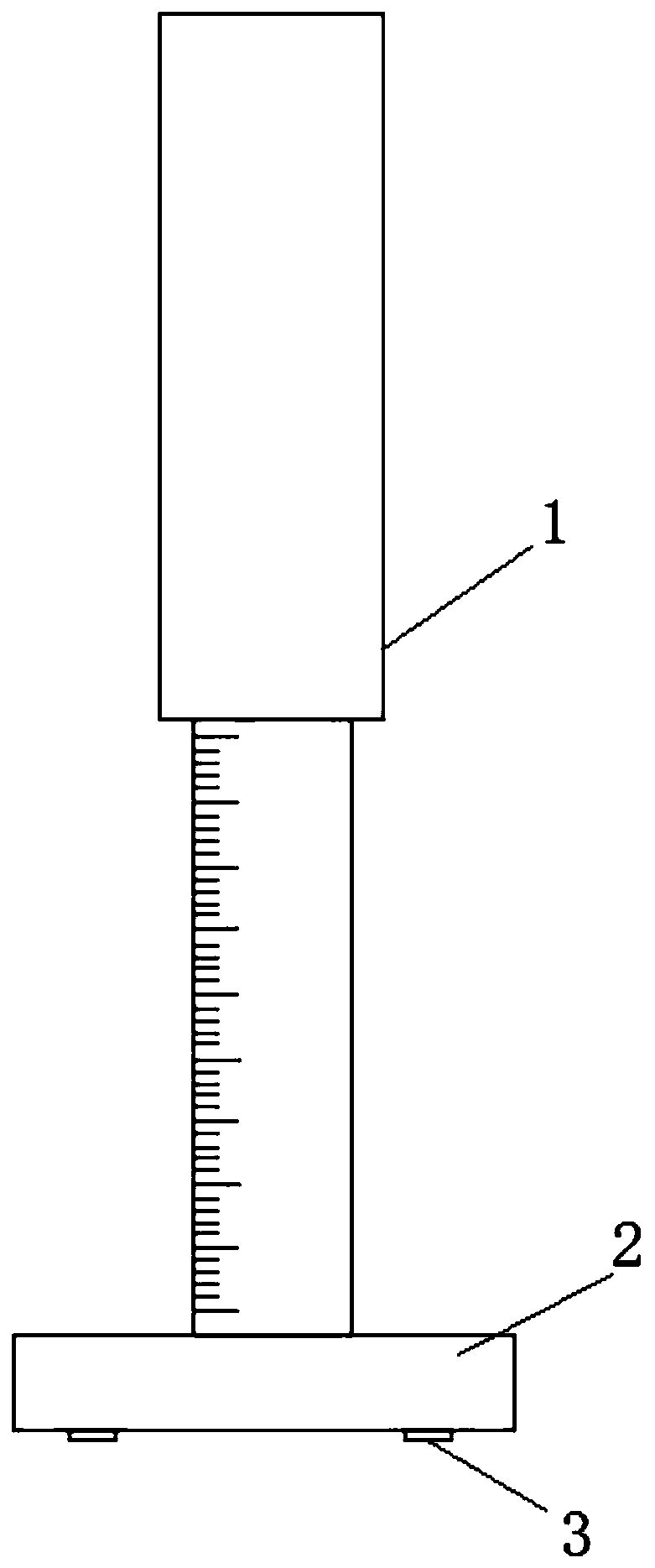

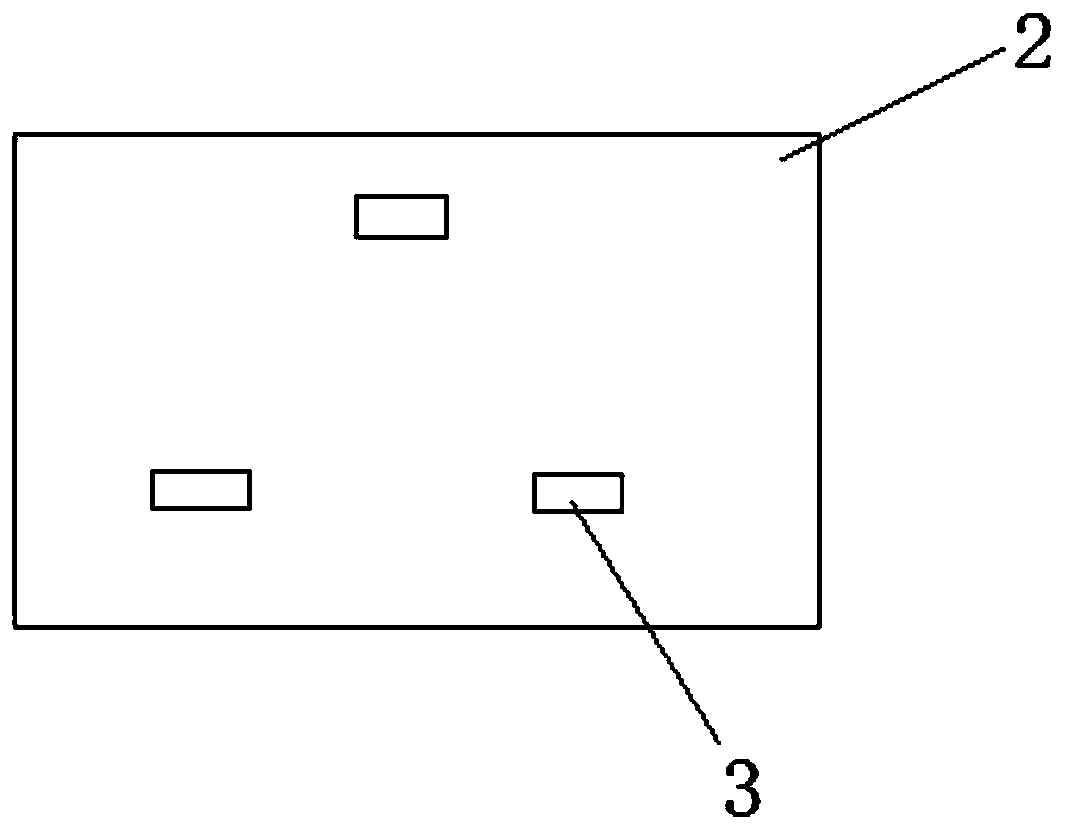

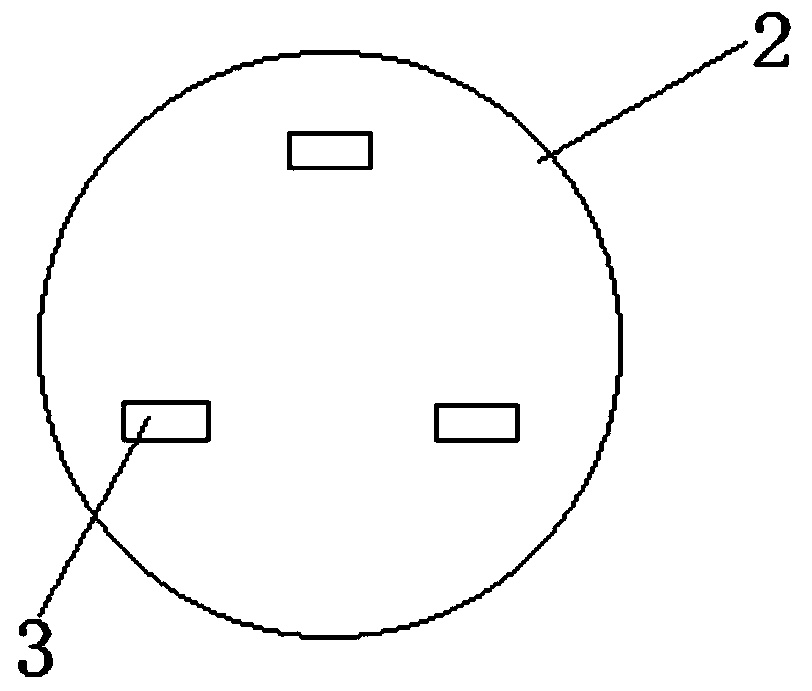

[0030] see figure 1 As shown, the present invention provides a communication construction cable burying device, the burying device is provided with an electric telescopic probe rod, and the electric telescopic probe rod comprises a telescopic rod 1 and a probe 2 detachably connected to the telescopic rod 1, so The lower surface of the probe 2 is provided with an ultrasonic ranging sensor 3, the telescopic power source of the electric telescopic probe rod is a servo motor, the projection of the probe 2 and the telescopic rod 1 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com