Uniformly dispersed ultra-small metal nanoparticle material and dispersion method thereof

A technology of uniform dispersion of metal nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of electrode material electrochemical performance degradation, secondary agglomeration of nanoparticles, and high cost. Achieve the effect of facilitating ion transfer and electrolyte diffusion, preventing agglomeration, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

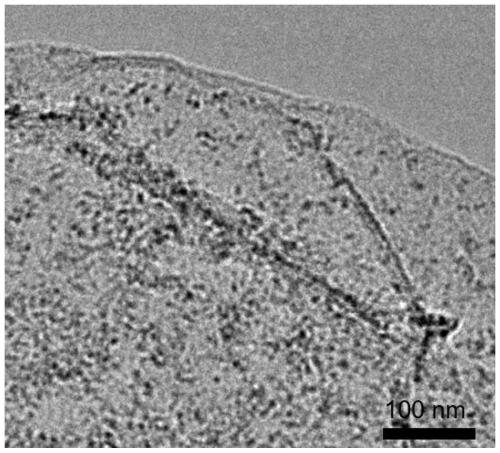

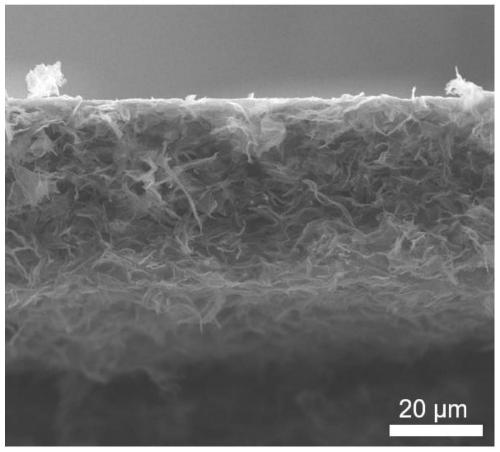

Image

Examples

Embodiment 1

[0026] A method for uniformly dispersed ultra-small metal nanoparticles, comprising the following steps:

[0027] (1) Graphene oxide (GO) aqueous dispersion (1 mg / ml) was prepared by a modified Hummers method. Specific steps are as follows:

[0028] (1-1) A 250ml large beaker, put ice cubes in it, and provide an ice water bath;

[0029] (1-2) Measure 30ml of H in a test tube 2 SO 4 , then weigh 1g of graphite, 0.5g of sodium nitrate, and 3g of potassium permanganate with an electronic balance;

[0030] (1-3) Put the magnet into the Erlenmeyer flask, then gently pour the concentrated sulfuric acid into the Erlenmeyer flask, and then put it into the electromagnetic stirrer;

[0031] (1-4) Mix graphite and sodium nitrate into the conical flask, stir and react for three minutes, then add potassium permanganate to the conical flask, control the temperature below 20°C, stir and react for 2 hours; heat up to 35°C, continue Stir for 30 minutes;

[0032] (1-5) Mix water and disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com