A microsphere chain for detecting ascorbic acid and its preparation method and application

A technology of ascorbic acid and carbon microsphere chains, applied in chemical instruments and methods, analyzing materials through chemical reactions, and analyzing materials through observing the impact on chemical indicators, etc., can solve the problem of unsatisfactory detection results, To solve problems such as complex detection, achieve excellent sensing performance, low preparation cost, and improved detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

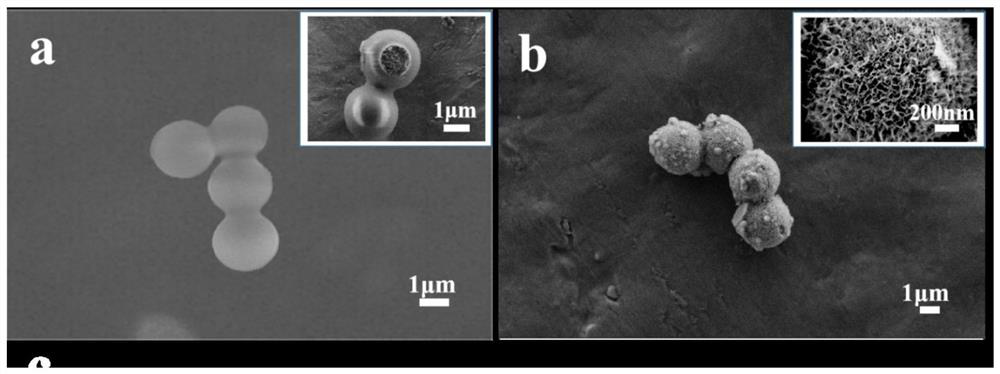

[0030] The specific preparation process of the present invention is as follows: 1. get 10 g of sucrose and dissolve it in 80 ml of deionized water, and transfer it to an autoclave. Then the autoclave was put into a drying oven and heated to 190 ° C for 2 hours. After the reaction was completed, it was naturally cooled to room temperature, and the product was washed several times with deionized water and ethanol, then dried in a drying oven, and heated to 80 ° C for 12 hours. When the drying oven is lowered to room temperature, the carbon microsphere chains are obtained.

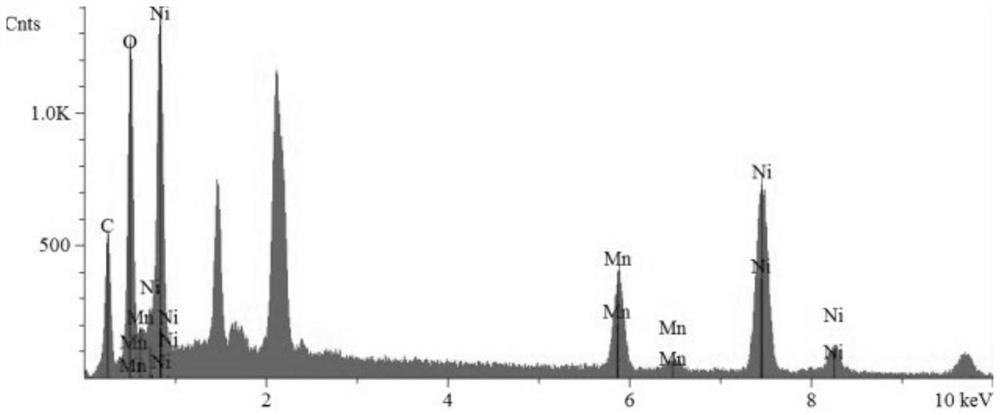

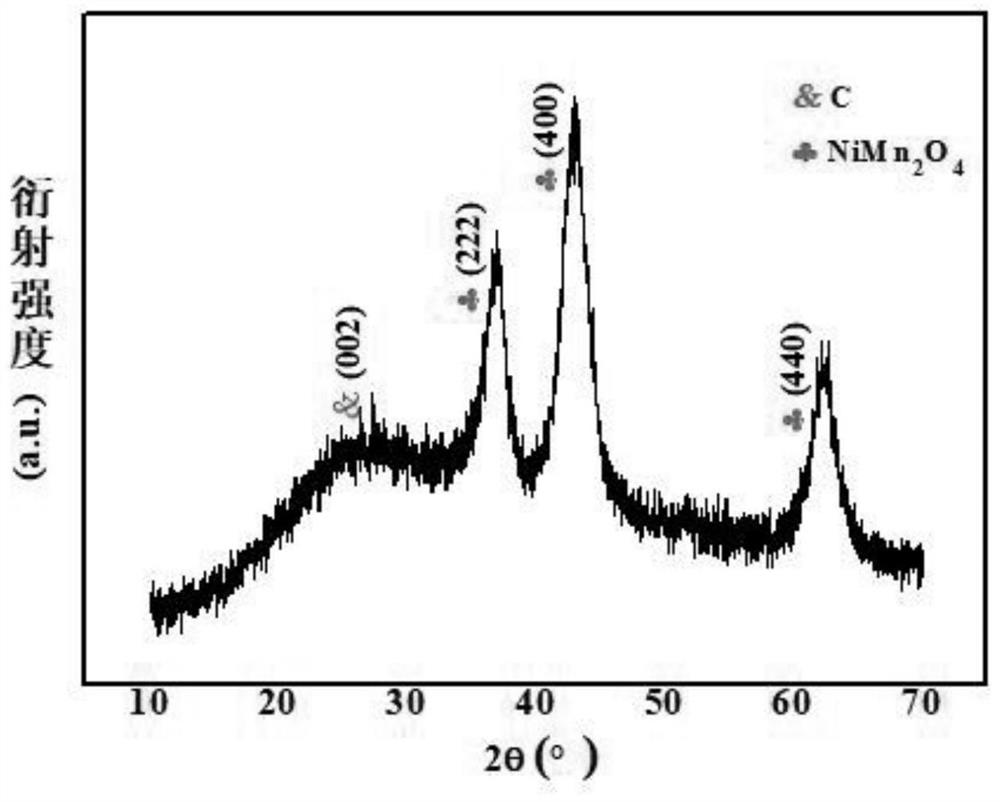

[0031] ②Using the oil bath method, add 20 mg of the above-prepared carbon microsphere chains into 40 ml of deionized water, and sonicate for 30 minutes. 75 mg Ni(NO 3 ) 2 ·6H 2 O, 132.7 mg Mn(NO 3 ) 2 4H 2 O, 35 mg HMT and 7.2 mg TSC were dissolved in the above suspension and sonicated again for 15 minutes. Then it was put into an oil bath and continued magnetic stirring, heated to 90 ° C for 6 hours. ...

Embodiment 2

[0036] ① Dissolve 20 g of sucrose in 80 ml of deionized water and transfer it to an autoclave. Then the autoclave was put into a drying oven and heated to 190 ° C for 2 hours. After the reaction was completed, it was naturally cooled to room temperature, and the product was washed several times with deionized water and ethanol, then dried in a drying oven, and heated to 80 ° C for 12 hours. When the drying oven is lowered to room temperature, the carbon microsphere chains are obtained.

[0037] ②Using the oil bath method, add 20 mg of the above-prepared carbon microsphere chains into 40 ml of deionized water, and sonicate for 30 minutes. 75 mg Ni(NO 3 ) 2 ·6H 2 O, 132.7 mg Mn(NO 3 ) 2 4H 2 O, 35 mg HMT and 7.2 mg TSC were dissolved in the above suspension and sonicated for 15 minutes. Then it was put into an oil bath and kept stirring, heated to 90 ° C for 6 hours. After the reaction was completed, it was allowed to cool naturally to room temperature. The obtained bl...

Embodiment 3

[0039] ① Dissolve 10 g of sucrose in 80 ml of deionized water and transfer it to an autoclave. Then the autoclave was put into a drying oven and heated to 190 ° C for 2 hours. After the reaction was finished, it was naturally cooled to room temperature, and the product was washed several times with deionized water and ethanol, then put into a drying oven for drying, and heated to 80°C for 8 hours. When the drying oven is lowered to room temperature, the carbon microsphere chains are obtained.

[0040] ② Using the oil bath method, add 40 mg of the above-prepared carbon microsphere chains into 40 ml of deionized water, and sonicate for 30 minutes. 75 mg Ni(NO 3 ) 2 ·6H 2 O, 132.7 mg Mn(NO 3 ) 2 4H 2 O, 35 mg HMT and 7.2 mg TSC were dissolved in the above suspension and sonicated for 15 minutes. Then it was put into an oil bath and kept stirring, heated to 90 ° C for 6 hours. After the reaction was completed, it was allowed to cool naturally to room temperature. The obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com