Steel cable strength testing device for coal equipment

A strength test, steel cable technology, applied in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

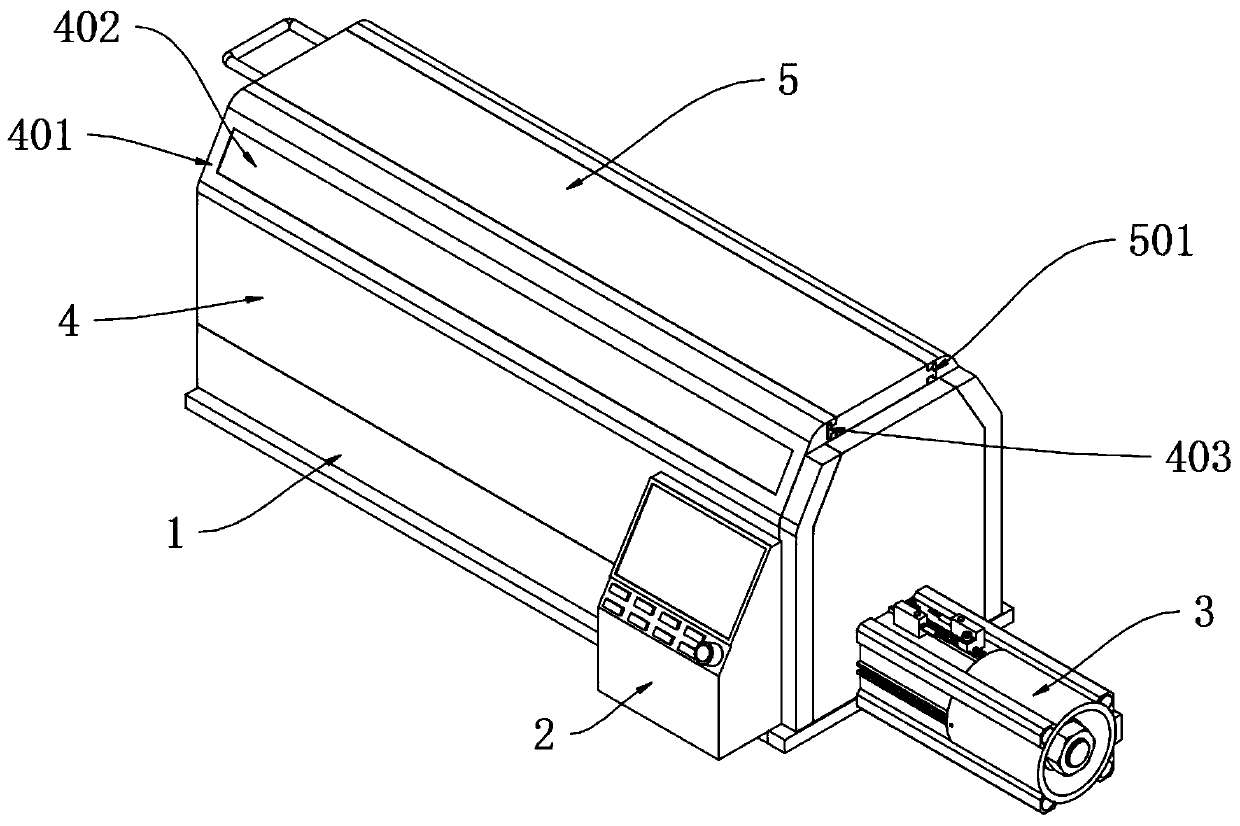

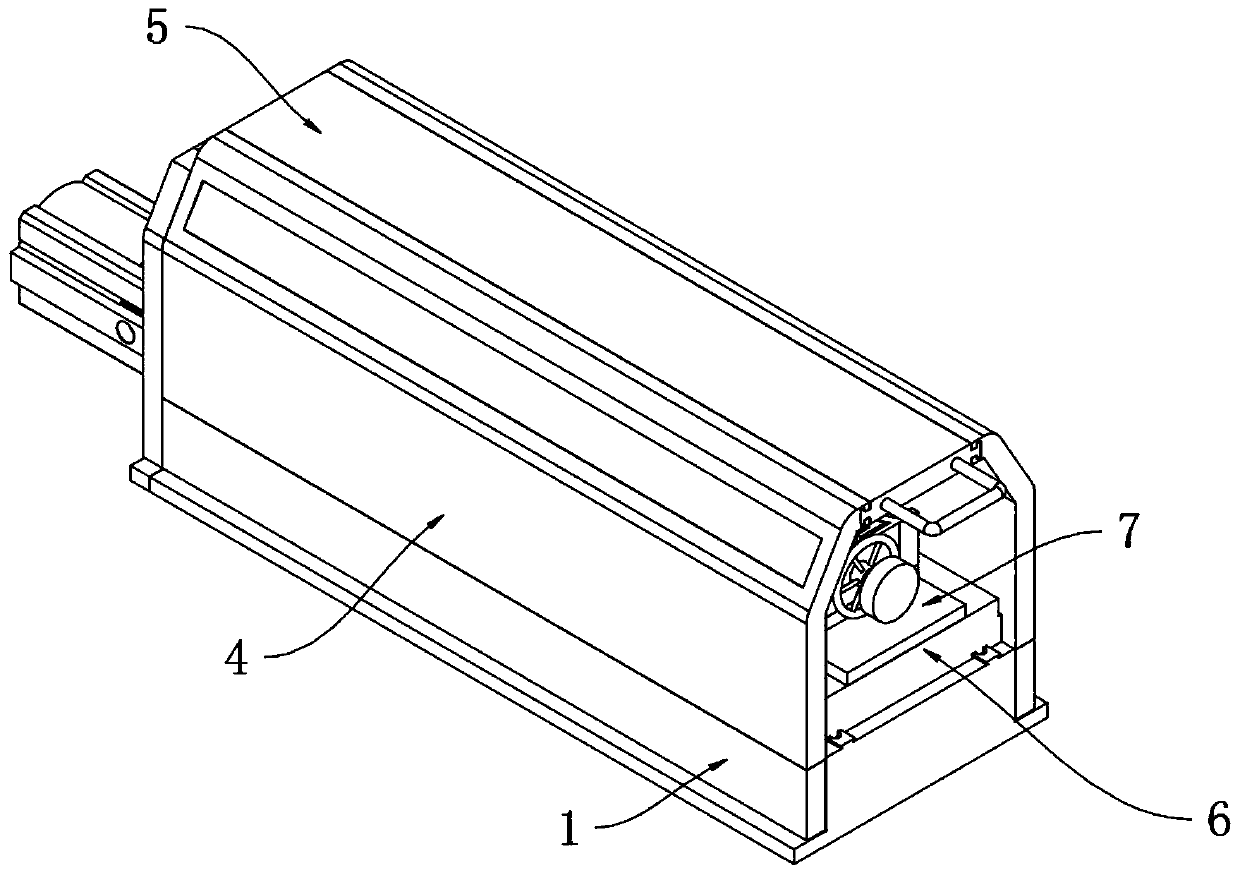

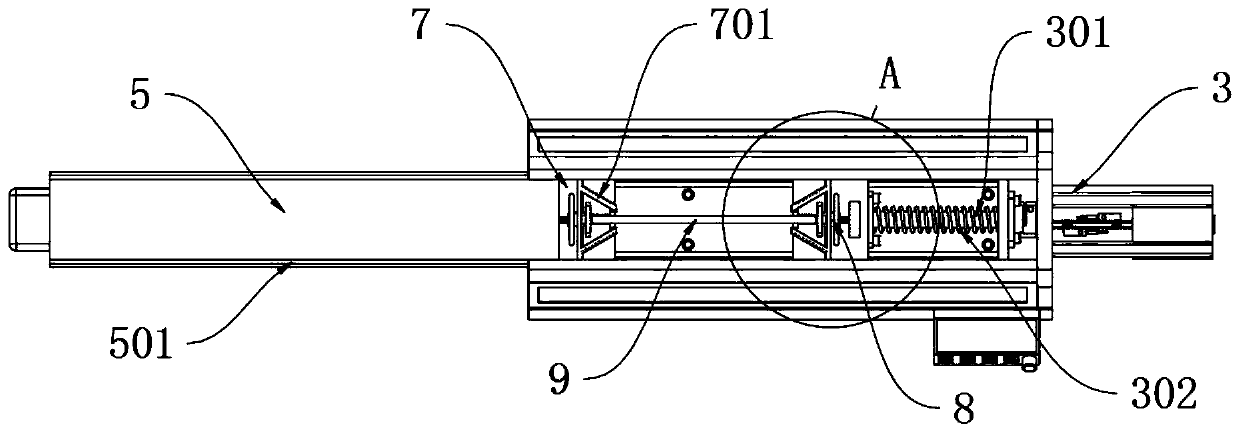

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The invention provides a steel cable strength testing device for coal equipment, which includes a detection platform 1; a control computer 2 is fixedly installed on the right end of the front side wall of the detection platform 1; a horizontal hydraulic mechanism 3 is fixedly installed on the right end of the detection platform 1; The mechanism 3 includes a connecting rod 301, a buffer spring 302 and a load sensor 303. The main body of the hydraulic mechanism 3 is an electric cylinder. The left end of the connecting rod 301 is fixedly connected with the lower end of the mobile platform 10, the upper ring of the connecting rod 301 is covered with a buffer spring 302, the left end of the buffer spring 302 is against the right side wall of the mobile platform 10, and the right end of the buffer spring 302 is against the right side wall of the mobile platform 10. On the right end side wall of the ejection chute 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com