Novel lower heating graphite crucible

A graphite crucible, a new type of technology, applied in the field of a new type of lower heating graphite crucible, can solve the problems of crucible damage, difficult temperature control, damage to the molten salt reaction system, etc., and achieve the effects of eliminating slagging, protecting the crucible, and improving metal purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

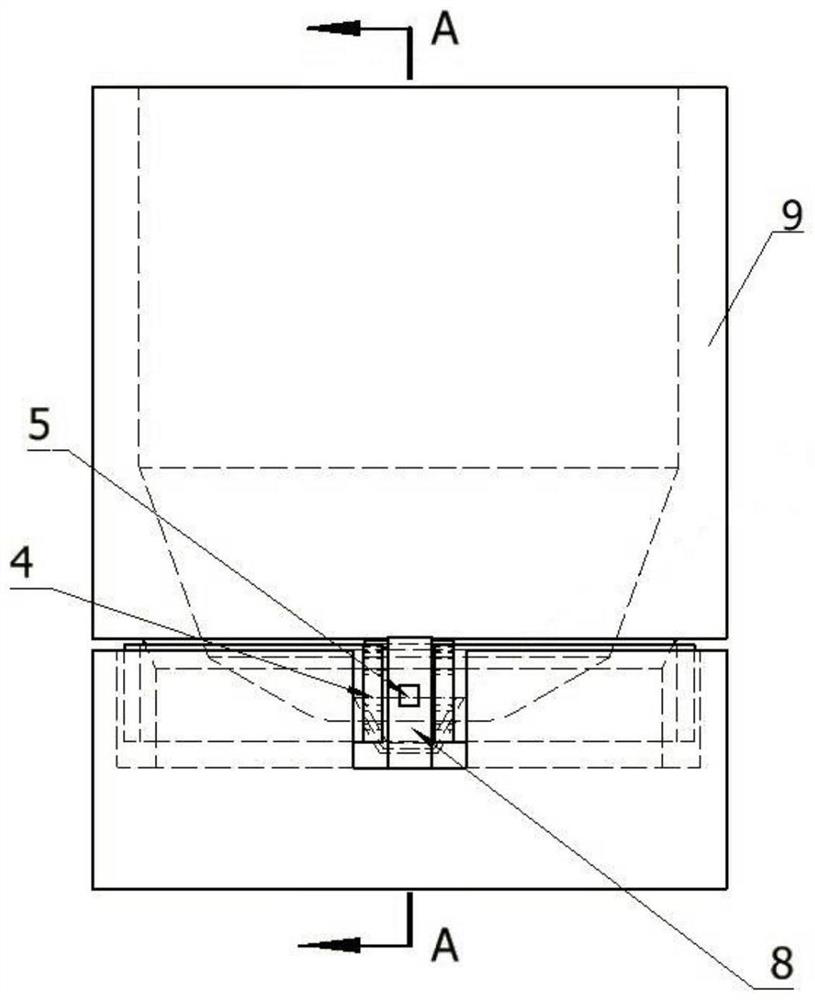

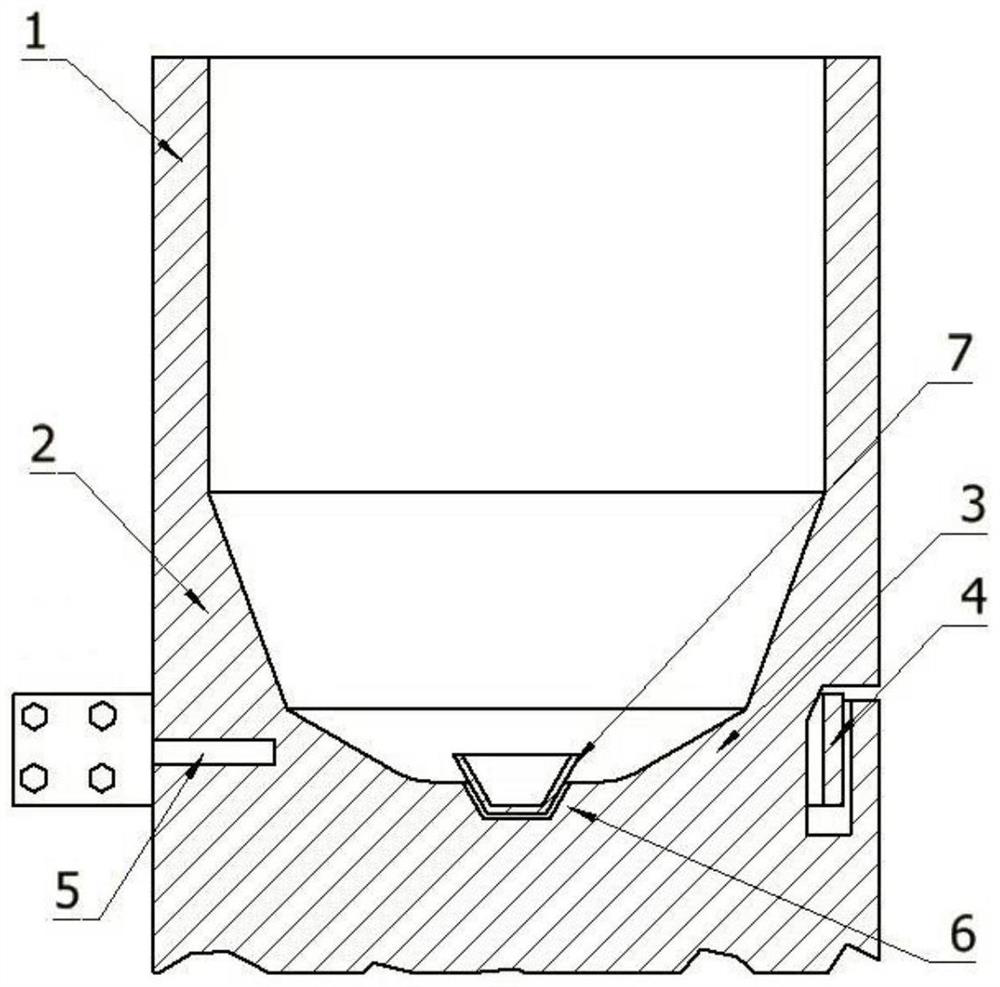

[0026] like Figure 1 to Figure 2 As shown, a new type of lower heating graphite crucible includes a graphite crucible 9, the outside of the graphite crucible 9 is a regular cylindrical structure and is divided from top to bottom into a cylindrical region 1 for placing raw materials and electrolyte, a graphite thickening region 2. The temperature sensing heating zone 3 and the truncated groove zone 6; the cylindrical zone 1 is equipped with anode sheets arranged circumferentially along the inner wall of the crucible; the inner bottom of the truncated truncated groove zone 6 is provided with a metal receiver 7, which can sense the temperature. The heating zone 3 is nested with an annular heating coil 4. The purpose of the annular heating coil 4 is to make the bottom of the crucible heated evenly; An insulating member 8 is nested between the ports, and an extension groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com