Tunnel furnace drying system

A technology of drying system and tunnel furnace, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of manpower and material cost, large amount of ammonia gas generation, and poor human health, so as to save manpower and The effect of material cost, improvement of uniformity and reduction of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

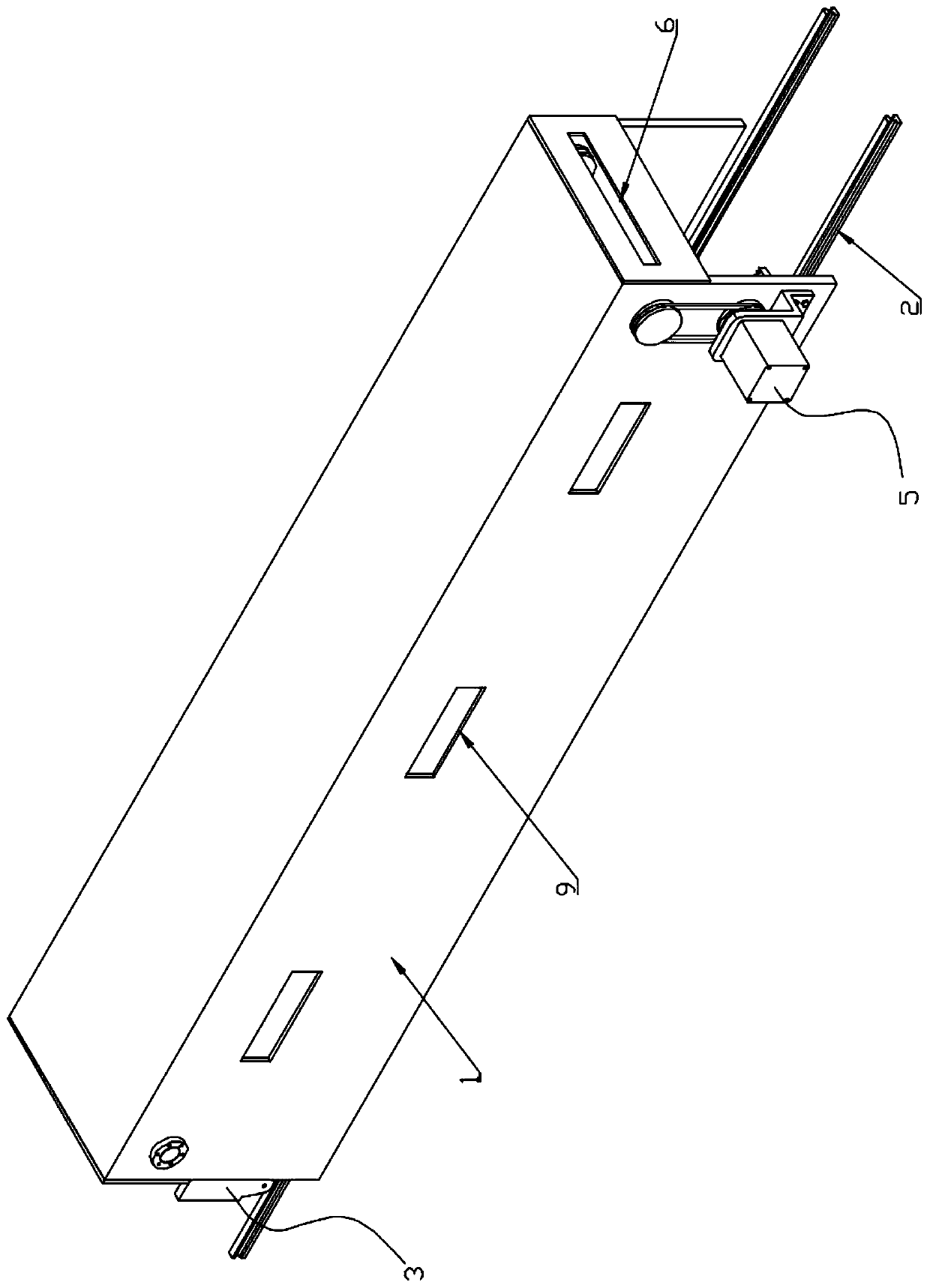

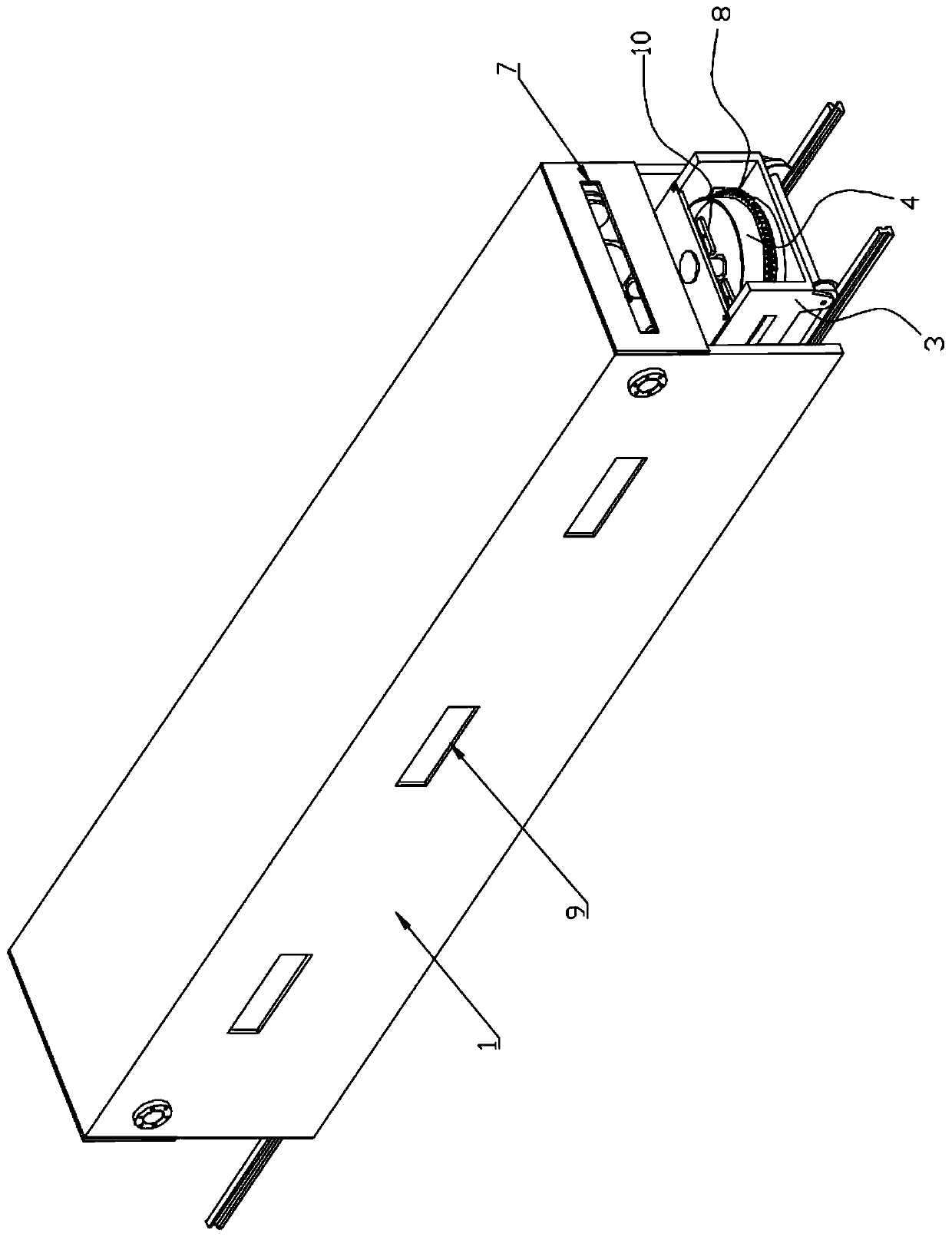

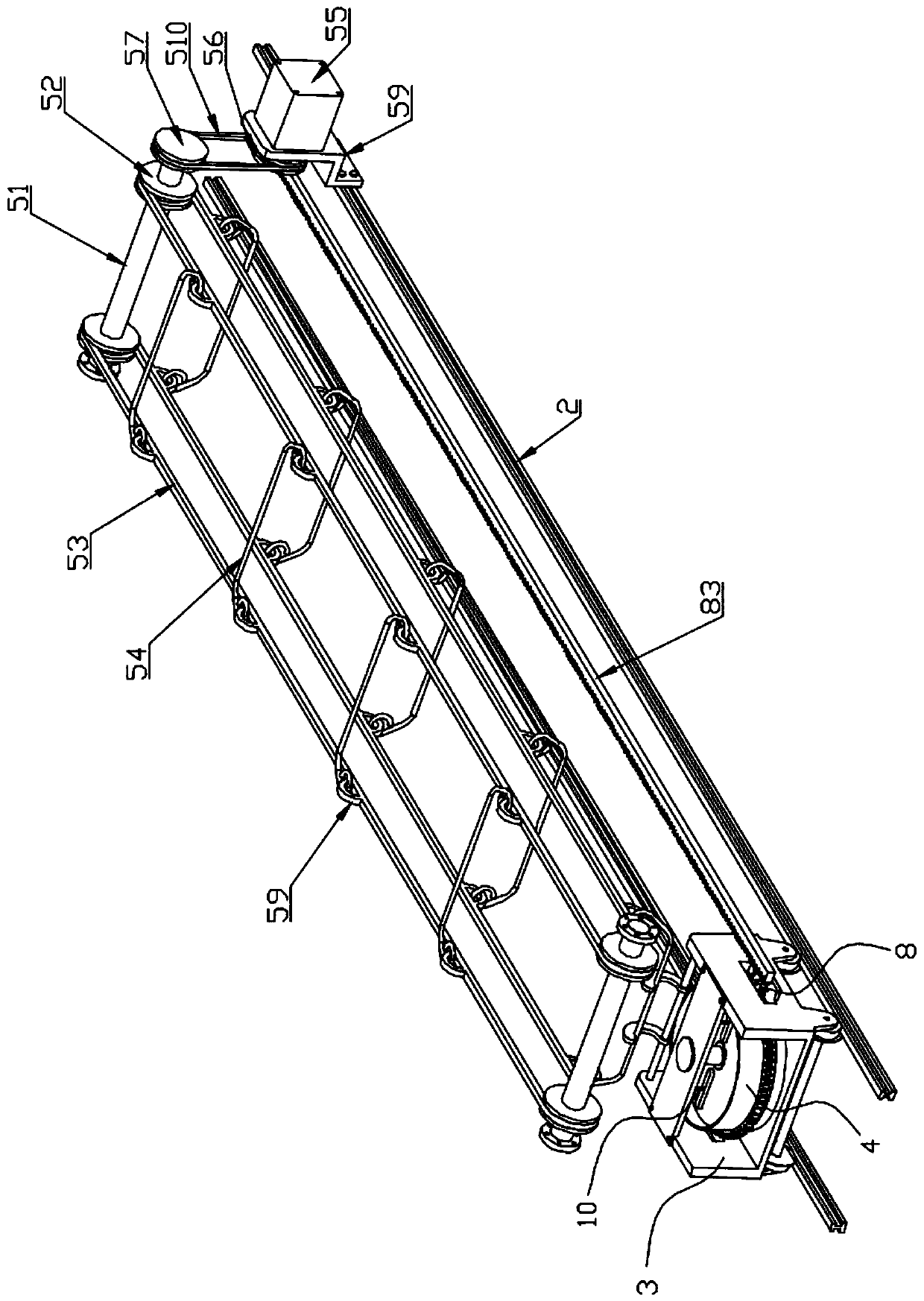

[0029] Such as Figure 1 to Figure 9 As shown, a tunnel furnace drying system includes a furnace body 1, a track 2, a charging car 3, a loading tray 4, and a drive mechanism 5. The furnace body 1 and the track 2 are all installed on the ground, and the track 2 Wrapped in the furnace body 1, the two ends of the furnace body 1 are respectively provided with an air inlet 6 and an air outlet 7, and the position of the air inlet 6 is located at the outlet end of the furnace body 1, and the air outlet 7 is also connected to the ammonia removal tower to To realize the treatment of waste gas, the charging car 3 is located on the track 2 and can travel along the track 2 under the action of the driving mechanism 5, and the loading tray 4 can rotate by means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com