Lubricating oil filler for printing machine net rack lifting rod and use method of lubricating oil filler

A printing machine network frame and lubricating oil technology, which is applied in the direction of lubricating oil container, engine lubrication, lifting frame, etc., can solve the problems of poor lubrication effect, short duration, insufficient lubrication, etc., and achieve good lubrication effect and continuous The effect of long time and accurate lubrication position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

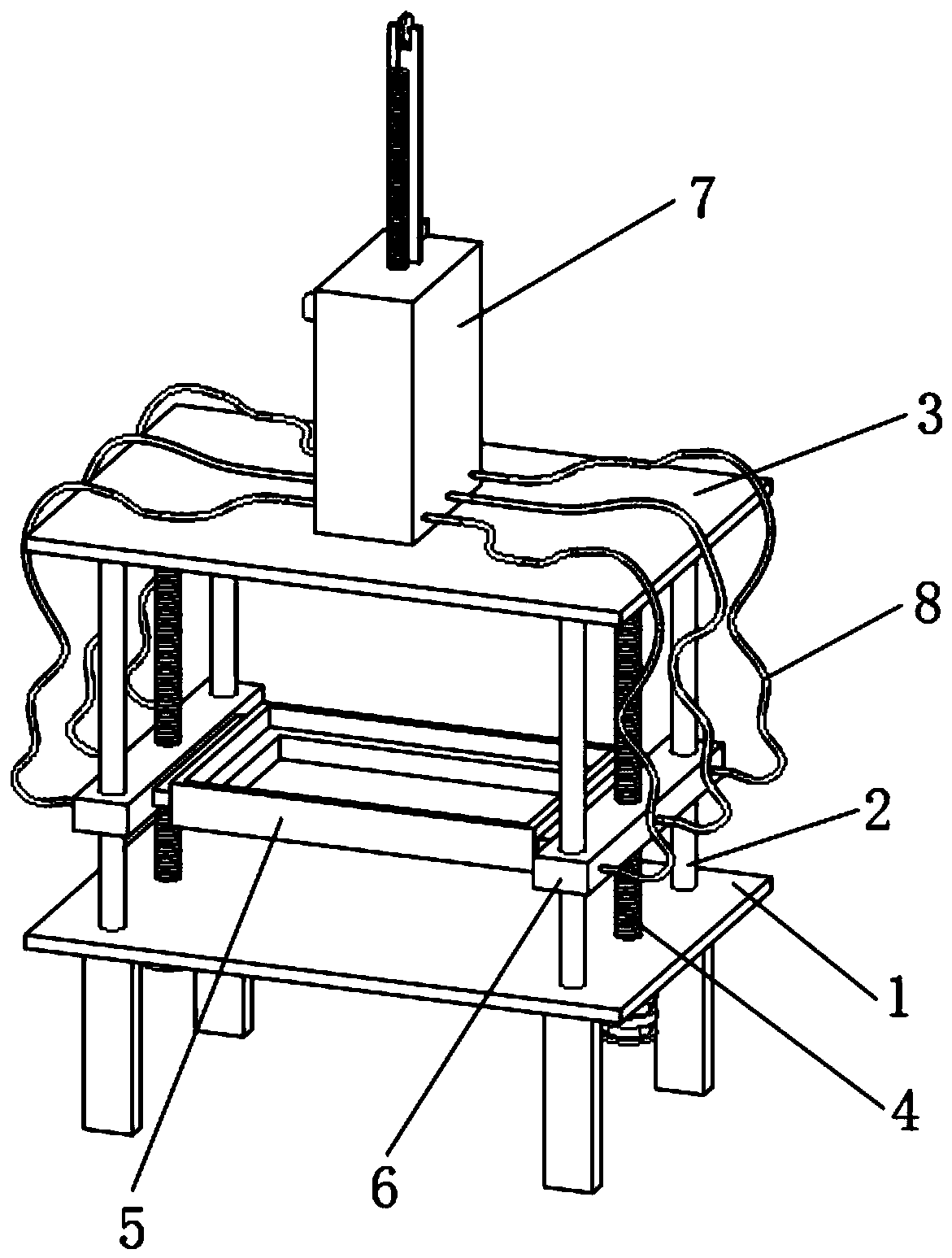

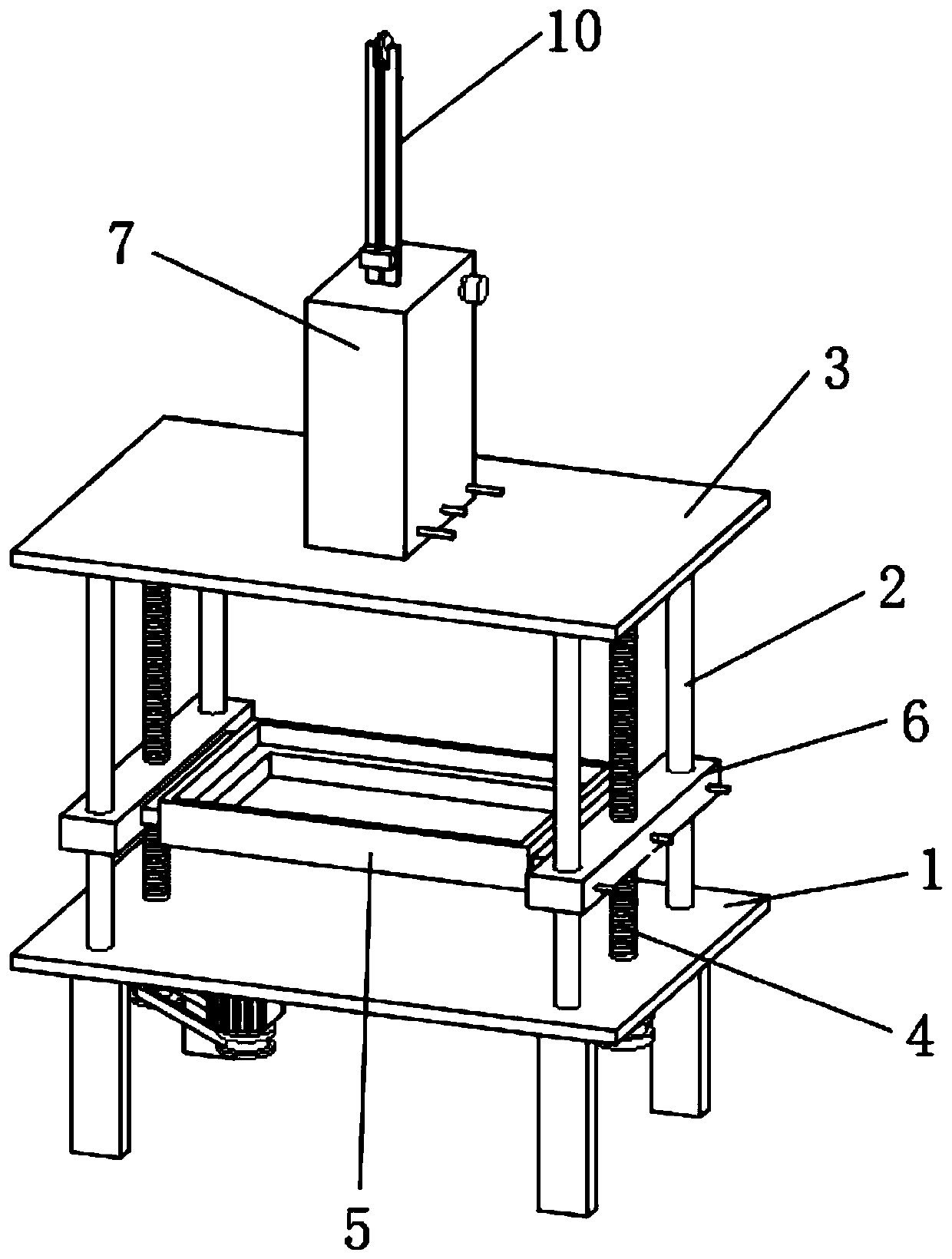

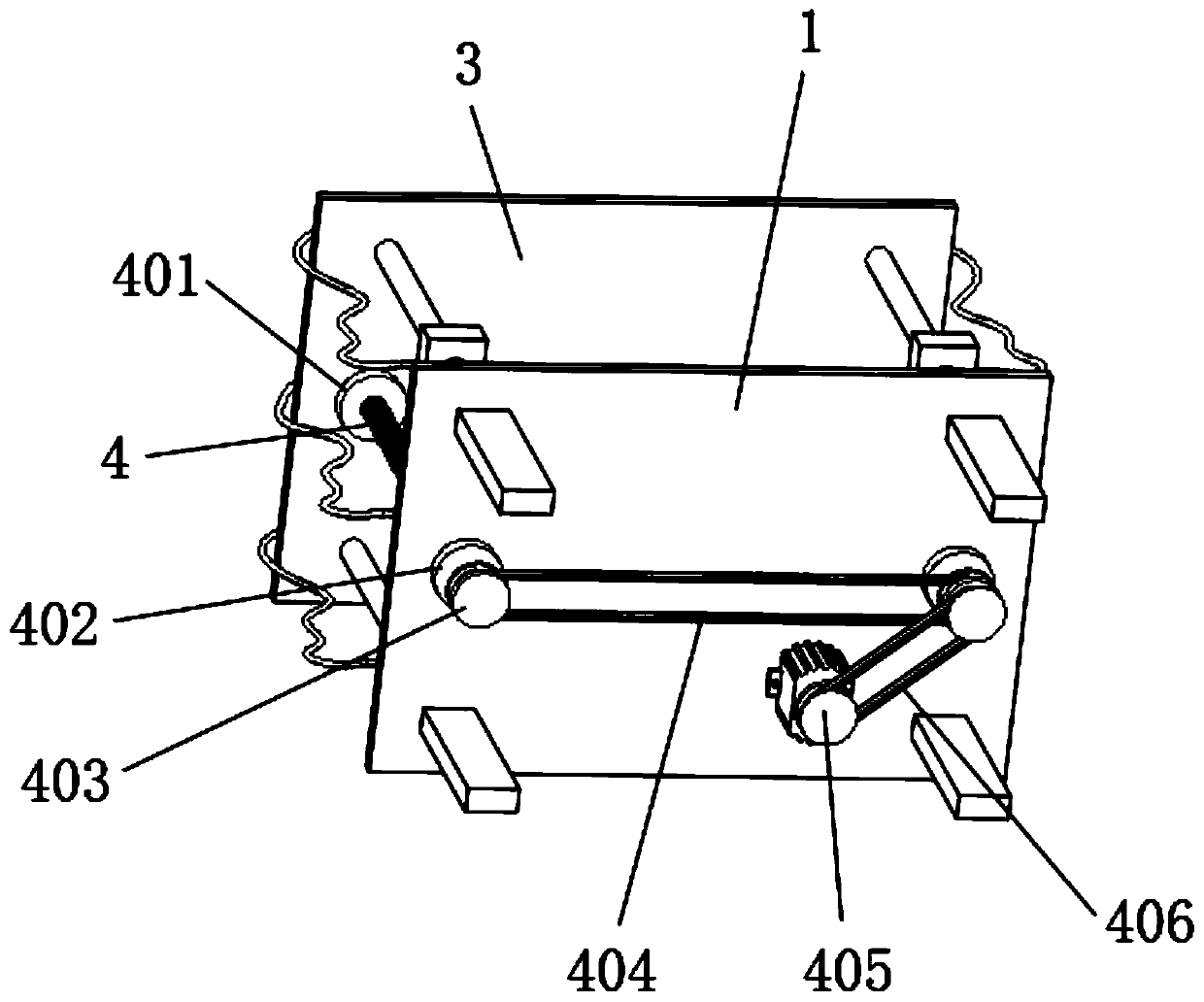

[0039] Example 1: See Figure 1-9, the present invention provides a technical solution: a lubricating oil filler for the lifting rod of the grid frame of a printing machine, including a bottom plate 1, a lifting support rod 2 and a top plate 3; the number of lifting support rods 2 is four groups and is fixedly connected to the bottom plate 1 At the four corners of the top, the top plate 3 is fixedly connected to the top of the lifting support rod 2, the size and shape of the bottom plate 1 and the top plate 3 are the same, every two groups of lifting support rods 2 are sleeved with lifting blocks 6, and the two groups of lifting blocks 6 are fixedly connected There is a grid main body 5, and the middle part of the upper surface of the lifting block 6 is provided with a screw hole, and the lifting block 6 is connected to the screw rod 4 through the internal thread of the screw hole, and the top of the screw rod 4 is connected to the lower surface of the top plate 3 through the f...

Embodiment 2

[0049] Example 2: See Figure 1-9 , the present invention provides a technical solution: a method for using a lubricating oil filler for a grid lifting rod of a printing machine. The method specifically includes the following steps:

[0050] Step S1: First, lubricating oil can be added to the oil box 7, specifically, the sealing cover 7031 is opened, and then the lubricating oil is added from the filling nozzle 703. At this time, the piston plate 9 is above the filling nozzle 703. Cover 7031 for sealing;

[0051] Step S2: By controlling the weight of the counterweight 1202 on the gravity block 12, the downward force of the piston plate 9 can be realized, and then the internal oil pressure of the oil storage chamber 701 can be adjusted to control the oil outlet rate of the oil outlet pipe 702. The counterweight 1202 will Press down the transmission rope 11, the transmission rope 11 pulls the sliding column 901 upwards through the fixed pulley 1001, and the sliding column 901 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com