A steel structure prefabricated building component

A building component and prefabricated technology, applied in building components, buildings, building structures, etc., can solve the problems of inconvenient reuse of steel structure components, insufficient stability of steel structure components, and inconvenience for users to use effects, etc., and achieve good thermal insulation. Thermal effect, improved shock absorption and thermal insulation effect, easy installation and assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

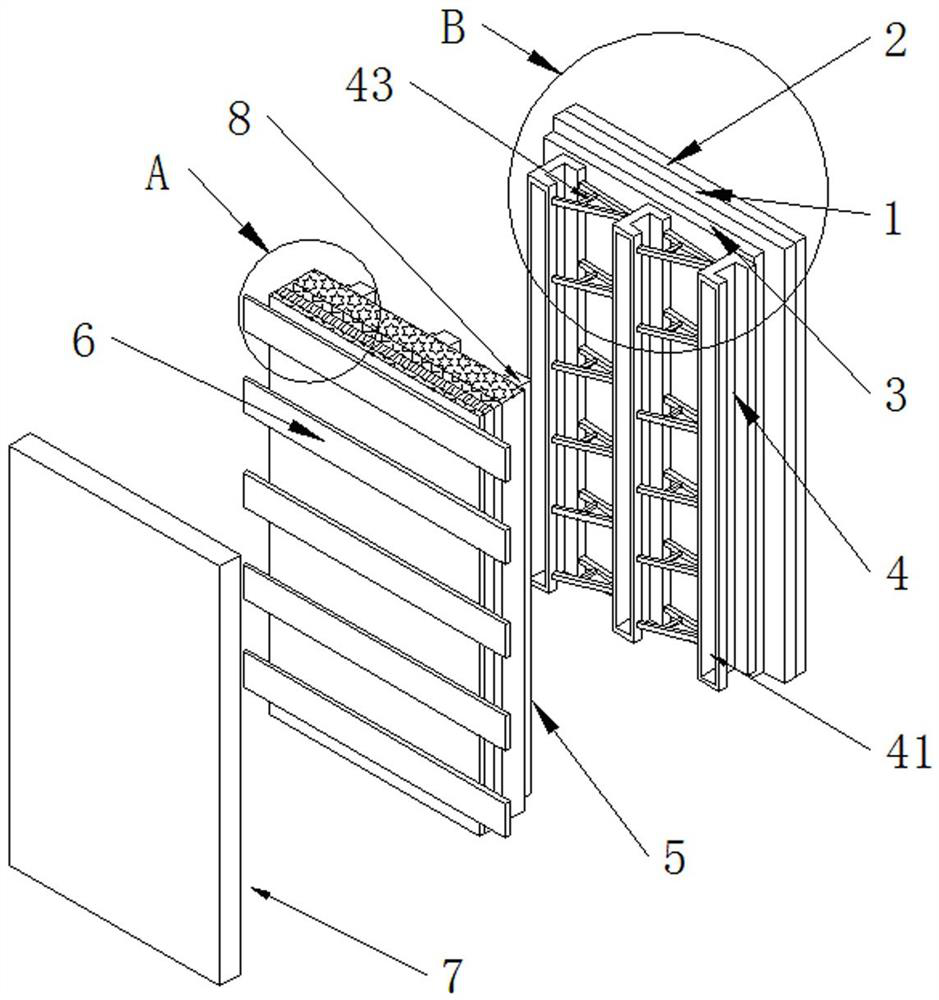

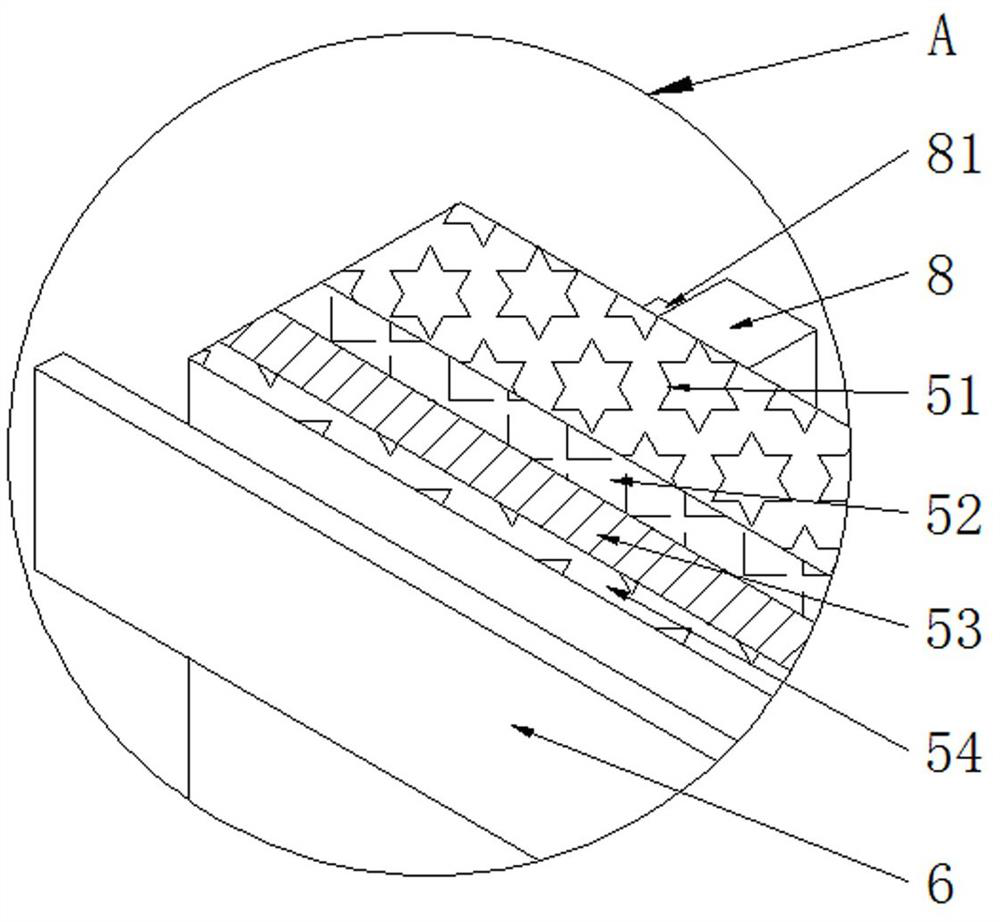

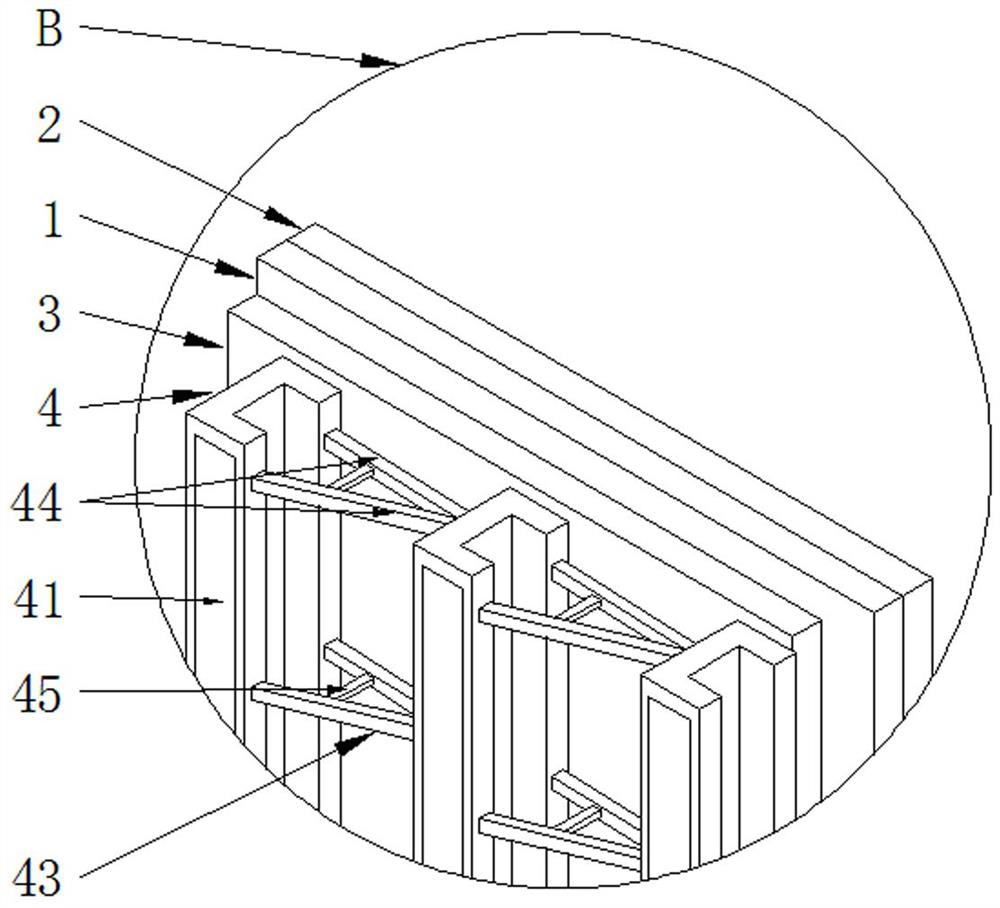

[0025] see Figure 1-5 , a prefabricated building assembly of steel structure, comprising a main steel plate 1, an interior wall panel 2, a vapor barrier panel 3, a protection panel 5 and an exterior wall panel 7 which are all vertically arranged; the interior wall panel 2 and the partition The steam panels 3 are respectively fixed on both sides of the main steel plate 1; the other end surface of the steam barrier 3 is fixed with a plurality of vertical support beams 4 at even intervals; the support beams 4 are far from the sides of the steam barrier 3 A fixed groove 41 is provided on one side end surface; a fixed block 8 is vertically fixed on the side end surface of the protective plate 5 close to the steam trap 3; a limit block 81 is fixed on one side end surface of the fixed block 8; The fixing block 8 cooperates with the limiting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com