Feeding device for continuous thermal cracking of biomass

A feeding device and thermal cracking technology, applied in the direction of biofuel, charging device, liquid hydrocarbon mixture preparation, etc., can solve the problems of poor fluidity of biomass, large angle of repose, hanging on the wall, etc., to avoid raw material tower bridge, The feeding process is stable and the effect of solving the difficulty of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A feed device for continuous thermal cracking of biomass proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims.

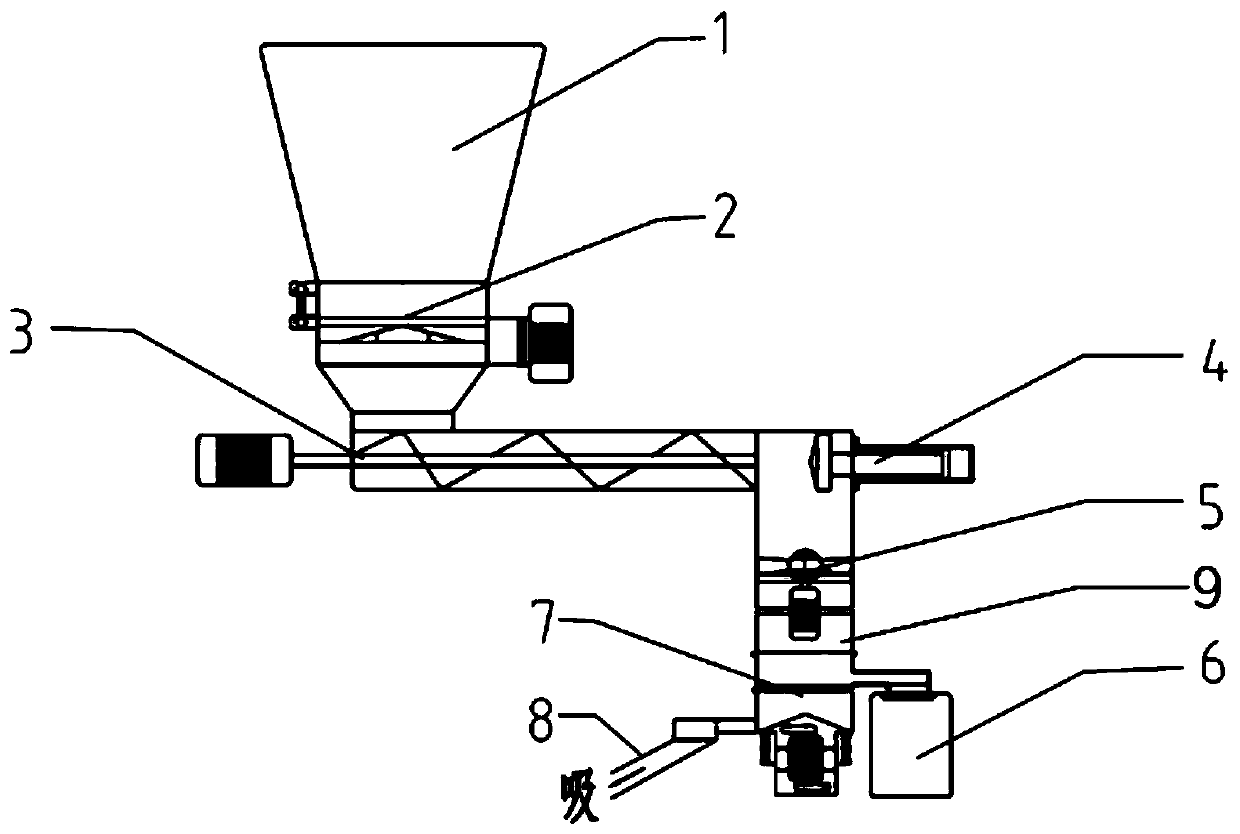

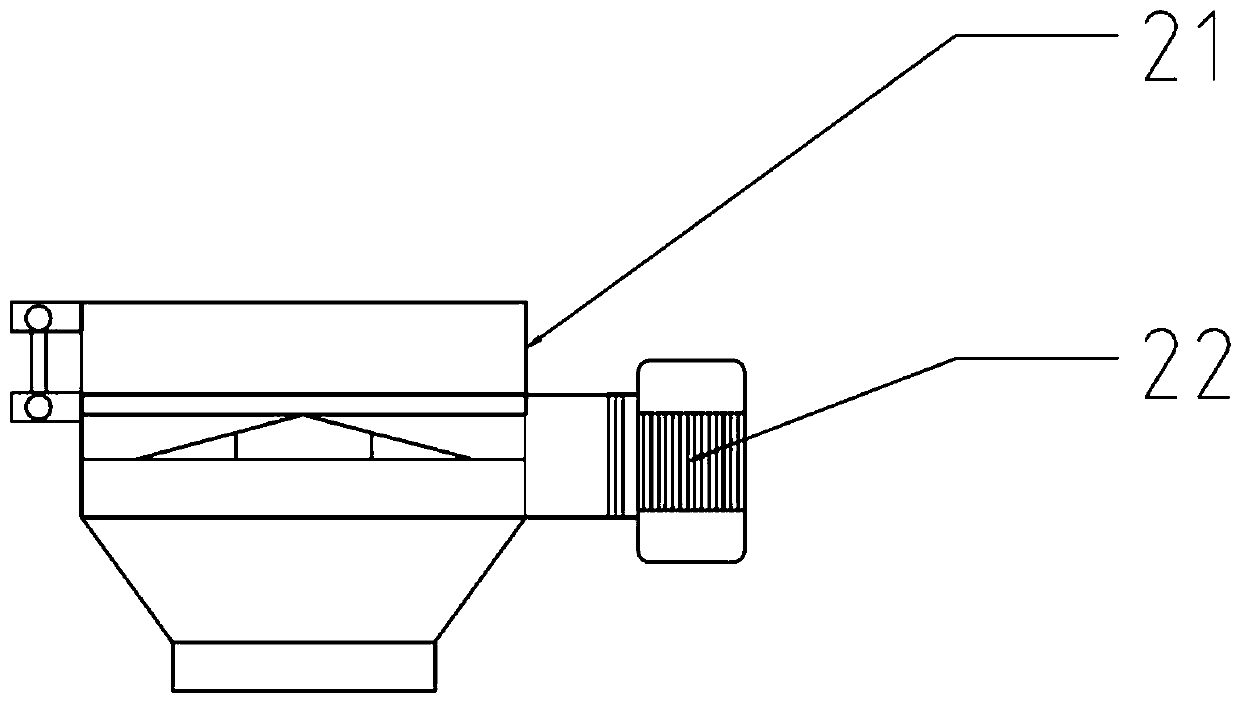

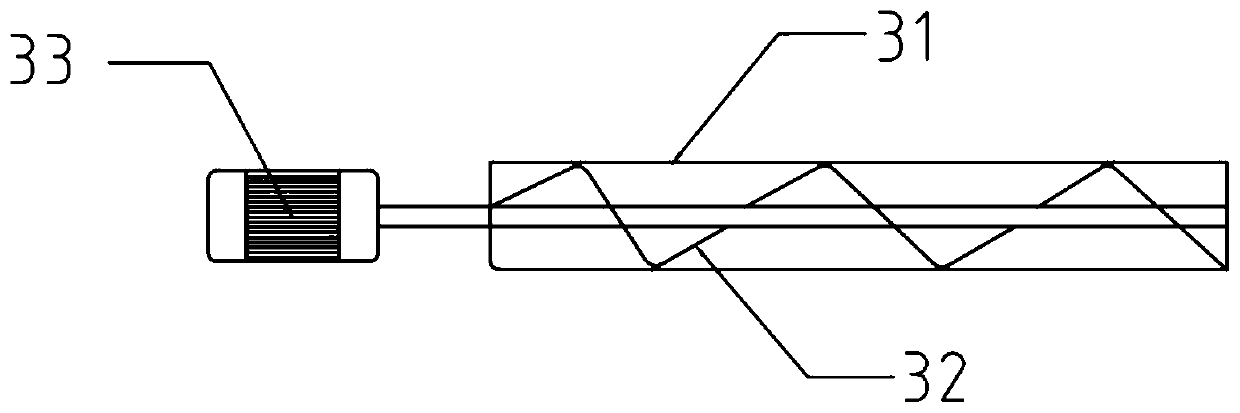

[0027] see Figure 1-Figure 6 , a feed device for continuous thermal cracking of biomass, comprising: an initial feed bin 1, a vibrating hopper 2, a screw quantitative feeding mechanism 3, a vibrating screen 7, and a negative pressure fine material feed pipe 8;

[0028] Among them, the vibrating hopper 2 is fixedly installed on the lower part of the initial silo 1; the inlet of the screw quantitative feeding mechanism 3 is fixed on the lower part of the vibrating hopper 2; 7 is arranged in the box body 9, and the bottom of the box body 9 is provided with a fine material outlet 92, and the negative pressure fine material feeding pipe 8 is arranged at the fine mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com