Wind power blade mold, preparation method of blade mold and mold surface monitoring system

A technology for wind power blades and molds, applied in the field of health monitoring of fiber composite materials, can solve problems such as offline detection, and achieve the effect of easy operation and one-time installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

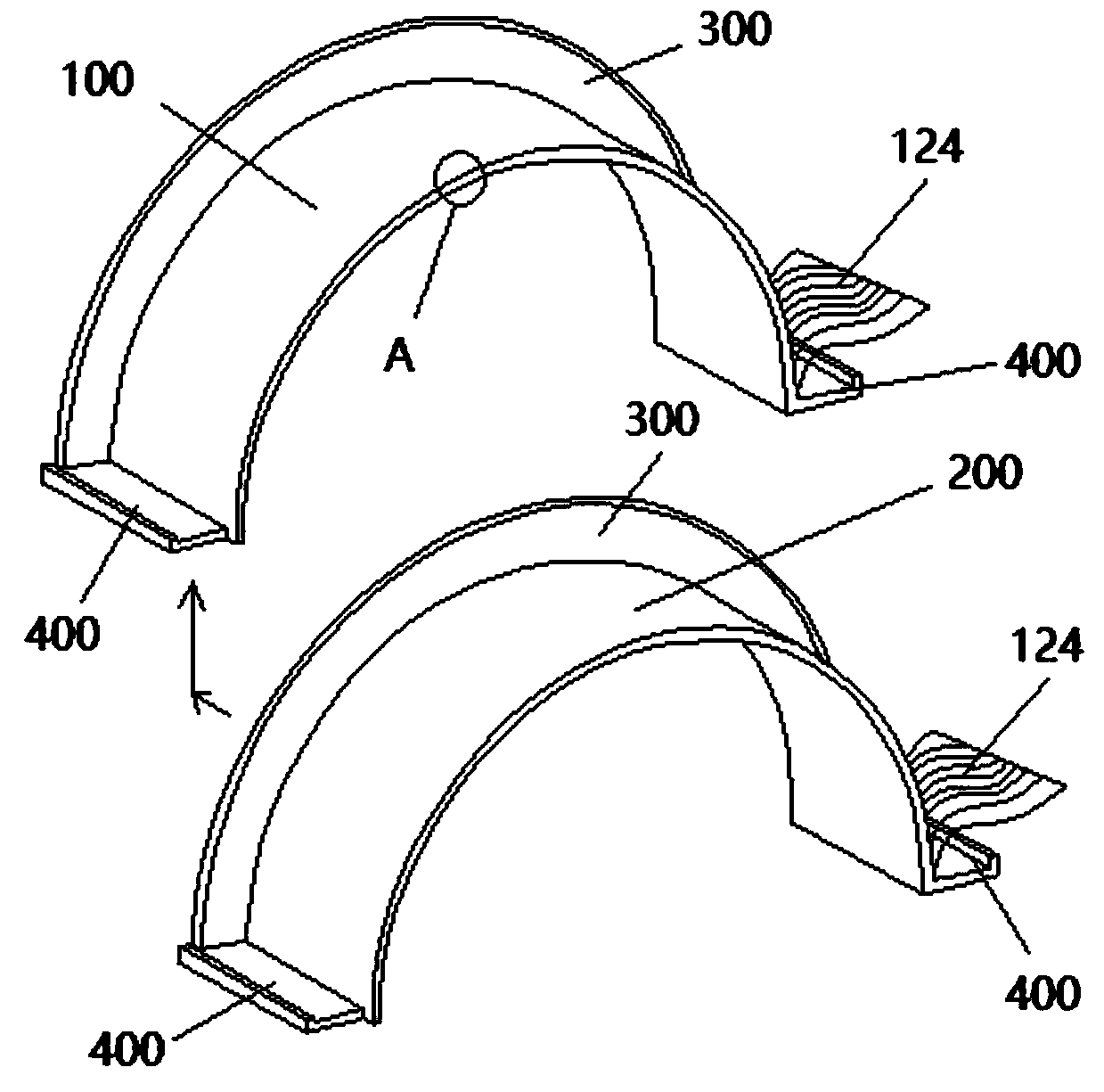

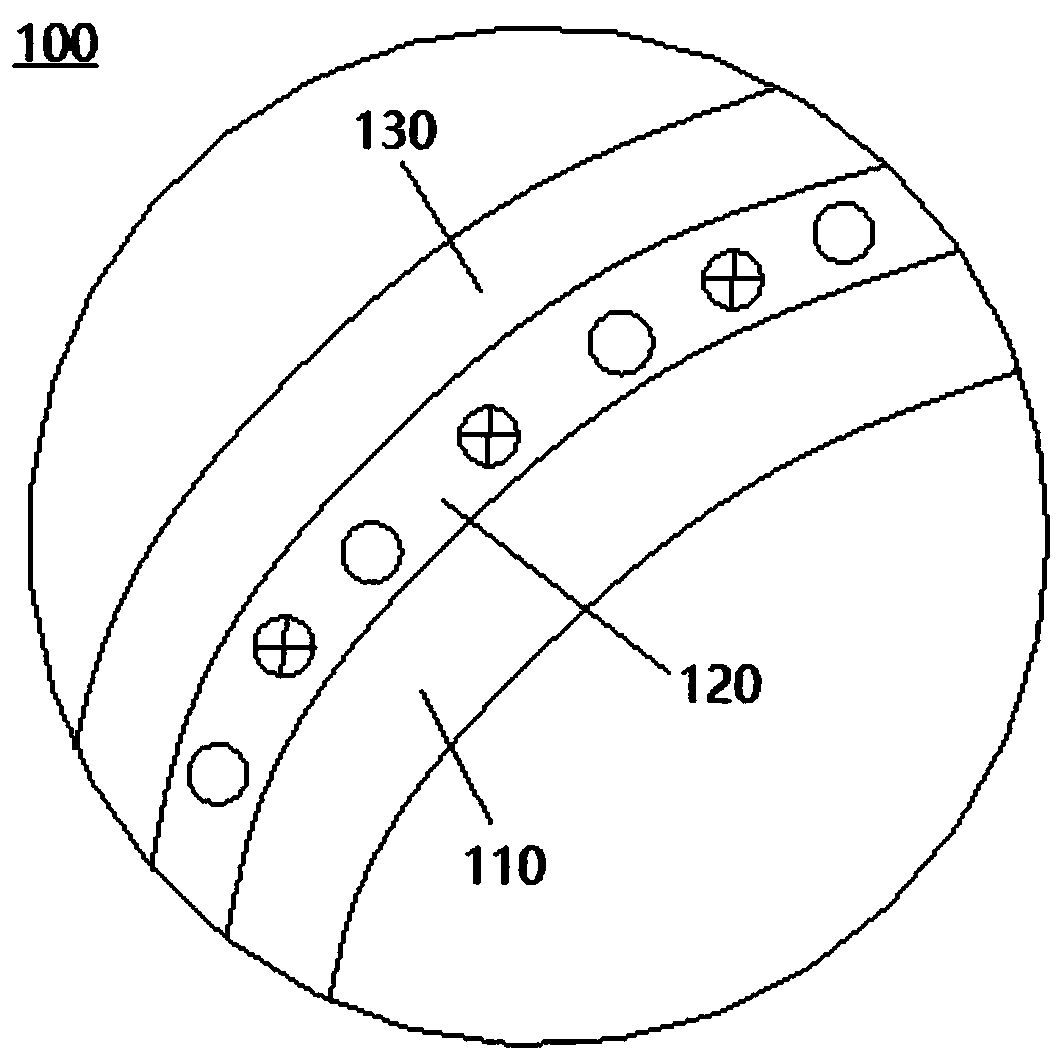

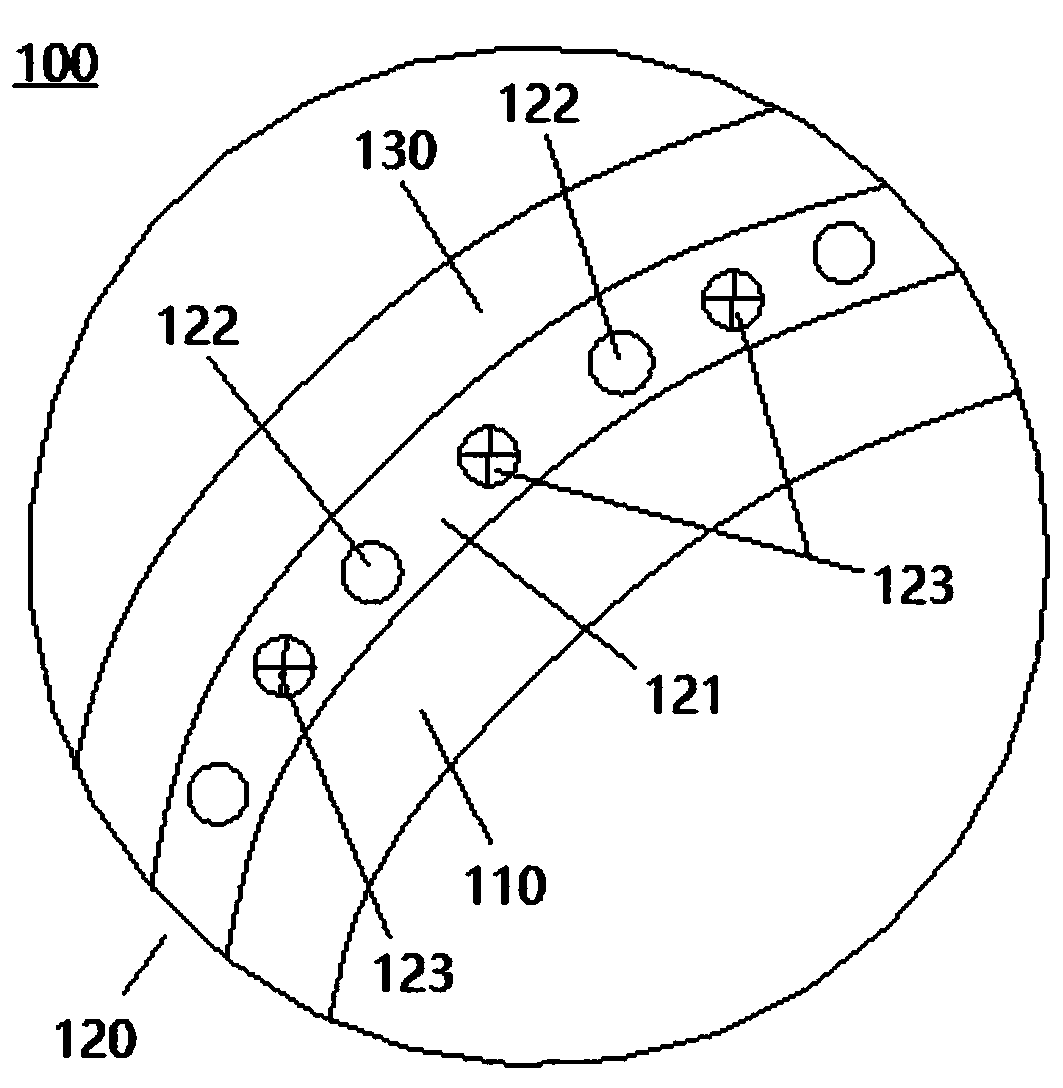

[0044] Such as figure 1 and figure 2 As shown, the present invention provides a wind power blade mold, including: an upper mold 100 and a lower mold 200; figure 2 As shown, the structure of the upper mold 100 includes: an inner structural layer 110, a heating layer 120, and an outer structural layer 130; the shape of the upper mold 100 is adapted to the shape of the upper surface of the wind turbine blade; The structure is the same as that of the upper mold 100; the shape of the lower mold 200 is adapted to the shape of the lower surface of the wind turbine blade; the upper mold 100 and the lower mold 200 are aligned and fastened; preferably, Such as figure 1 As shown, the blade root flange 300 is used for further positioning of the mold state after fastening; it should be noted that the above positioning method is not limited to the use of figure 1 For the blade root flange positioning method shown, applying other positioning methods in the present application according ...

Embodiment 2

[0061] This embodiment further provides a blade mold preparation method on the basis of embodiment 1, the method includes the following steps:

[0062] Step 1: Using the vacuum-assisted infusion process, the resin is poured on the multi-layer structure composed of surface felt, alkali-free cloth and multi-axial multi-layer fabric in order to prepare the inner structural layer of the blade mold; when the surface When the felt layer is composed of multiple surface felts, the connection mode between two adjacent surface felts is lap joint; The connection mode is lap joint; when the multi-axial multi-layer fabric layer is composed of multiple multi-axial multi-layer fabrics, the connection mode between two adjacent multi-axial multi-layer fabrics is lap joint; the blade The number of inner structure layers in the mold is two, and the shapes are adapted to the shapes of the upper and lower sides of the blades respectively, so as to obtain the finished products of the inner structur...

Embodiment 3

[0082] This embodiment further provides a mold profile monitoring system on the basis of the above embodiments, including: a wind power blade mold and a fiber grating demodulator; the wind power blade mold is the wind power blade mold described in Embodiment 1, or A wind power blade mold manufactured according to the method described in Example 2; the fiber grating demodulator is connected to the fiber grating signal of the wind power blade mold through an optical fiber.

[0083] Further, in one of the preferred technical solutions of this embodiment, a sealed bag is provided at the fiber interface between the fiber grating demodulator and the fiber grating. The transmission lines and lead joints of the packaged optical fiber grating sensor are sealed and protected by a sealed bag, which can prevent the optical fiber interface from being polluted.

[0084] As shown in Figure 6, the core working components of the mold surface monitoring system mainly include three parts: the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com