Solder and insulation container welded by means of same

A thermal insulation container and solder technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor welding fastness of titanium and stainless steel, poor quality of thermal insulation containers, etc., and achieve effective connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

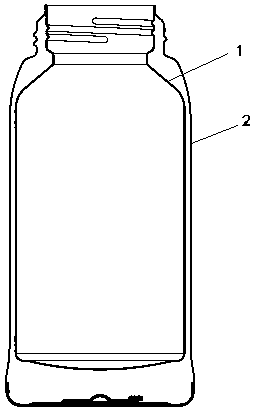

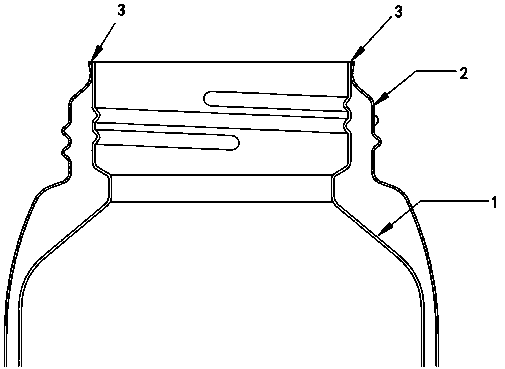

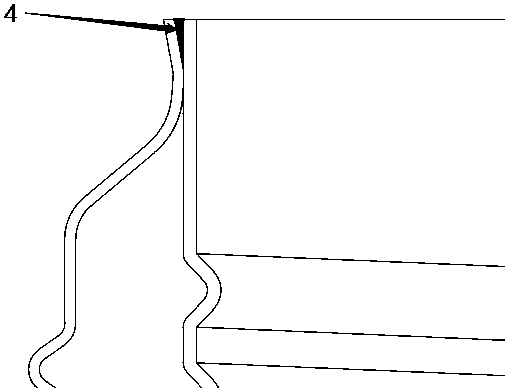

[0027] A thermos cup has a titanium inner liner and a SUS304 stainless steel outer shell. After assembly, a welding cavity is left between the inner liner and the outer shell. The width of the welding cavity is 0.1mm, and vacuum brazing is carried out by solder. The solder is prepared by mixing 5% of 300-mesh zirconium powder, 9% of 300-mesh nickel powder, 78% of 300-mesh titanium powder and 8% of 300-mesh copper powder according to weight percentage.

[0028] The temperature of the vacuum brazing is 905°C, and the edge welding structure is adopted (inner tank and the mouth of the shell are welded together), and the holding time of the vacuum brazing is 50 minutes.

Embodiment 2

[0030] A thermos cup has a titanium liner and a SUS305 stainless steel shell. After assembly, a welding cavity is left between the liner and the shell. The width of the welding cavity is 0.5mm, and vacuum brazing is carried out by solder. The solder is prepared by mixing 5% of 800-mesh zirconium powder, 9% of 800-mesh nickel powder, 78% of 800-mesh titanium powder and 8% of 800-mesh copper powder according to weight percentage.

[0031] The temperature of the vacuum brazing is 930°C, and the welding structure is adopted (one of the mouth of the inner tank or the shell is crimped and welded with the mouth), and the holding time of the vacuum brazing is 70 minutes.

Embodiment 3

[0033] An inner tank of a thermal insulation container, the inner tank is compositely connected by titanium material and SUS309 stainless steel material through vacuum brazing to form a composite inner tank, the titanium material is on the inside, the stainless steel material is on the outside, and the outside of the composite inner tank can be set without modification or plastic case. The welding cavity (welding seam) of the welding part of the composite liner is 3.0mm. The solder is prepared by mixing 5% of 500-mesh zirconium powder, 9% of 500-mesh nickel powder, 78% of 500-mesh titanium powder and 8% of 500-mesh copper powder according to weight percentage.

[0034] The temperature of the vacuum brazing is 920° C., and the holding time of the vacuum brazing is 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com