A method of ultra-high-speed laser cladding complex curved surface of revolution

A technology of laser cladding and complex curved surfaces, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve problems such as different surface cladding line speeds, huge differences in cladding quality and coating thickness, and achieve quality Good, guaranteed cladding efficiency, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

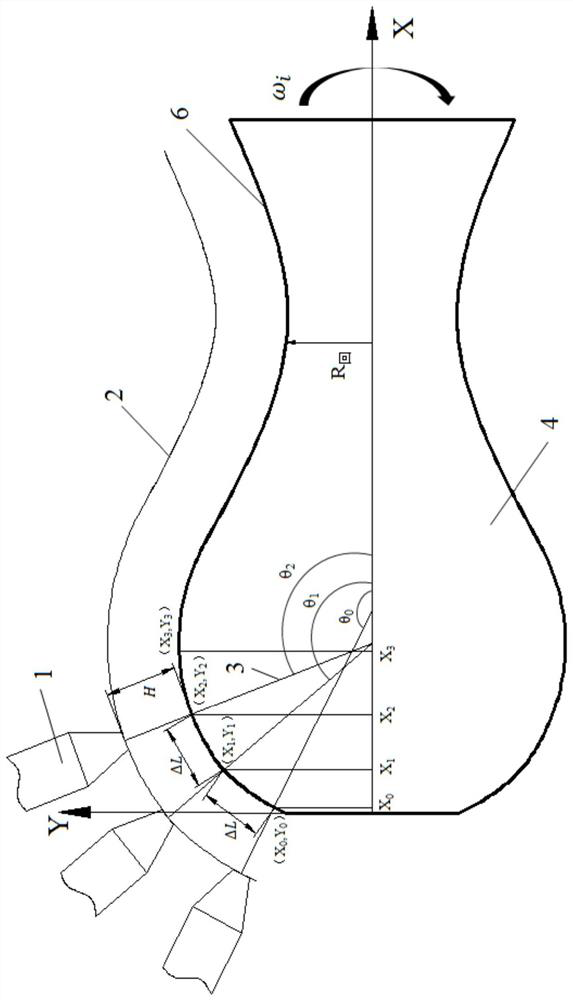

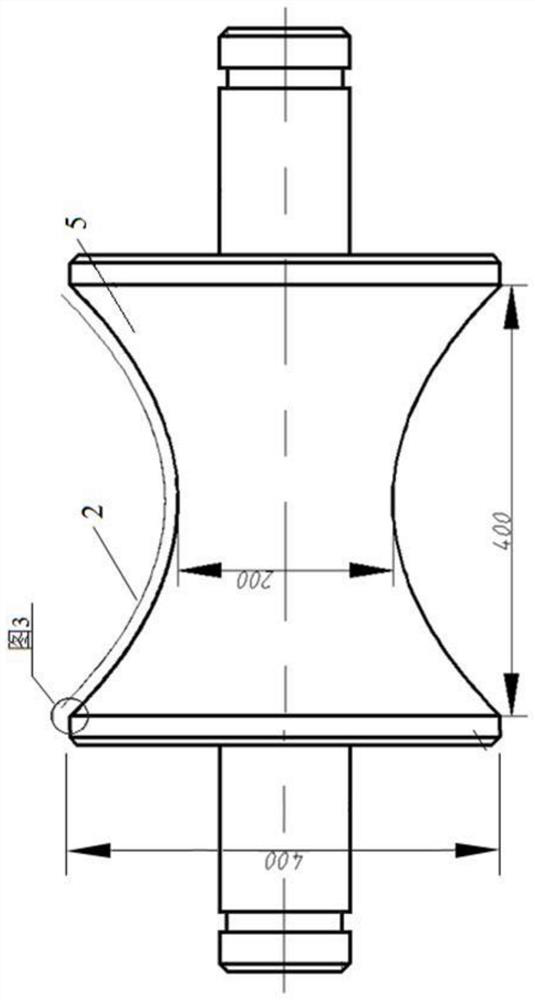

[0047] like figure 2 As shown in the figure, the cross-sectional profile of the to-be-clad surface of a certain roller part is approximately a parabola, the diameter of both ends is Φ400mm, the middle diameter is Φ200mm, and the length is 400mm. The surface is subjected to single-layer ultra-high-speed laser cladding and cladding powder. Iron-based stainless steel powder is selected, and the cladding process is carried out through the following process steps.

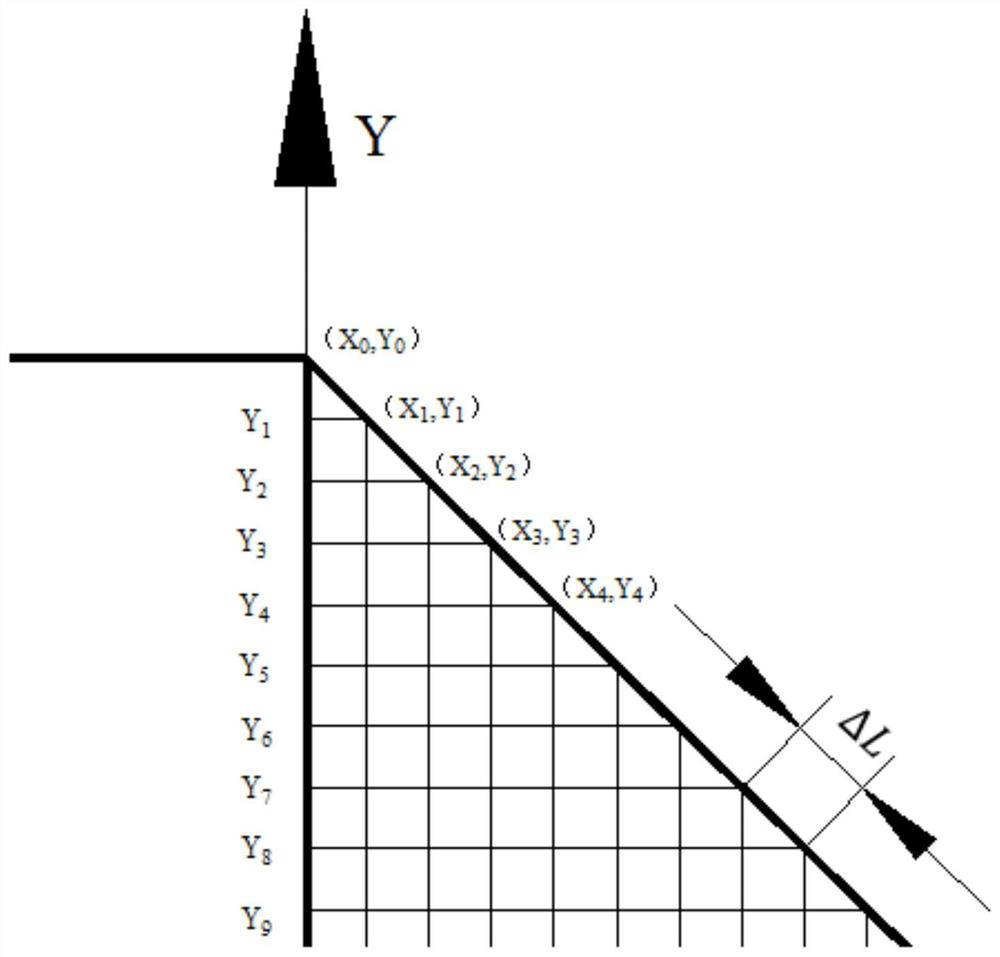

[0048] First, set the cladding line speed V=30 / min=500mm / s, laser beam power P=5kW, ultra-high-speed laser cladding defocus amount H=12mm, cladding overlap ratio δ=0.6 and ultra-high-speed laser cladding according to process requirements. Cladding single track width D L After many tests, it is 2.5mm; the cladding path node is set on the bus line of the axial cross-sectional profile of the complex curved body of revolution; by controlling the rotational angular velocity ω of the workpiece during the cladding process i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com