Ru-ZnO photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and ruthenium chloride, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., which can solve the problems of low efficiency of photocatalytic degradation of methane, poor cycle stability of catalysts, and limitation of full utilization of solar energy, etc. problems, achieve high-efficiency catalytic performance and cycle stability, improve photocatalytic efficiency, good photocatalytic activity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] To achieve the above objectives, the present invention provides a method for preparing Ru-ZnO photocatalyst, which includes the following steps:

[0025] (1) Mixing zinc salt with oxalic acid and water, precipitation reaction to obtain zinc oxalate;

[0026] (2) subjecting the zinc oxalate obtained in the step (1) to the first annealing to obtain ZnO;

[0027] (3) Mixing the ZnO obtained in step (2) with ruthenium chloride and water to perform an oxidation-reduction reaction to obtain a precursor;

[0028] (4) The precursor obtained in the step (3) is subjected to a second annealing to obtain a Ru-ZnO photocatalyst.

[0029] In the present invention, zinc salt is mixed with oxalic acid and water, and zinc oxalate is obtained by precipitation reaction. In the present invention, the operation of mixing the zinc salt with oxalic acid and water is not particularly limited, and a mixing technical solution well known to those skilled in the art may be used. In the present invention, ...

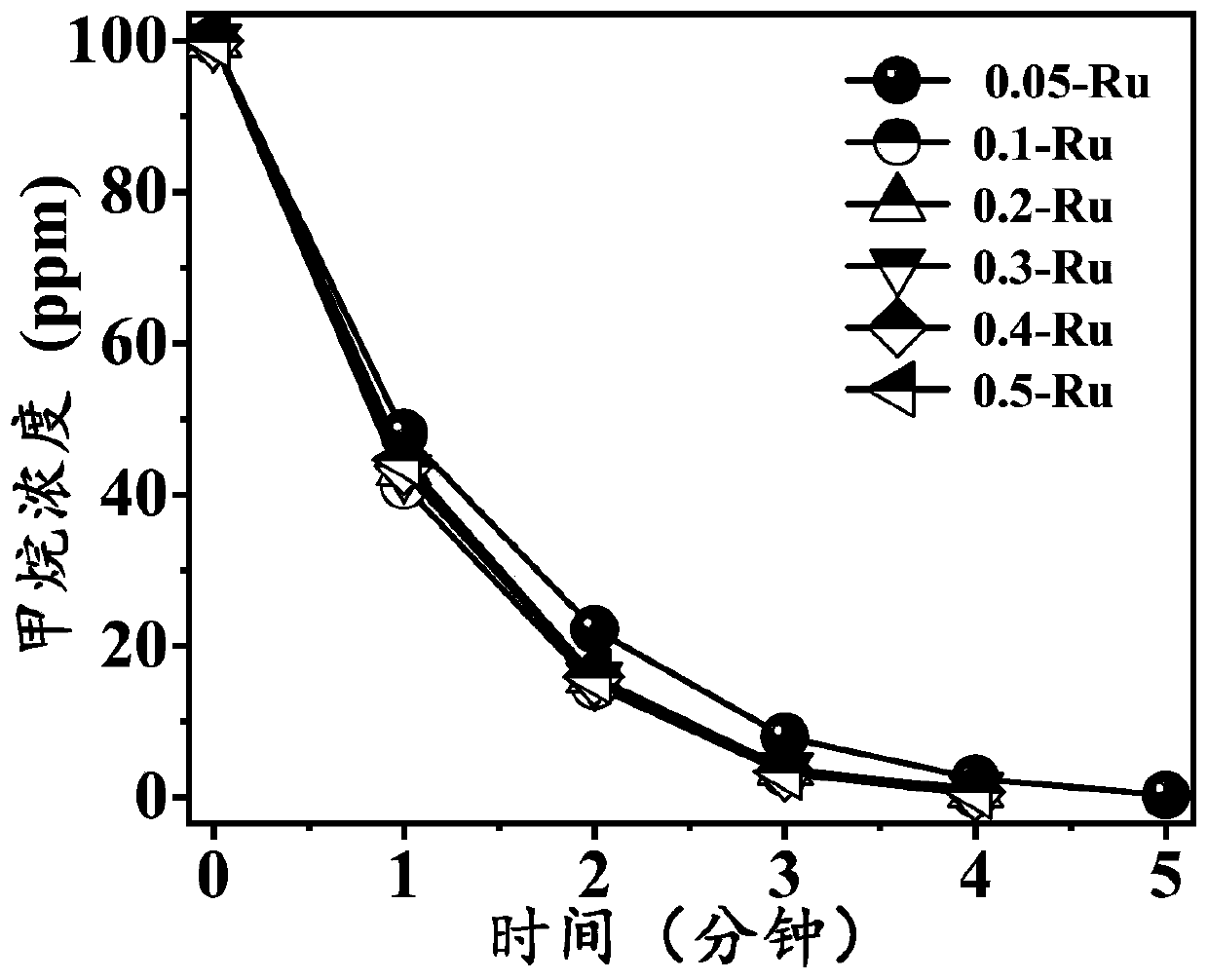

Embodiment 1

[0053] Add 10g of zinc acetate dihydrate to 100mL of deionized water, stir until completely dissolved, add 20g of oxalic acid dihydrate to the above solution under stirring conditions (wherein the weight ratio of zinc acetate dihydrate to oxalic acid dihydrate is 1:2 , Stirred for 30 minutes to obtain zinc oxalate precipitate. Then the zinc oxalate precipitate was filtered with suction and washed with sufficient water, and the zinc oxalate was dried at 100°C for 5h. Zinc oxalate was ground into powder and placed in the air at 350°C Anneal for 6h to obtain ZnO powder.

[0054] Disperse 1 g of the above ZnO powder in 75 mL of deionized water ultrasonically, and stir until a uniformly dispersed suspension is formed. Then, the prepared ruthenium chloride solution (0.0964mol / L) was added, and the amount of ruthenium chloride added was 102.69 μL (the weight ratio of Ru element to ZnO in the added ruthenium chloride was 0.1:100). After adding the ruthenium chloride solution, stirring f...

Embodiment 2

[0056] The method of Example 1 was used to prepare ZnO.

[0057] Disperse 1 g of the above ZnO powder in 75 mL of deionized water ultrasonically, and stir until a uniformly dispersed suspension is formed. Then the prepared ruthenium chloride solution (0.0964mol / L) was added, and the amount of ruthenium chloride added was 51.34 μL (the weight ratio of Ru element to ZnO in the added ruthenium chloride was 0.05:100). After adding the ruthenium chloride solution, stirring for 3 hours, and then standing for 1 hour, the resulting precipitate was suction filtered and dried at 60° C. for 10 hours. Grind the dried product into powder, and anneal it in air at 200°C for 30 minutes to obtain 0.05-Ru-ZnO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com