An automatic measurement matching system and a plunger pump gasket assembly method

An automatic measurement and assembly technology, applied in the direction of measuring devices, assembly machines, metal processing equipment, etc., can solve the problems of wrong assembly and missing assembly, unable to realize the traceability of the assembly process, etc., to increase the yield, reduce labor intensity, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

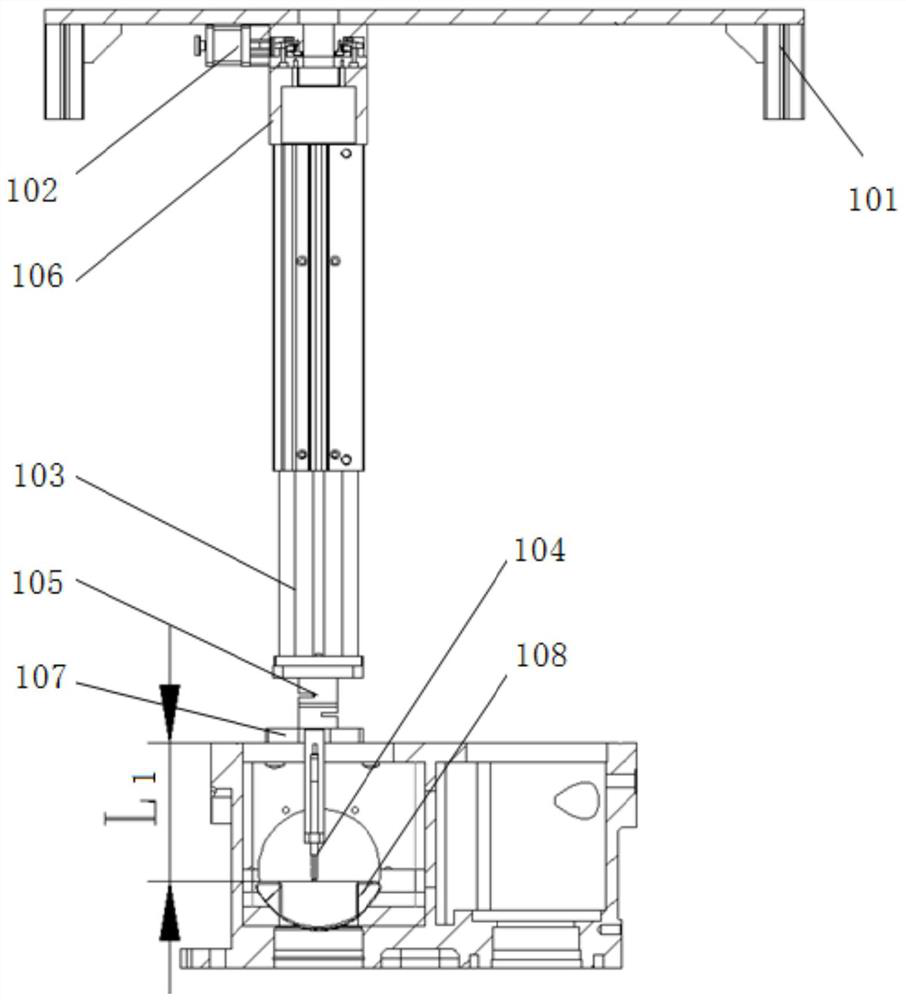

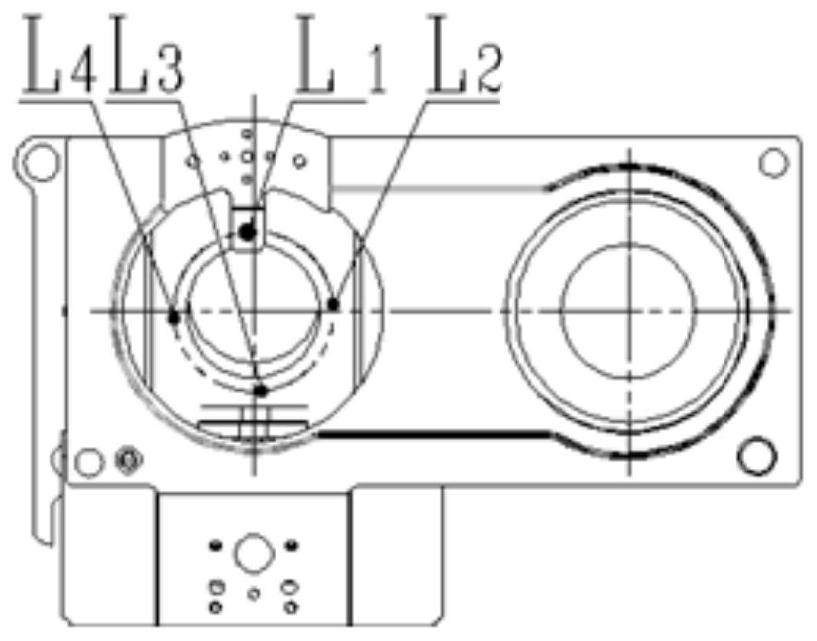

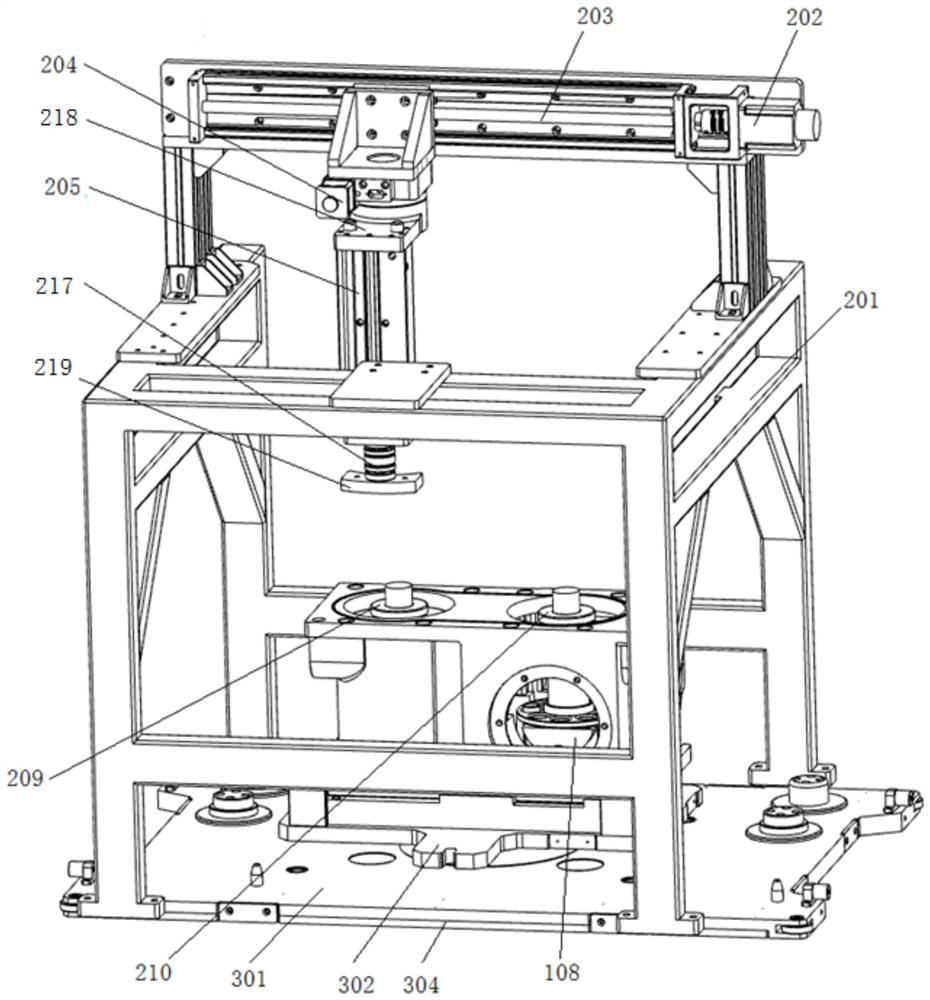

[0055] The invention provides an automatic measurement matching system, which can complete the measurement of the parallelism of the adjustable swash plate of the plunger pump, the measurement of the distance between the pump chamber and the oil bowl, the measurement of the distance between the top surface of the rotor and the seam surface of the pump cover, and the measured value Records are stored in a database and data processing takes place in the background to automatically select the appropriate gasket for the piston pump assembly. Similarly, the system can also be replicated and promoted in the assembly of reducers, engines, pumps, gearboxes, etc., to measure the installation dimensions of products and guide assembly.

[0056] The automatic measurement and matching system of the present invention specifically includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com