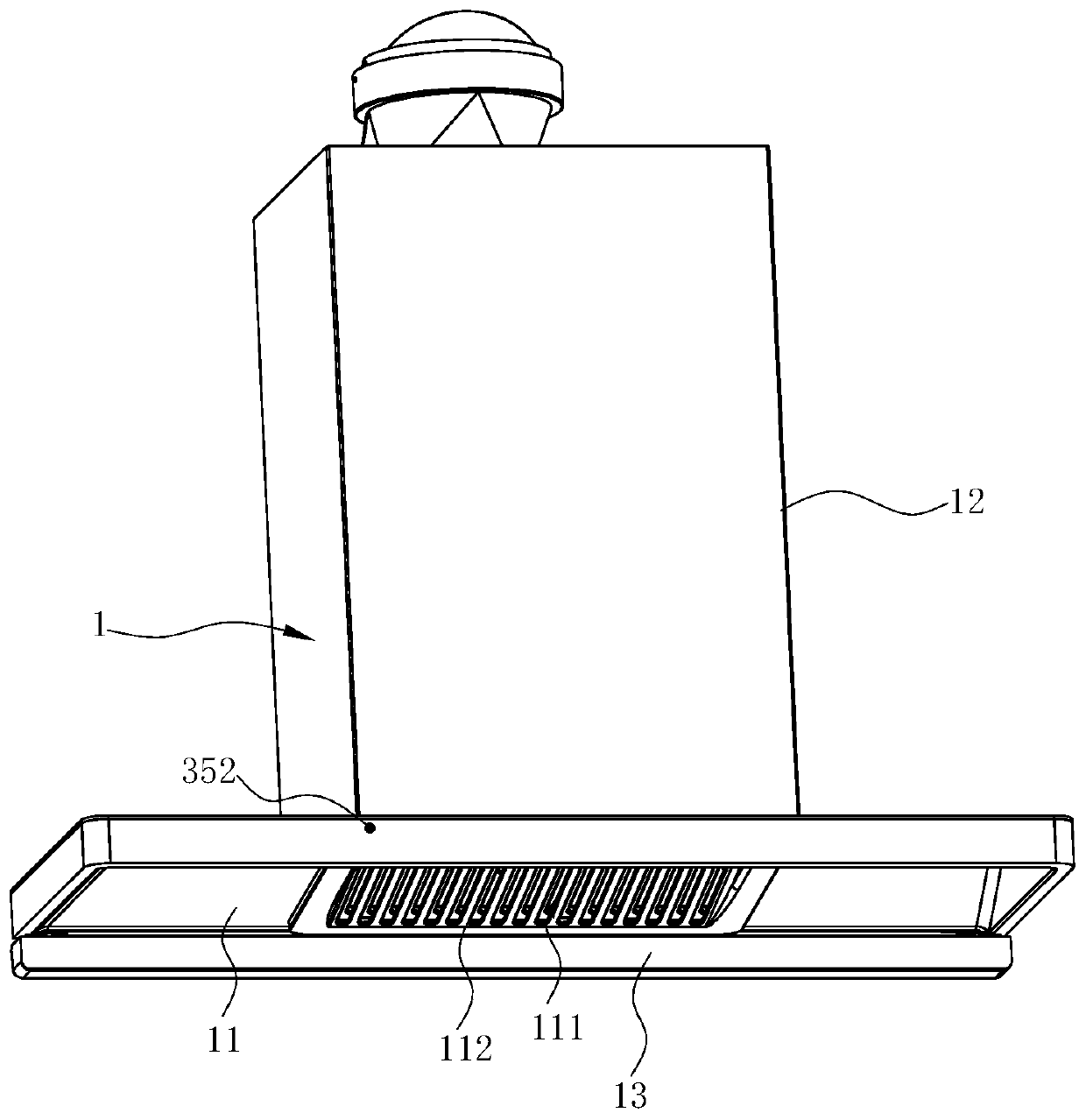

Extractor hood

A technology of range hood and fan rack, applied in the direction of removing range hood, household stove/stove, heating method, etc., can solve the problems of reducing the delicacy of the whole machine and increasing the difficulty of cleaning for users, so as to prolong the service life and avoid accidents. Drop, meet the effect of oil circuit and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

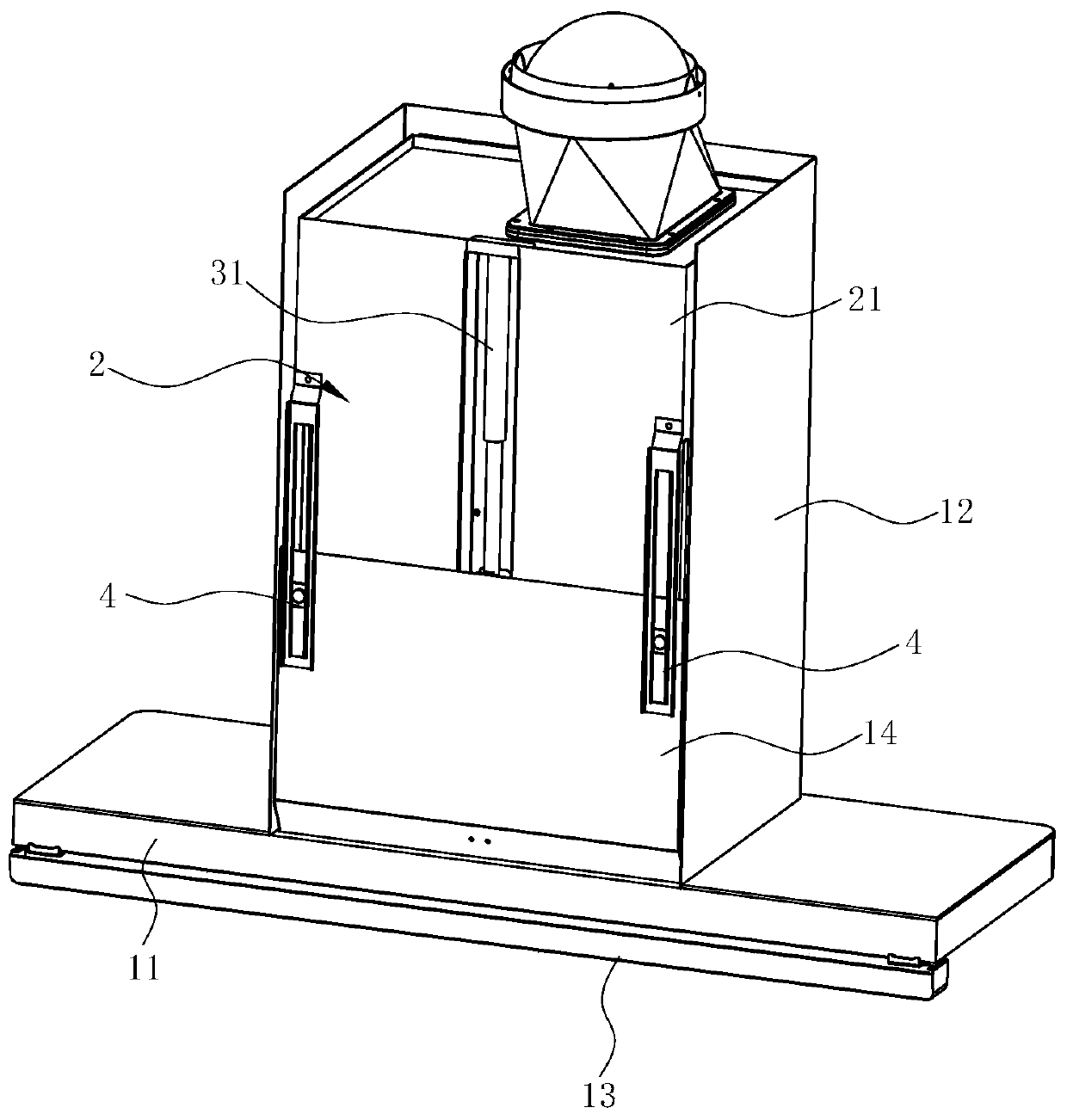

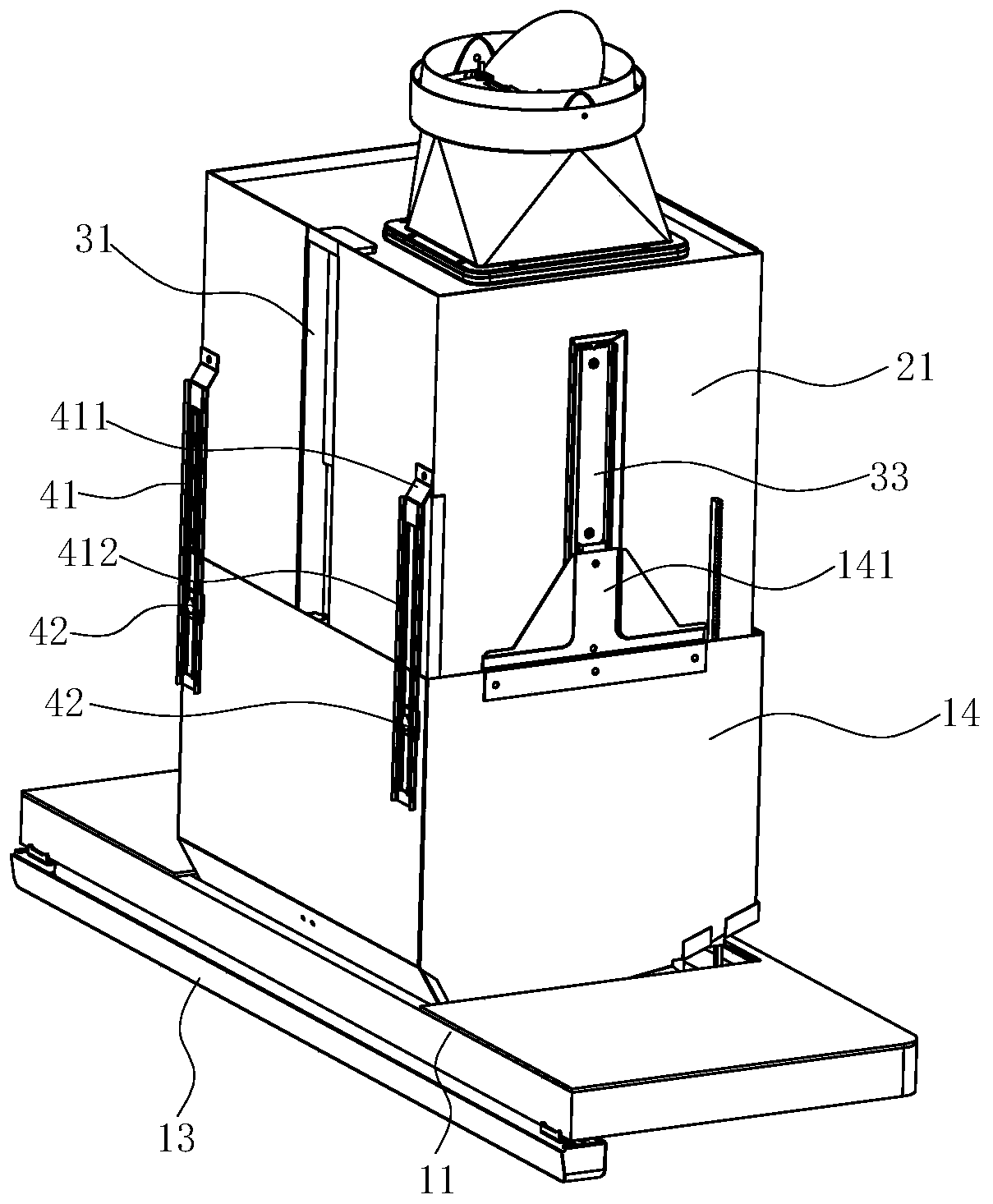

[0051] see image 3 , Figure 4 , Figure 7 and Figure 8 , the range hood also includes a movement mechanism for driving the movable part 1 to move up and down relative to the fixed part 2 , which is a manual movement mechanism, including a balance device 31 , a transmission mechanism 32 and a guide mechanism 33 . Wherein, the balancing device 31 is preferably a pneumatic spring, which is arranged on the rear side of the fan frame 21 and extends in the longitudinal direction. The upper end of the housing of the pneumatic spring is connected and fixed with the fan frame 21, and the telescopic rod 311 of the pneumatic spring can be retracted upward or extended downward. The transmission mechanism 32 includes a sliding block 322 , which is arranged on the telescopic rod 311 of the pneumatic spring, preferably at the end of the telescopic rod 311 , and the sliding block 322 is also connected and fixed with the moving frame 14 . When the user pushes the movable part 1, such as...

Embodiment 2

[0065] see Figure 18 and Figure 19 , the difference from the above-mentioned first embodiment is that the balance device 31 and the transmission mechanism 32 of the motion mechanism are different. In this embodiment, the balance device 31 is a damper composed of coil springs, and the transmission mechanism 32 includes a rotating set on the balance device 31. The gear 323 on the central axis of the fan frame 323, the rack 324 meshing with the gear 323, the first link 325, the second link 326, the first chute 327 arranged on the rear side of the fan frame 21 and the rear of the moving frame 14 The second chute 328 on the side. The first chute 327 is preferably close to the upper part of the rear side of the fan frame 21 , and the second chute 328 is preferably close to the upper part of the rear side of the moving frame 14 . Both the first chute 327 and the second chute 328 extend in the left-right direction and are parallel to each other, preferably, they are both horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com