Compact hybrid drive wind generating set gearbox transmission structure

A wind turbine, hybrid drive technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problem of increasing the speed ratio limit of the gearbox, and achieve the effect of reducing the bending bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

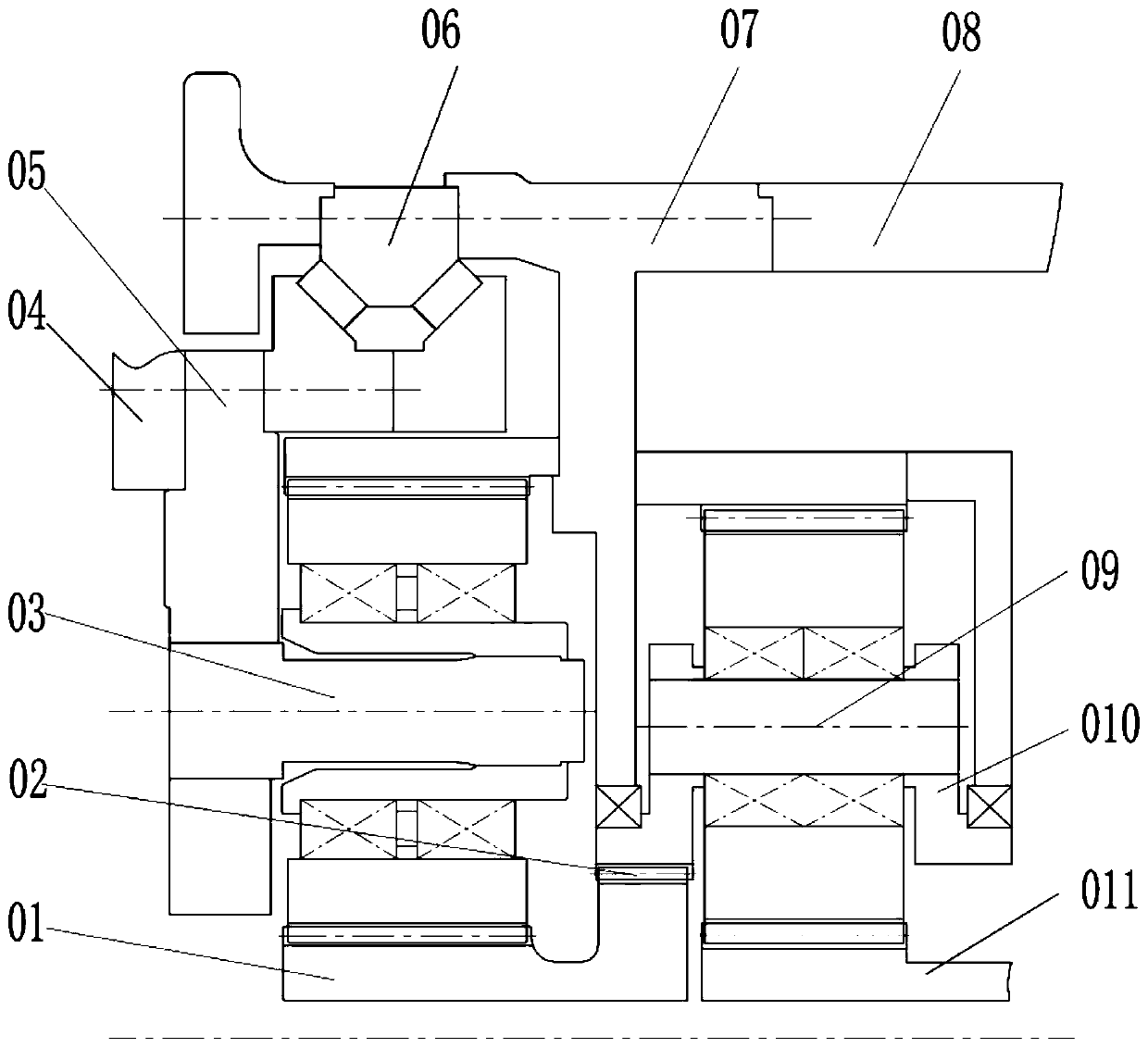

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

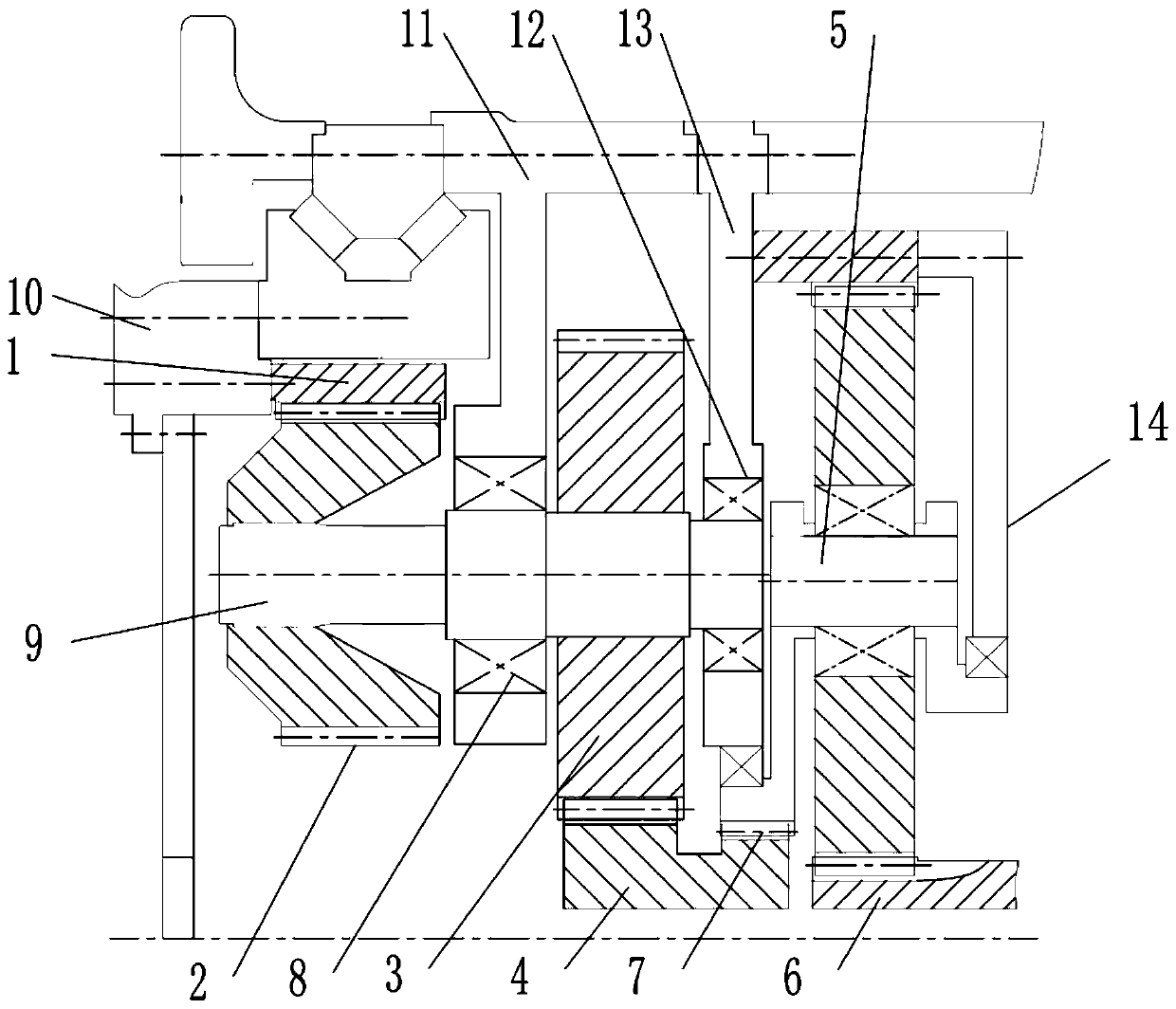

[0015] see figure 2 As shown, the gearbox transmission structure of the compact hybrid drive wind power generator set provided by this embodiment includes a first-stage planetary gear transmission system, a second-stage planetary gear transmission system and a third-stage planetary gear transmission system.

[0016] The first-stage planetary gear transmission system is a fixed-shaft internal meshing transmission system, the power is input by its inner ring gear 1, and then output by n branches through its n external gears 2, n=3,4,5..., The n external gears 2 are evenly distributed in the inner ring gear 1, and mesh with the inner ring gear 1 respectively to distribute the power equally. Installed on the cantilever end of a transmission shaft 9, the transmission shaft 9 is supported on the gear box body 11 and the bearing seat plate 13 through the first bearing 8 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com