Copper nano-electrode with high-index crystal face and preparation method and application thereof

A high-index crystal surface and copper nanotechnology, which is applied in nanotechnology, electrodes, nanotechnology, etc. for materials and surface science, can solve the problems of difficulty in suppressing side reactions and low product selectivity, and facilitate the promotion of industrialization. The preparation method is simple, and the effect of high-index crystal plane stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Copper nanowire electrode materials with high-index crystal faces were prepared by the following steps:

[0045] A. prepare reaction solution, prepare the copper sulfate solution of 0.1mol / L, the sodium hydroxide solution of 15mol / L and the mass concentration be the hydrazine hydrate solution of 35%, and the potassium chloride solution of 1mol / L;

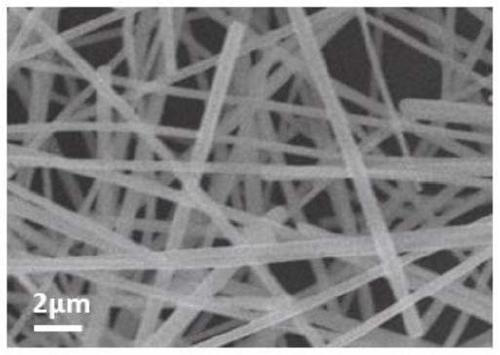

[0046]B. Take 120 mL of 15 mol / L sodium hydroxide solution in a three-necked flask, add 6 mL of 0.1 mol / L copper sulfate solution under stirring, and after ultrasonication for five minutes, add 760 μL of ethylenediamine under stirring conditions and use an oil bath Preheat, when the temperature rises to 70 degrees Celsius, add 60 μL of hydrazine solution with a mass concentration of 35% under stirring, continue stirring for 3 minutes, turn off the stirring, keep the reaction temperature at 70 degrees Celsius, and react for 2 hours to obtain copper nanowires Dispersions;

[0047] C. Uniformly disperse the copper nanowire disp...

Embodiment 2

[0066] Using the copper nanowire electrode material prepared in Example 1, a potassium chloride solution was used as the electrolyte to carry out related tests on electrochemical reduction of carbon dioxide.

[0067] The test system adopts a three-electrode test system, wherein the working electrode is the copper nanowire electrode material prepared in Example 1, the counter electrode is a carbon rod electrode, and the reference electrode is a silver silver chloride electrode. The test conditions are: the electrolyte is a 1mol / L potassium chloride solution, and carbon dioxide gas is introduced into the electrolyte at a rate of 20 ml / min for 30 minutes before the test starts to saturate the electrolyte, and then Under the conditions of normal temperature and pressure plus stirring, the faraday efficiency and current density of the electrode were tested, and at different potentials, the constant potential scanning test method was used to measure the faraday efficiency of various ...

Embodiment 3

[0085] The copper nanowire electrode material with a high-index crystal plane was prepared according to the method described in Example 1. The difference from Example 1 is only that the treatment time of square wave potential is 30 minutes, 60 minutes, and 120 minutes, respectively. Finally, three copper nanowire electrode materials with high-index crystal planes were obtained.

[0086] The three copper nanowire electrode materials obtained above were characterized.

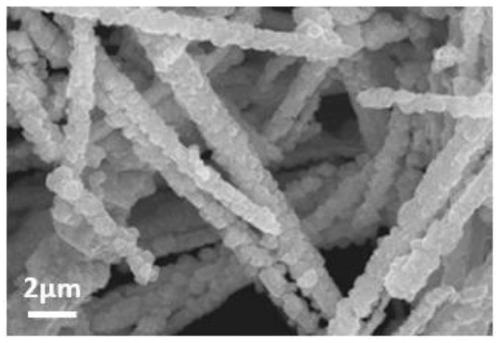

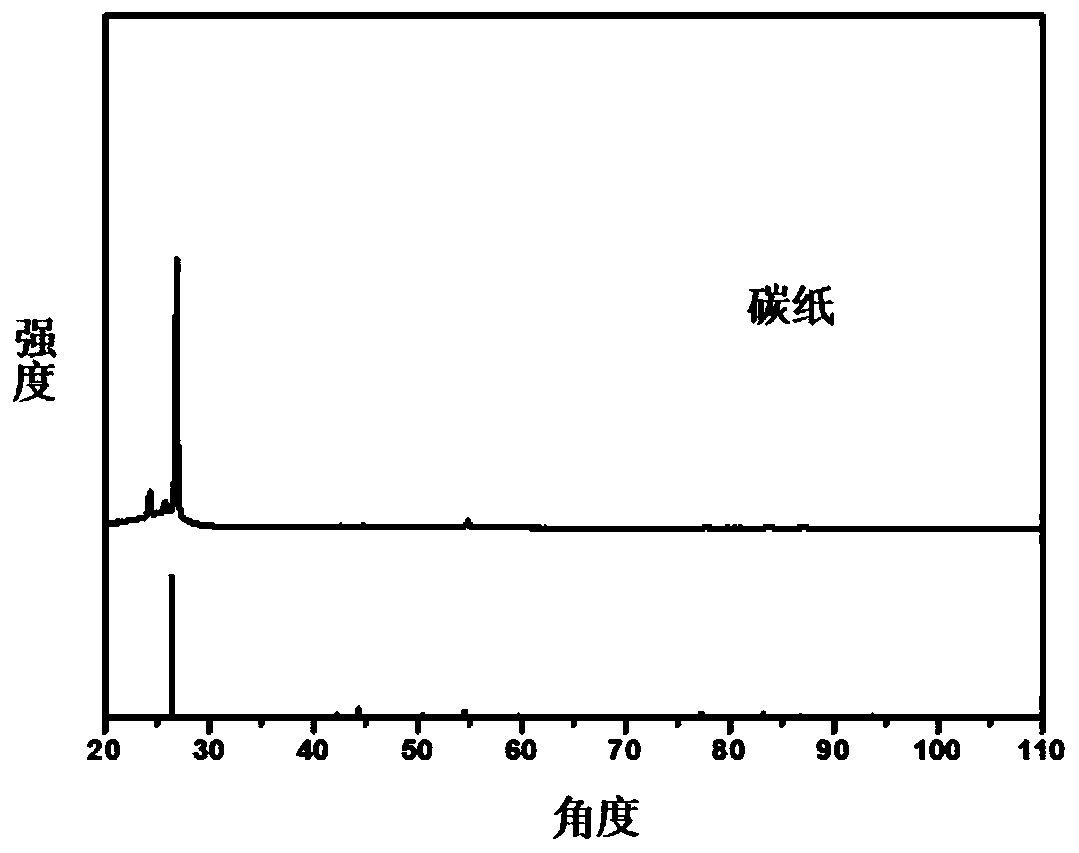

[0087] Figure 8-Figure 10 It is the scanning electron microscope image of the high-index crystal surface copper nanowire electrode material obtained after square wave treatment for 30 minutes, 60 minutes and 120 minutes.

[0088] Figure 8-Figure 10 It can be seen that with the increase of the square wave treatment time, the copper nanowires gradually become rough from the smooth surface at the beginning, until the treatment time is 90 minutes, the surface of the copper nanowires appears a step-like morphology...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com