Paperboard waste bottom material receiving mechanism

A waste and cardboard technology, which is applied to the field of the bottom splicing mechanism of cardboard waste, can solve the problems of inconvenient cleaning, difficult cleaning, trouble, etc., and achieve the effect of convenient dumping and transportation, and convenient waste collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

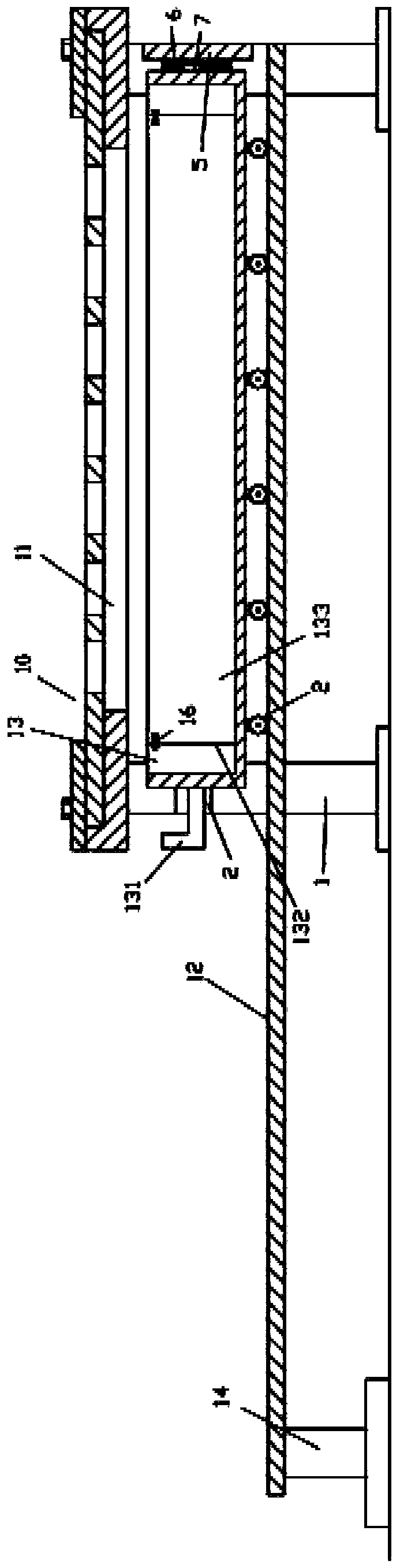

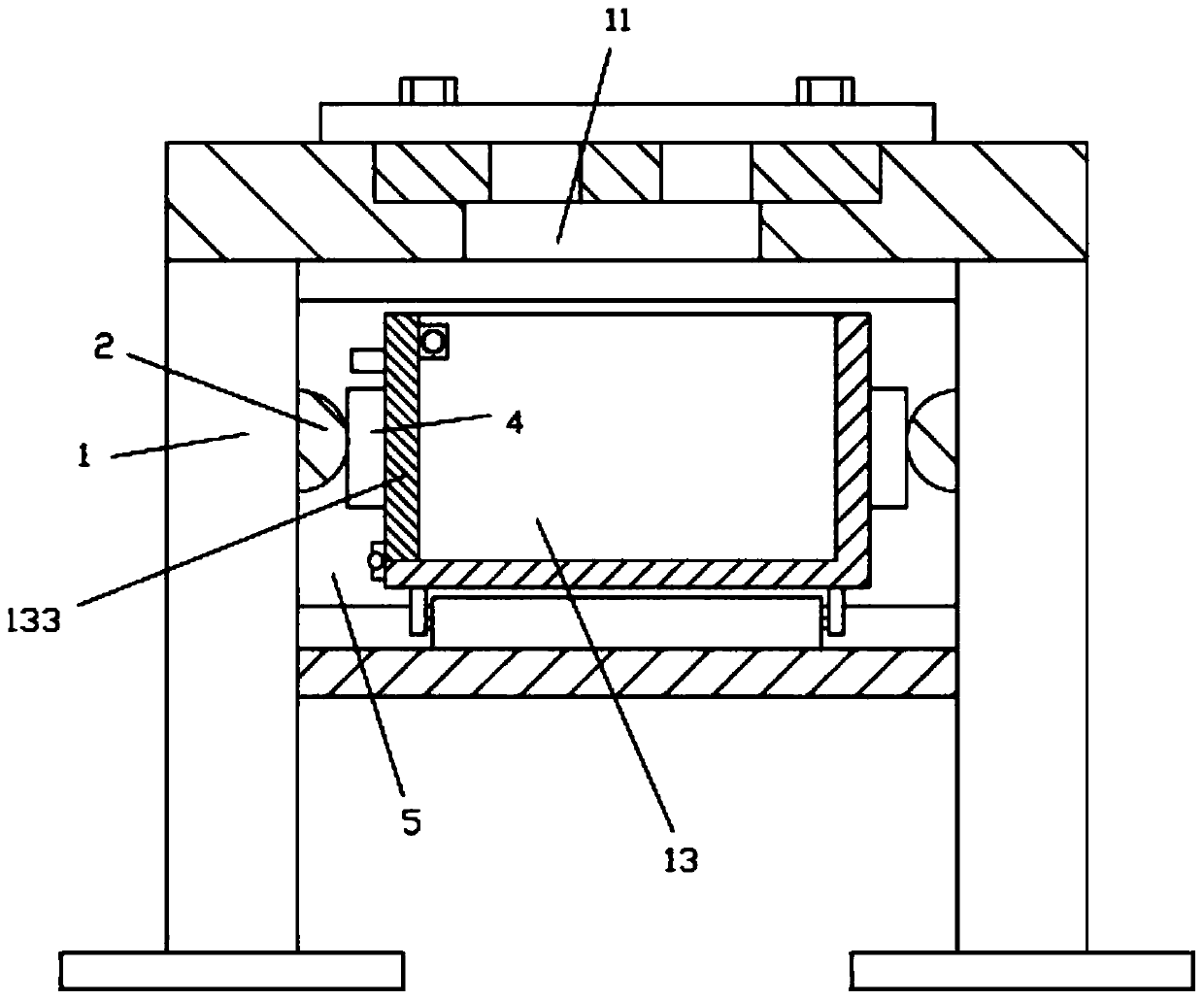

[0020] Examples, see e.g. Figure 1 to Figure 3 As shown, a bottom material receiving mechanism for cardboard waste includes a frame 10, and the middle part of the top surface of the top plate of the frame 10 has a processing blanking channel 11;

[0021] The bottom of the top plate of the frame 10 is provided with a horizontal horizontal plate 12, and the top surface of the horizontal horizontal plate 12 is placed with a waste material receiving tank body 13, and the waste material receiving tank body 13 is directly below the processing blanking channel 11;

[0022] The left end of described transverse horizontal plate 12 stretches out the left side wall of frame 10, and the left end bottom surface of transverse horizontal plate 12 is fixed with connecting support leg 14, and the bottom surface of connecting support leg 14 is pressed against the ground.

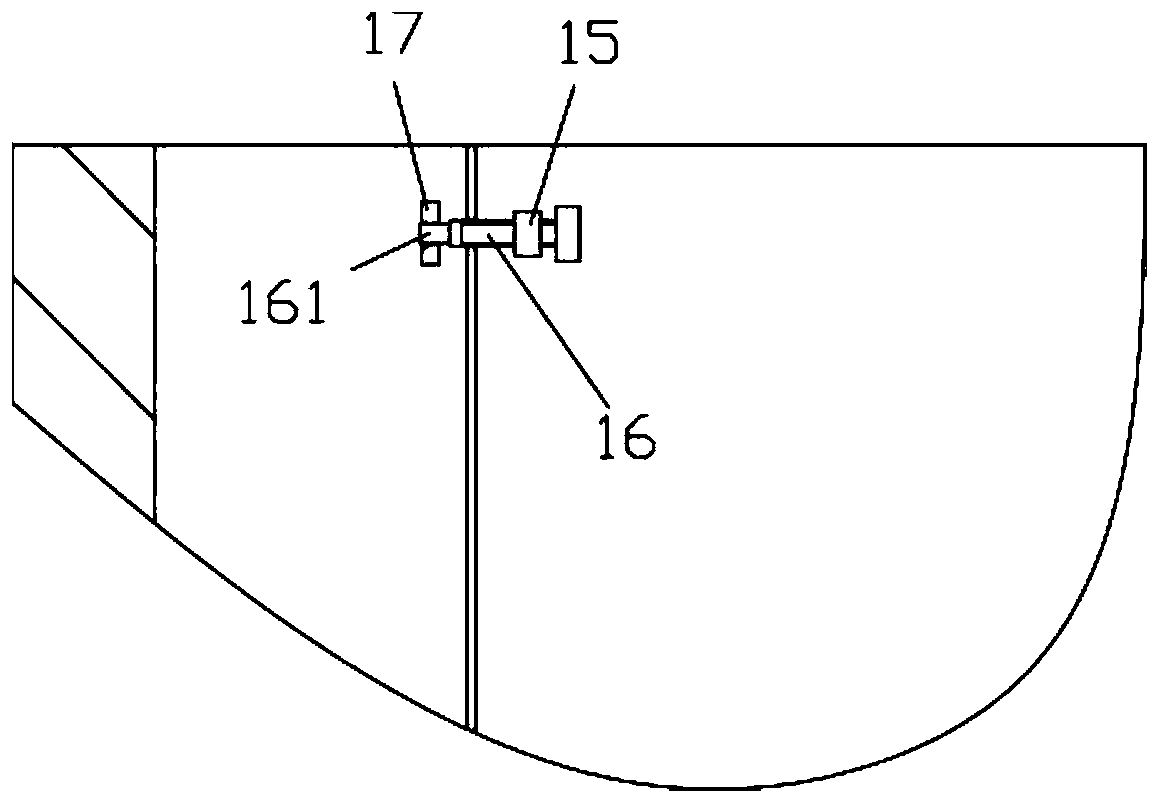

[0023] Further, the front wall and the rear wall of the middle and rear of the transverse horizontal plate 12

[0024] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com