Recyclable packing box for express service

A packaging box and bottom plate technology, applied in the field of recyclable express packaging boxes, can solve problems such as environmental pollution, waste of resources, and reduction in the number of express delivery items, and achieve the effects of reducing garbage and environmental pollution, avoiding resource waste, and reducing volume waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

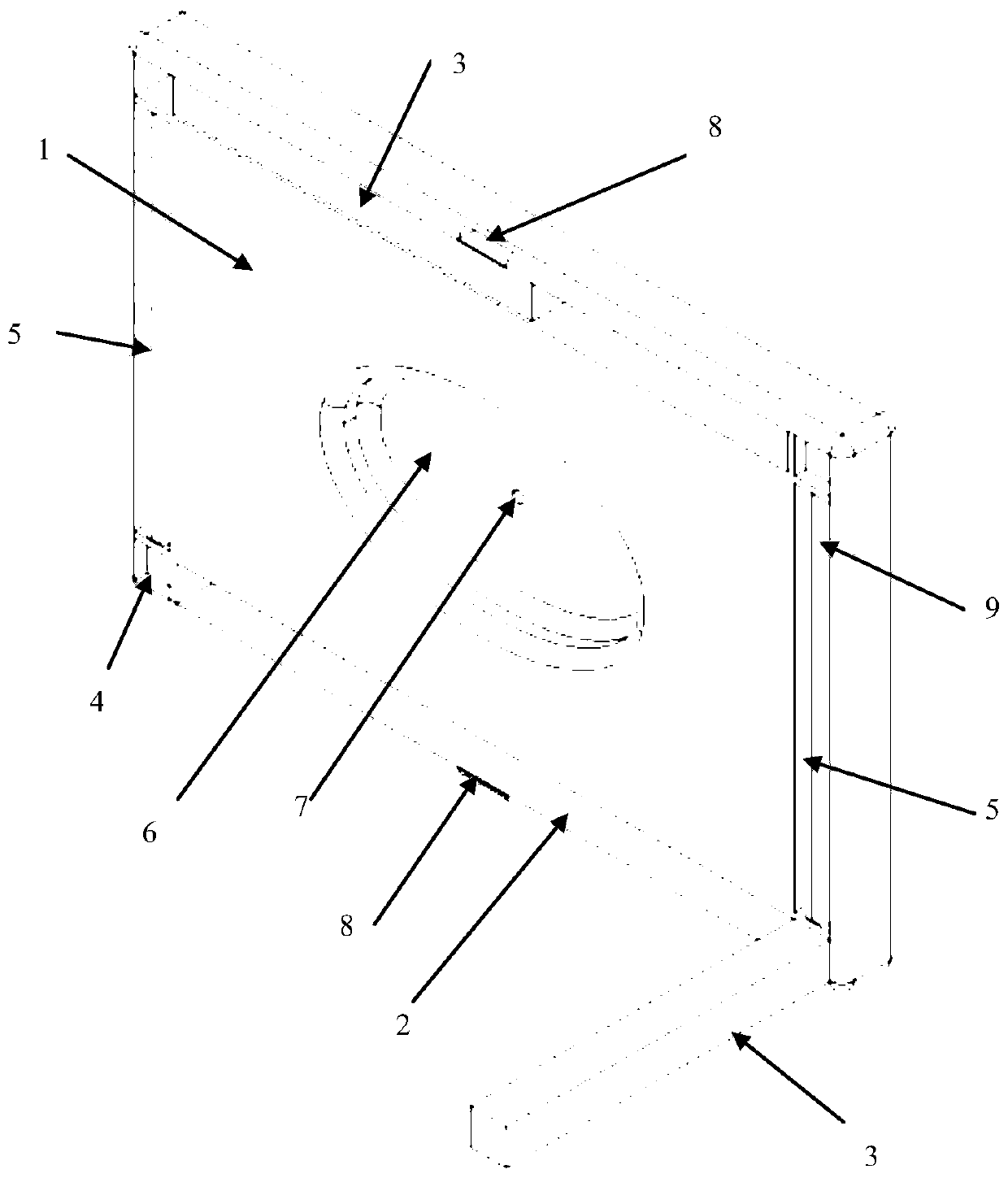

[0021] Embodiment 1, a recyclable express packaging box, including two bottom plates 1, a series of sizes can be designed for the bottom plates with reference to "GB / T4892-2008 Packaging Dimension Series", the module size of the transport package is 600mm*400mm, this According to the actual investigation results, the plane size of the invention can be obtained by multiplying or dividing the packaging module size by an integer to obtain a series of reasonable sizes. The dimensions of other components mentioned in the first embodiment are all defaulted to the corresponding size of the module size. The thickness of each bottom plate in the first embodiment is 50mm. Each base plate is in the shape of a rectangle, and the two base plates 1 include an upper base plate and a lower base plate opposite to the upper base plate.

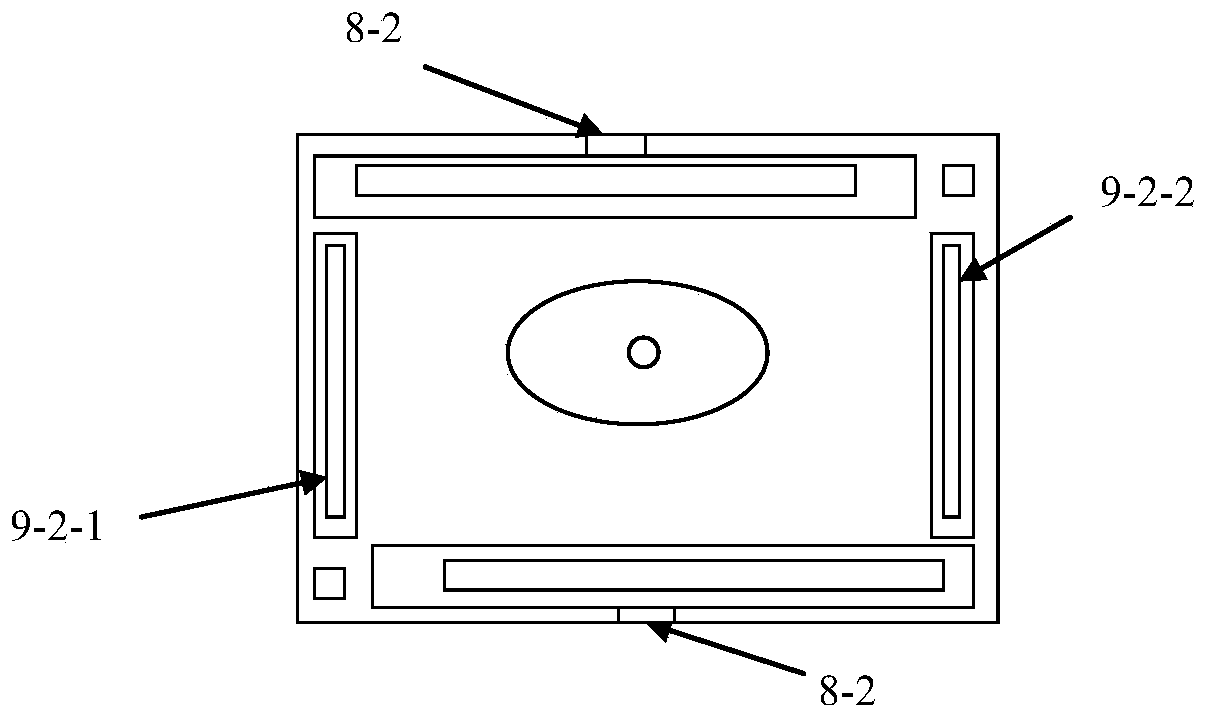

[0022] Such as figure 1 As shown, both the upper base plate and the lower base plate include a first structure and a second structure, and the first structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com