Passenger car water filling nozzle sealing dustproof device

A dust-proof device and water injection port technology, which is applied to locomotives, transportation and packaging, railway car body parts, etc., can solve problems such as potential safety hazards, forgetting to close the dust cover, and large air flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

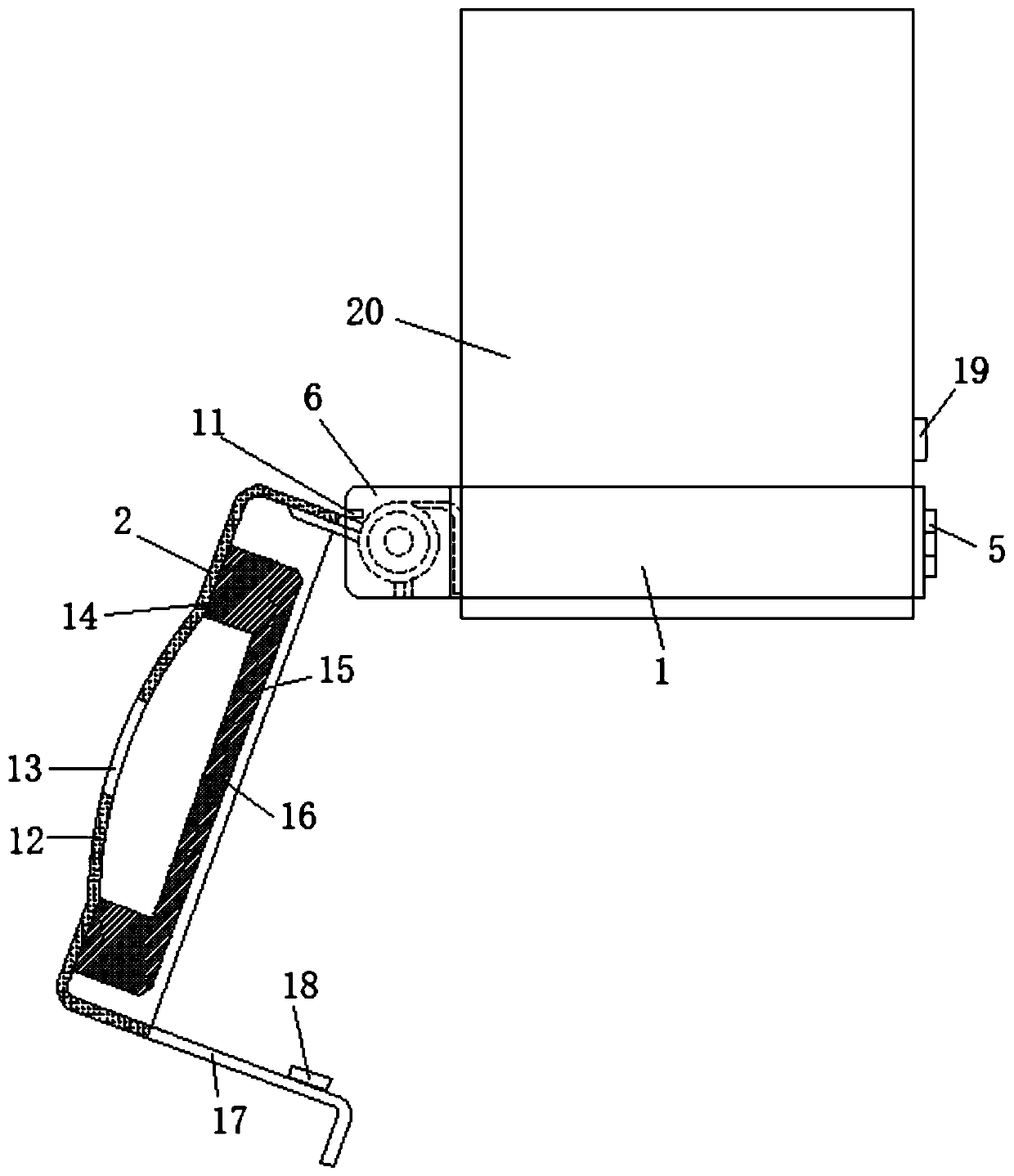

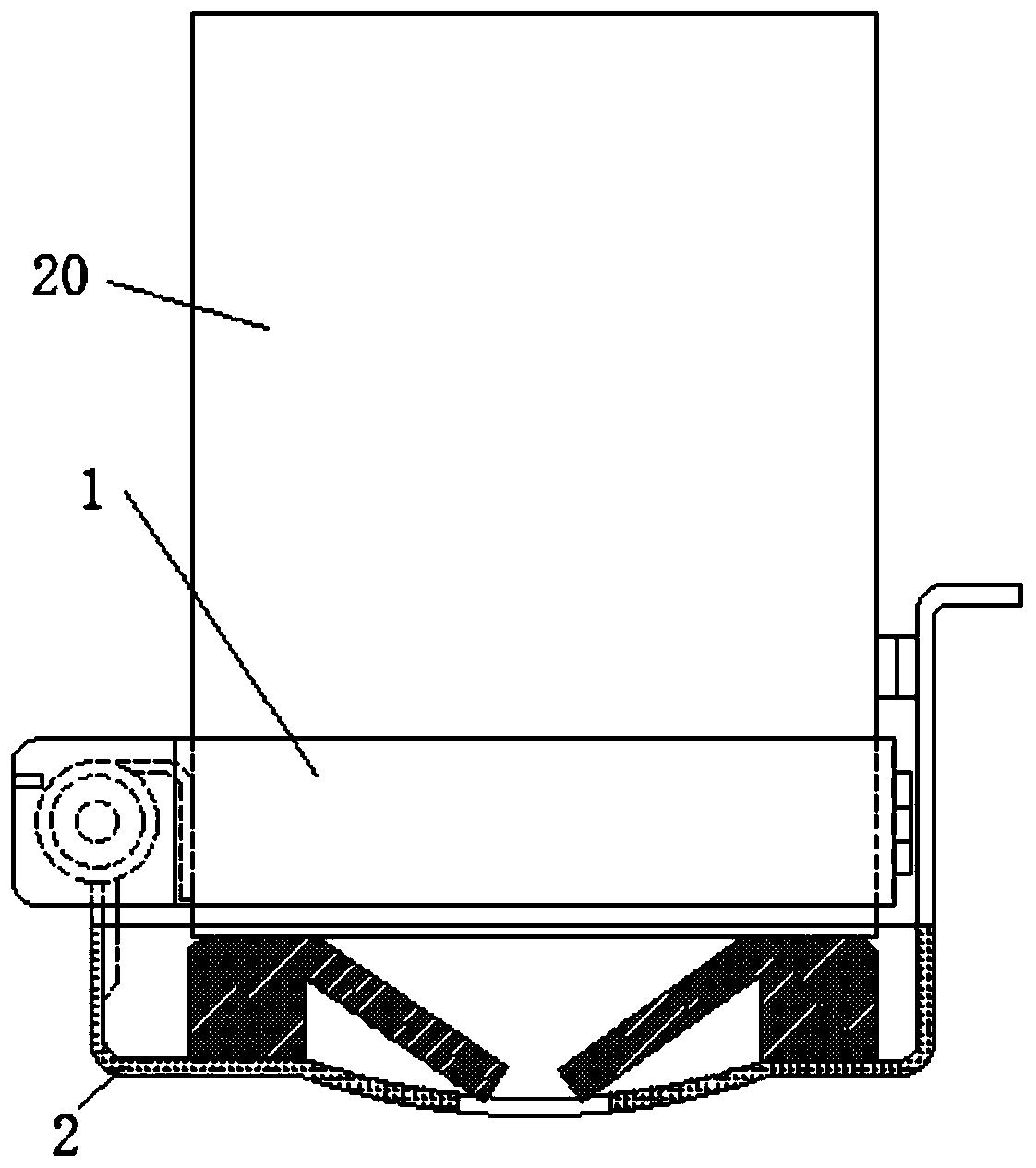

[0025] A passenger car water injection port sealing and dustproof device, including a hoop set on the water injection pipe, an openable cover plate arranged at the water injection port and connected to the hoop through a hinge reset mechanism;

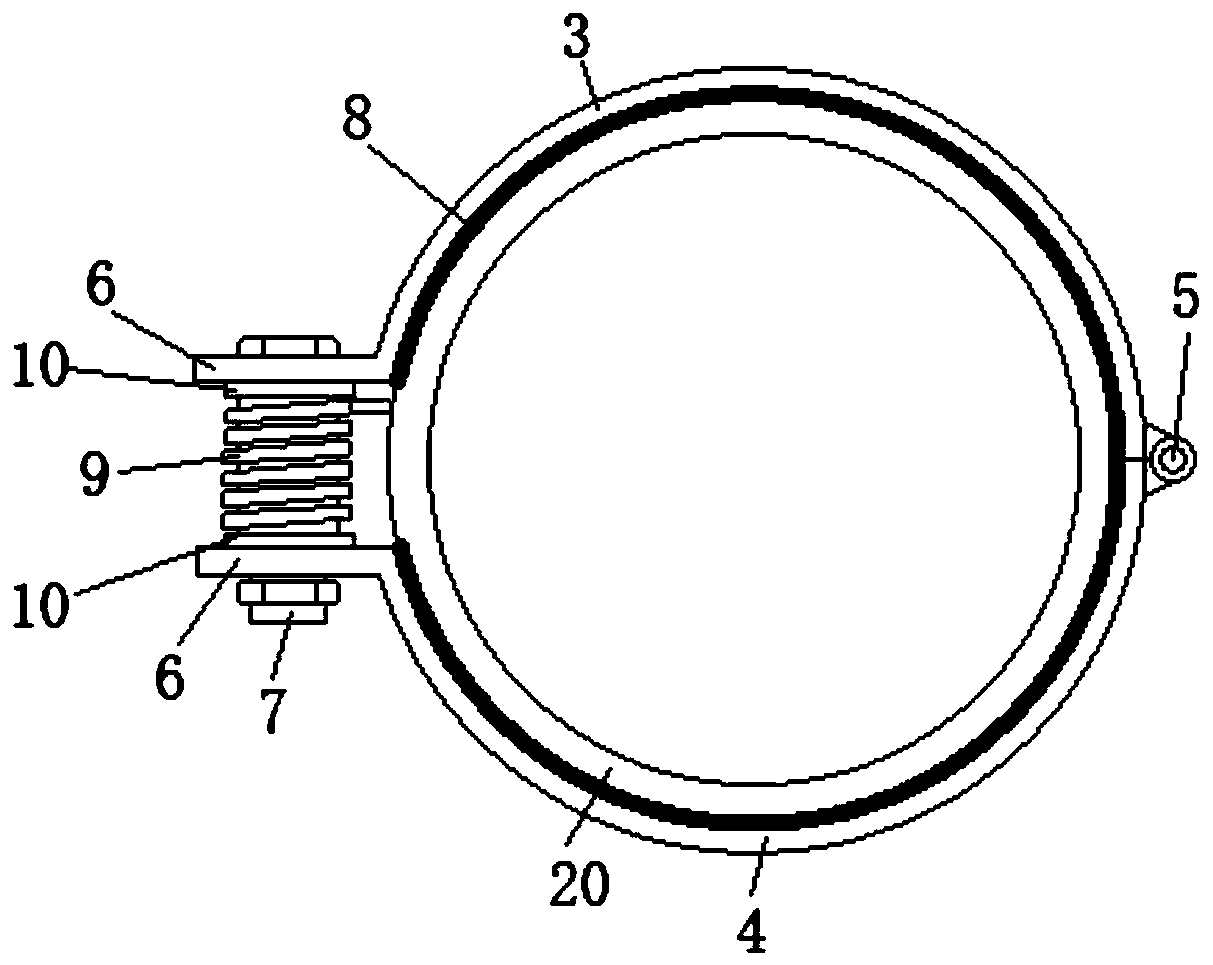

[0026] The hoop includes a first arc-shaped connecting plate and a second arc-shaped connecting plate whose inner wall is attached to the water injection pipe. One end of the first arc-shaped connecting plate and the second arc-shaped connecting plate are hingedly connected by a hinge. The other ends of the arc-shaped connecting plate and the second arc-shaped connecting plate are respectively provided with connecting flanges, and the two connecting flanges are connected by bolts and nuts, which is convenient for later installation and disassembly of the cover plate. The first arc-shaped connecting plate and The inner wall of the second arc-shaped connecting plate is provided with an anti-slip gasket to improve the anti-slip property of...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 lies in that the inner walls of the first arc-shaped connecting plate and the second arc-shaped connecting plate are provided with protrusions for positioning, and the outer wall of the water injection pipe is provided with protrusions that match the protrusions. The groove further improves the anti-slip and stability of the hoop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com