Electric field auxiliary deep drawing device for stepped part

An electric field-assisted, stepped technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large sheet sliding, unclear ejection mechanism, and inability to form stepped parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail:

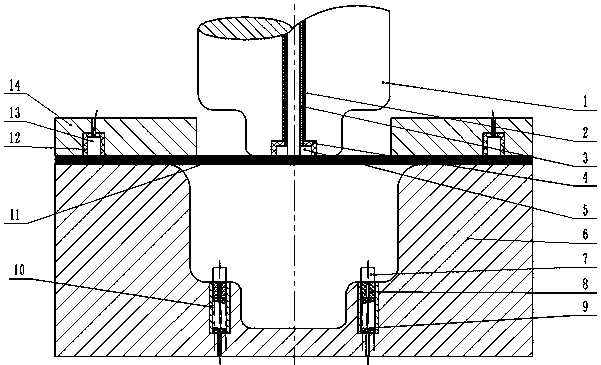

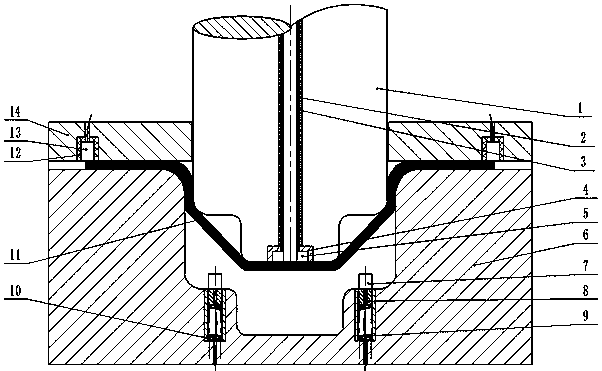

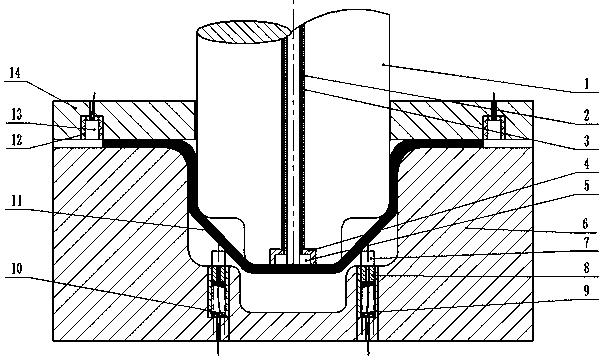

[0027] The present invention is an electric field assisted deep drawing device for stepped shaped parts, comprising a punch 1 fixed on the upper die base and the upper die base for insulation treatment, a blank holder 14 fixed on the upper die base and outside the punch die, and a lower The die 6 with the inner hole on the upper part of the mold base is driven by the press to make the punch 1 and the blank holder 14 go down until the blank holder 14 presses the blank 11, and the punch 1 contacts the blank 11. For stretching work, there is a through hole in the middle of the punch 1, and an insulating tube 2 is arranged in the through hole, and a energizing tube 3 is arranged in the insulating tube 2, and the energizing tube 3 is connected to the live wire of the power supply, and the energizing tube 3 is connected to the lower end of the punch 1. The head electrode 5 is in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com