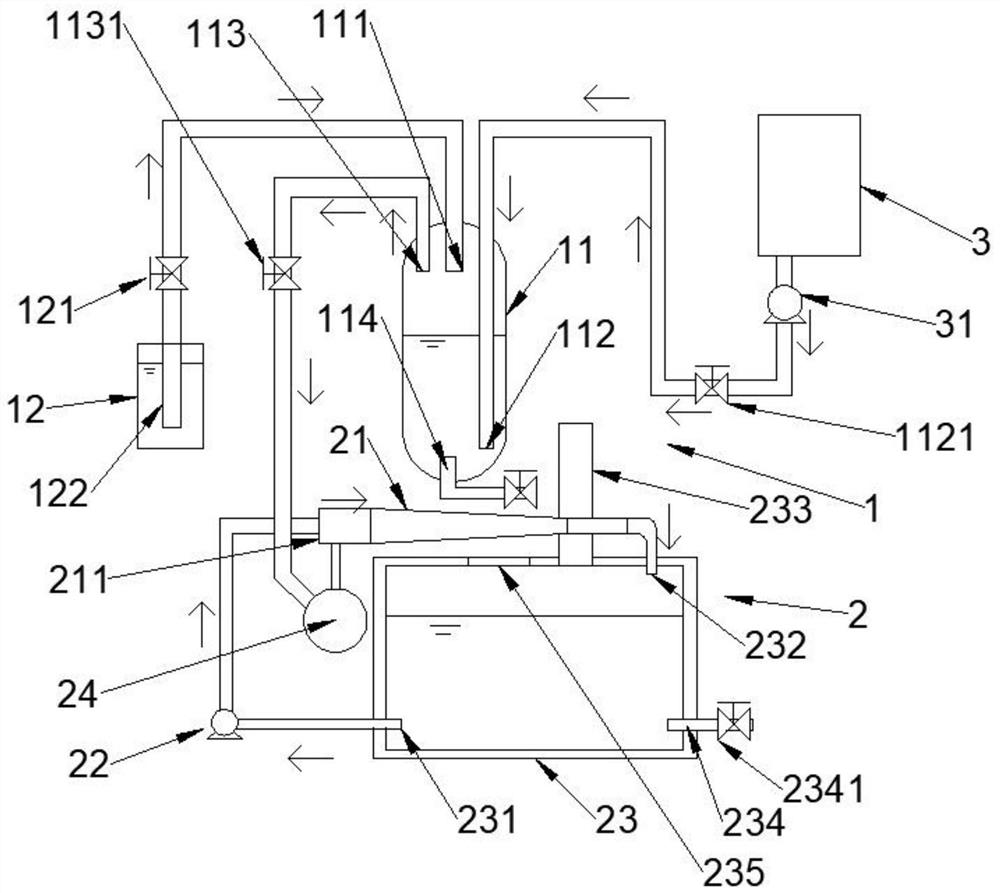

A kind of exhaust gas treatment system and method based on Venturi effect

A technology for waste gas treatment and treatment liquid, applied in the field of waste gas treatment system based on Venturi effect, can solve the problems of long treatment time, high investment cost, large floor space, etc., achieve obvious effect, improve treatment efficiency, and reduce operation risk The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

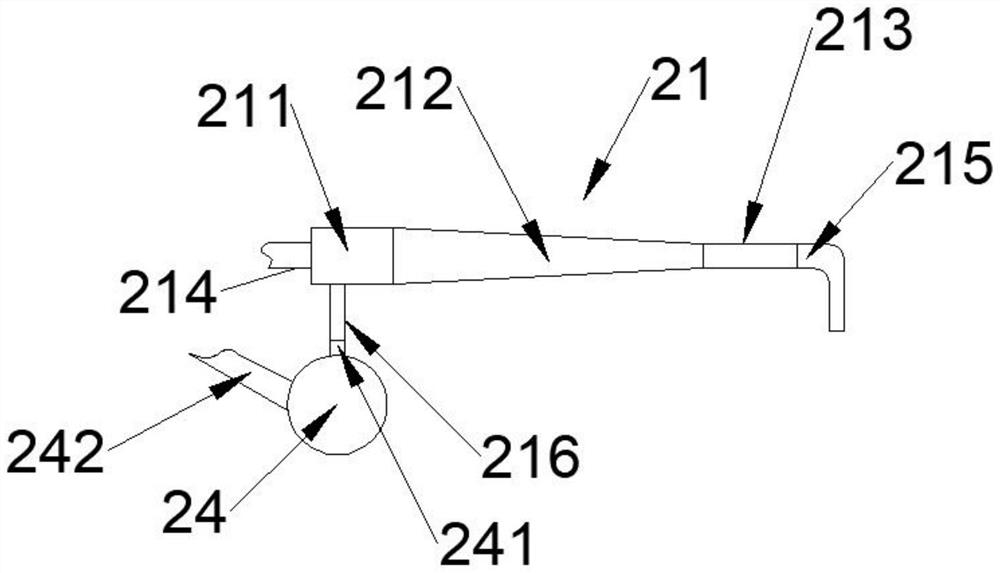

Method used

Image

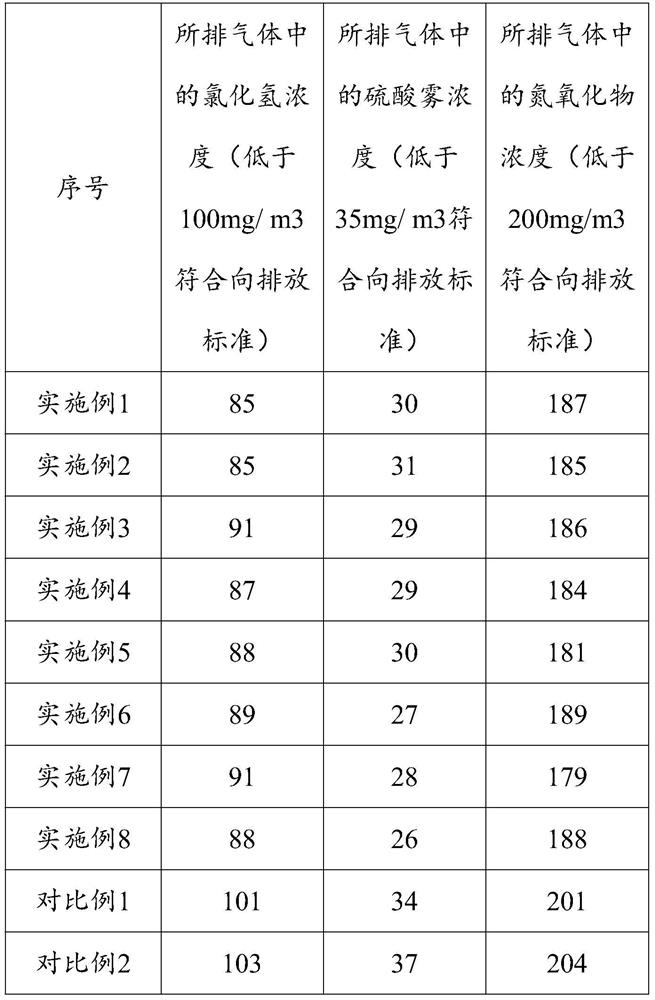

Examples

Embodiment 1

[0030] Step (1): dissolving sodium hydroxide in distilled water, then performing high-speed stirring treatment to complete dissolution, then adding acid mist sedimentation agent, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, and controlling sodium perhydroxide The ratio of the volume of the acid mist precipitation agent to the total volume of the solution is 30% and 5%, respectively, to obtain a first-level treatment solution, wherein the acid mist precipitation agent is sodium carbonate;

[0031] Step (2): dissolving urea peroxide and acid mist absorbent in distilled water, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, then adding acid mist precipitation agent and carrying out high-speed stirring treatment to complete dissolution, statically Set it to cool to room temperature, and control the volume ratio of urea peroxide, acid mist absorbent and ac...

Embodiment 2

[0036] Step (1): dissolving sodium hydroxide in distilled water, then performing high-speed stirring treatment to complete dissolution, then adding acid mist sedimentation agent, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, and controlling sodium perhydroxide The volume of the acid mist precipitation agent accounts for 30% and 5% of the total solution volume, respectively, to obtain a first-level treatment solution, wherein the acid mist precipitation agent is potassium carbonate;

[0037] Step (2): dissolving urea peroxide and acid mist absorbent in distilled water, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, then adding acid mist precipitation agent and carrying out high-speed stirring treatment to complete dissolution, statically Set it to cool to room temperature, and control the volume ratio of urea peroxide, acid mist absorbent and acid mist...

Embodiment 3

[0042] Step (1): dissolving sodium hydroxide in distilled water, then performing high-speed stirring treatment to complete dissolution, then adding acid mist sedimentation agent, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, and controlling sodium perhydroxide The ratio of the volume of the acid mist precipitation agent to the total volume of the solution is 30% and 5%, respectively, to obtain a primary treatment solution, wherein the acid mist precipitation agent is cationic polyacrylamide;

[0043] Step (2): dissolving urea peroxide and acid mist absorbent in distilled water, then carrying out high-speed stirring treatment to complete dissolution, standing to cool to room temperature, then adding acid mist precipitation agent and carrying out high-speed stirring treatment to complete dissolution, statically Set it to cool to room temperature, and control the volume of urea peroxide, acid mist absorbent and acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com