Puncture needle sleeve and puncture needle

A puncture needle and cannula technology, applied in the field of puncture needles, can solve problems such as unclear puncture needles, and achieve the effects of reducing the difficulty and risk of operation, increasing the success rate of puncture, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

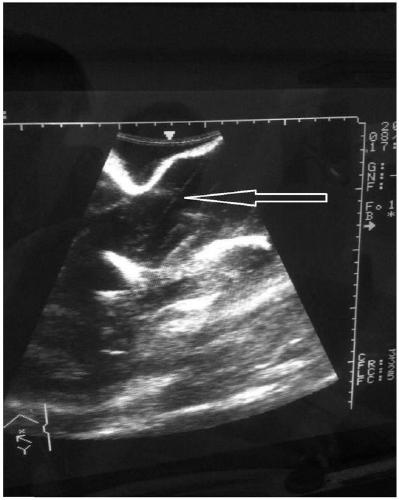

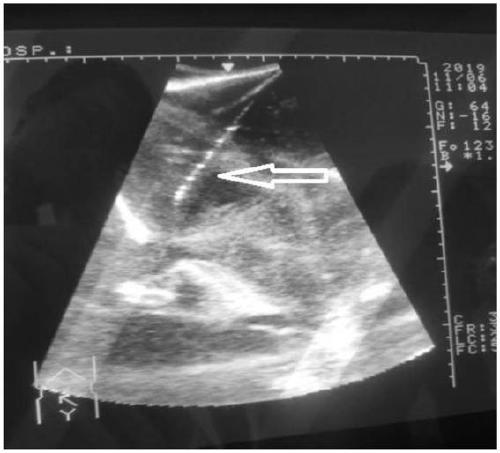

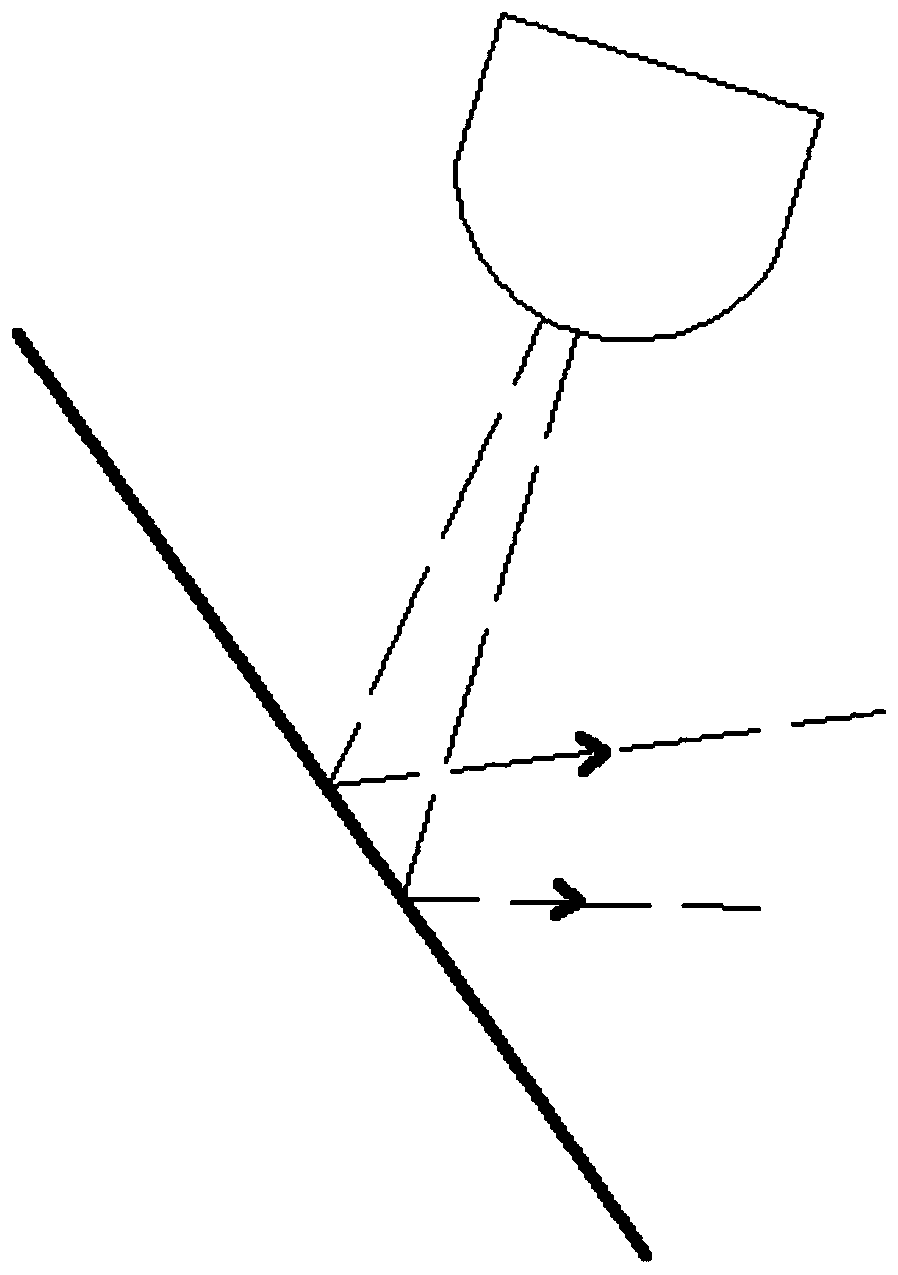

Image

Examples

Embodiment 1

[0041] like Figure 4 As shown, a puncture needle sleeve includes a linear connecting part 1, the radial cross section of the connecting part 1 is circular; the head 2 is integrally formed with one end of the connecting part 1, and is located on the same line On a straight line; the scale line 8 uniformly arranged on the outer periphery of the connecting part 1; the detecting part 4 is arranged on the connecting part 1.

[0042] The head 2 and the connecting portion 1 are on the same straight line, which can facilitate the smooth entry of the puncture cannula. The integral molding of the connecting part 1 and the head 2 is convenient to manufacture. After forming, the surfaces of the connecting part and the head 2 need to be polished to remove surface burrs, which can reduce injuries to patients. The connection part 1 and the head part 2 are made of the same material, titanium steel can be used, and the titanium steel material will not undergo chemical reaction or corrosion u...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the specific design of the detection part 4 is different, and the rest are the same as Embodiment 1.

[0051] Specifically, such as Image 6 As shown, the detection part 4 adopts a square connection plate 6 , the design of the square connection plate 6 is simple, and the imaging effect is good. The arc surface of the connecting part 1 is provided with a connecting groove matched with the connecting plate 6, and the connecting plate 6 is arranged in the connecting groove. And it is integrally formed with the arc surface of the connecting portion 1 . When making, it can be made by one-piece molding. The connection groove of the present invention is not directly set on the arc surface, but adopts the method of leaving or cutting out a square section of the arc-shaped connecting part. When connecting, connect the connecting plate 6 directly to this section. The square connection plate can increase the refle...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that the specific design of the detection part 4 is different, and the rest are the same as Embodiment 1.

[0054] Specifically, such as Figure 7 As shown, the design of the detection part 4 of the present invention adopts an arc-shaped protrusion 7 . The number of arc-shaped protrusions 7 is 13, and the arc-shaped protrusions 7 are arranged on the outer periphery of the connecting portion 1 . The height of the arc-shaped protrusion 7 is about 1 mm. The arrangement form of the arc-shaped protrusions 7 is directly arranged on the surface of the connecting part 1, and the distance between two adjacent arc-shaped protrusions 7 is the same, about 10 mm. Two arc-shaped protrusions 7 are arranged between the scale line 8 near the head 2 on the far right and the head 2, and the distance between the nearest arc-shaped protrusion 7 to the head 2 and the head 2 is 2.5 mm. The distance from the second arc-shaped protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com