Working electrolyte of lead aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as insufficient power supply, failure to perform normally, and large voltage fluctuation range, and achieve freedom from hydration reactions, high withstand voltage, The effect of increasing the flash voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

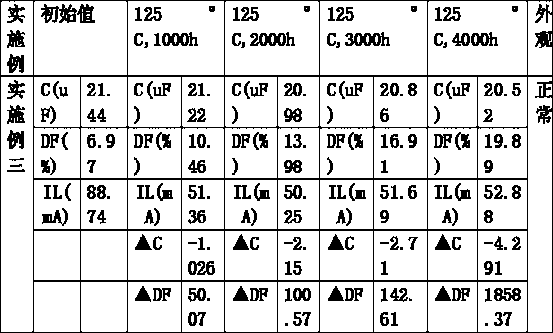

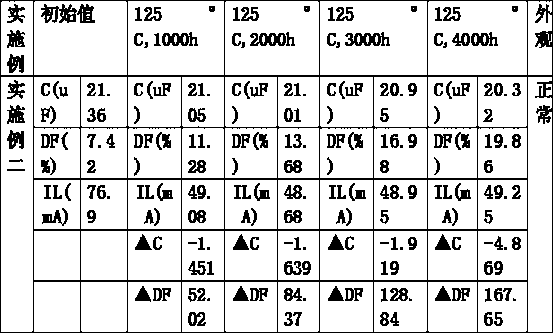

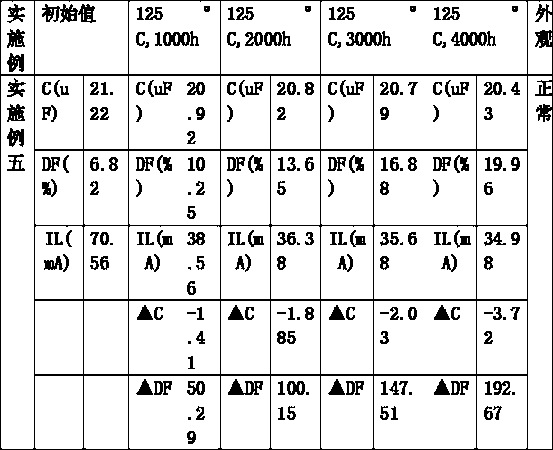

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

[0020] A working electrolyte for leaded aluminum electrolytic capacitors, the working electrolyte is composed of the following raw materials in mass percentage: solvent one: 30-50%, solvent two: 10-20%, solute one: 6-9%, solute two: 2 -4%, antifouling agent: 1-3%, additive: 5-20%, pressure-resistant enhancer: 8-20%, wherein the weight of solute 1 accounts for 10-20% of the weight of solvent 1, and the weight of solute 2 accounts for all 10-20% of the weight of solvent two, the mass ratio of solvent one to solvent two is 7-8:3-2, solvent one is ethylene glycol, and solvent two is gamma-butyrolactone.

[0021] Solute 1 is one or both of 1,5-dodecanedioic acid and its ammonium salt, 1,6-dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com