Extruded composite smooth aluminum sleeve cable production equipment and a production method

A technology for producing equipment and aluminum sleeves, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc. It can solve the problems of bowing, wrinkling, and uneven coating of hot melt adhesives, etc., and achieves small outer diameter and elastic modulus. Big, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

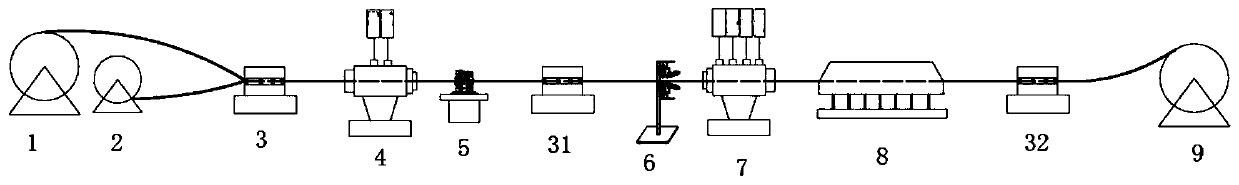

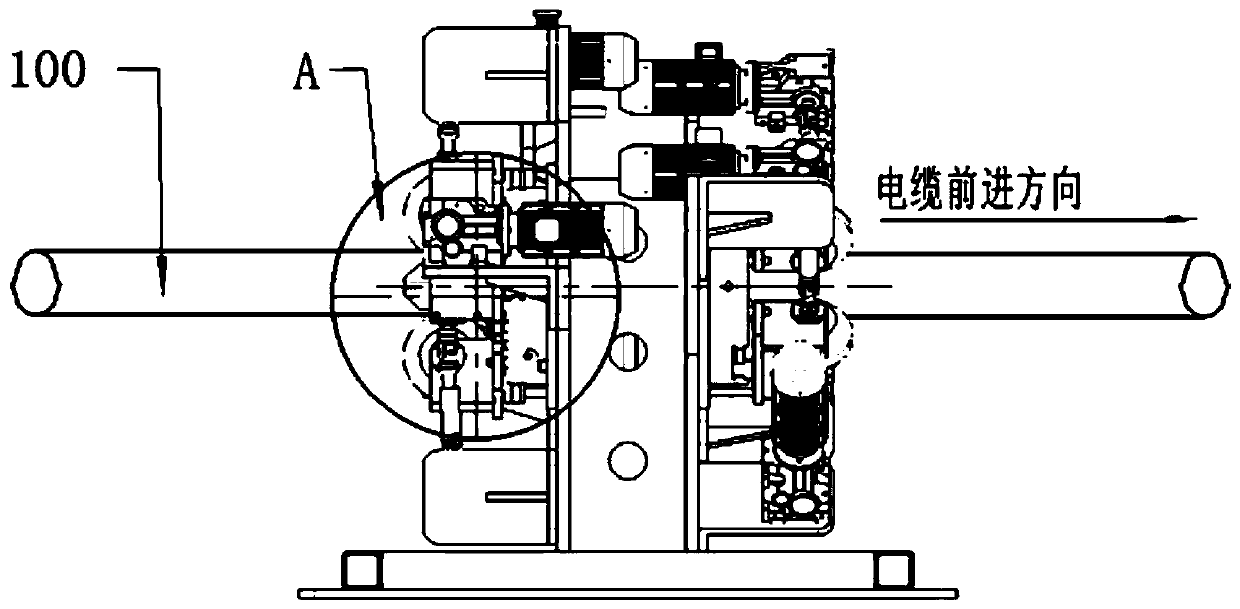

[0039] refer to figure 1 As shown, an extruded composite smooth aluminum sheathed cable production equipment includes a cable pay-off stand 1, an aluminum rod pay-off stand 2, a front traction device 3, an extruded aluminum sheath device 4, a wheel-type reducing device 5, a middle traction Device 31, preheating device 6, multi-layer co-extrusion device 7, cooling water tank 8, rear traction device 32, cable take-up device 9.

[0040]Wherein, a cable core disc is installed on the cable pay-off frame 1 for releasing the cable core. An aluminum rod disc is installed on the aluminum rod pay-off frame 2 for releasing the aluminum rod. The aluminum sheath extruding device 4 continuously extrudes the aluminum sheath so that the aluminum sheath covers the core of the high-voltage cable. The wheel-type reducing device 5 shrinks the aluminum sheath to the outer diameter of the process design, so that the extruded aluminum sheath is wrapped on the surface of the cable core as a whole. ...

Embodiment 2

[0050] A production method of an extruded composite smooth aluminum sheath cable is produced by using the production equipment for an extruded composite smooth aluminum sheath cable described in Embodiment 1, and its production process is as follows:

[0051] S1: Release the cable core from the cable core reel on the cable pay-off frame, and release the aluminum rod from the aluminum rod reel on the aluminum rod pay-off rack, then continuously extrude the aluminum sleeve through the aluminum sleeve extrusion device, so that the aluminum sleeve is covered on the high-voltage cable. Outside the core;

[0052] S2: The wheel-type reducing device shrinks the aluminum sheath to the outer diameter of the process design, so that the extruded aluminum sheath is wrapped on the surface of the cable core as a whole;

[0053] S3: heating the extruded aluminum sleeve through the preheating device;

[0054] S4: Laminate the aluminum sheath with hot melt adhesive, PE sheath, PVC sheath and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com