Induced draft fan inlet flue gas flow measuring device and method

A technology of flue gas flow and measurement device, which is applied to the volume/mass flow generated by mechanical effects, the detection of fluid flow by measuring differential pressure, the electrochemical variables of materials, etc. Simple method, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

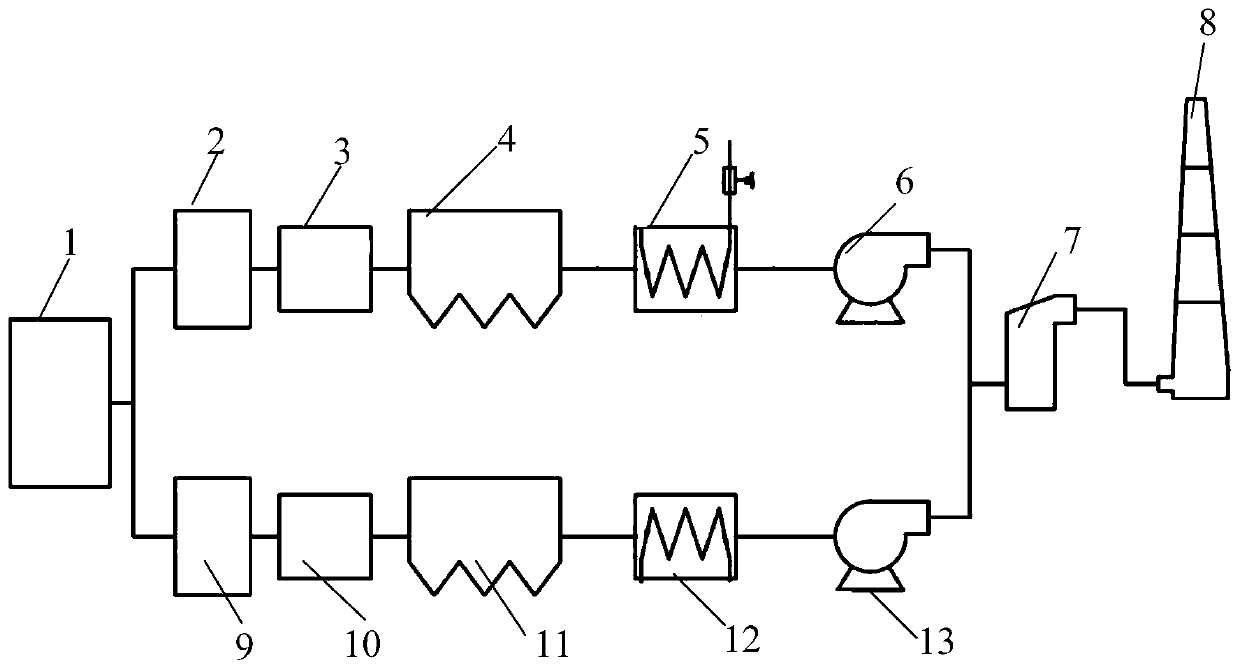

[0051] Such as figure 1 As shown, a flue gas flow measurement device at the inlet of an induced draft fan, including a boiler 1, a first SCR de-pinning device 2, a first air preheater 3, a first dust collector 4, and a first low-temperature economizer connected in sequence through pipelines 5. The first induced draft fan 6, the desulfurization tower 7 and the chimney 8, also includes the second SCR destocking device 9, the second air preheater 10, the second dust collector 11, the second low temperature economizer 12 and the second induced draft fan 13 , the boiler 1, the second SCR depinning device 9, the second air preheater 10, the second dust collector 11, the second low temperature economizer 12, the second induced draft fan 13 and the desulfurization tower 7 are connected in sequence through pipelines.

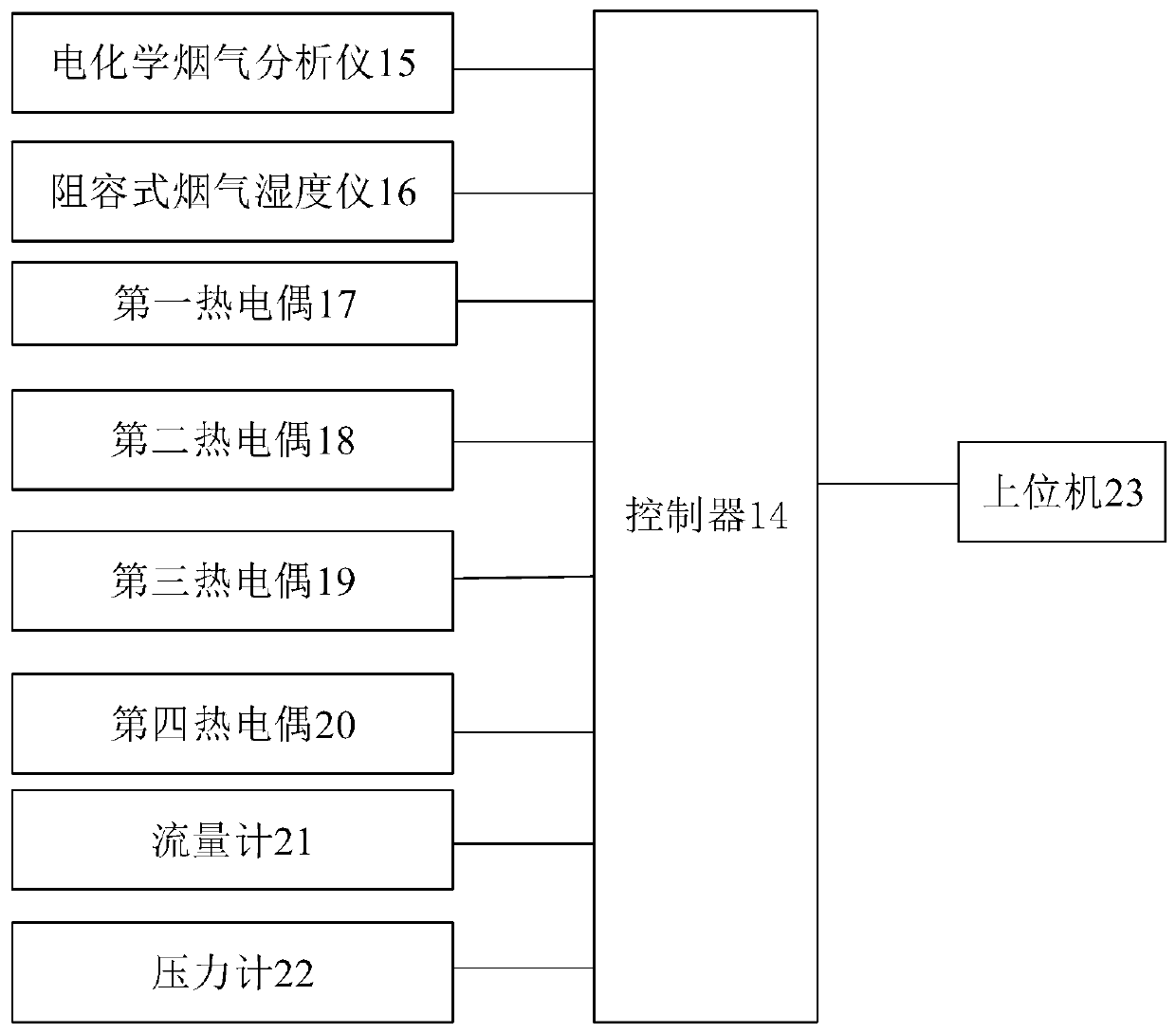

[0052] Such as figure 2 As shown, the pipeline in front of the first low-temperature economizer 5 is provided with an electrochemical flue gas analyzer 15 electrically...

Embodiment 2

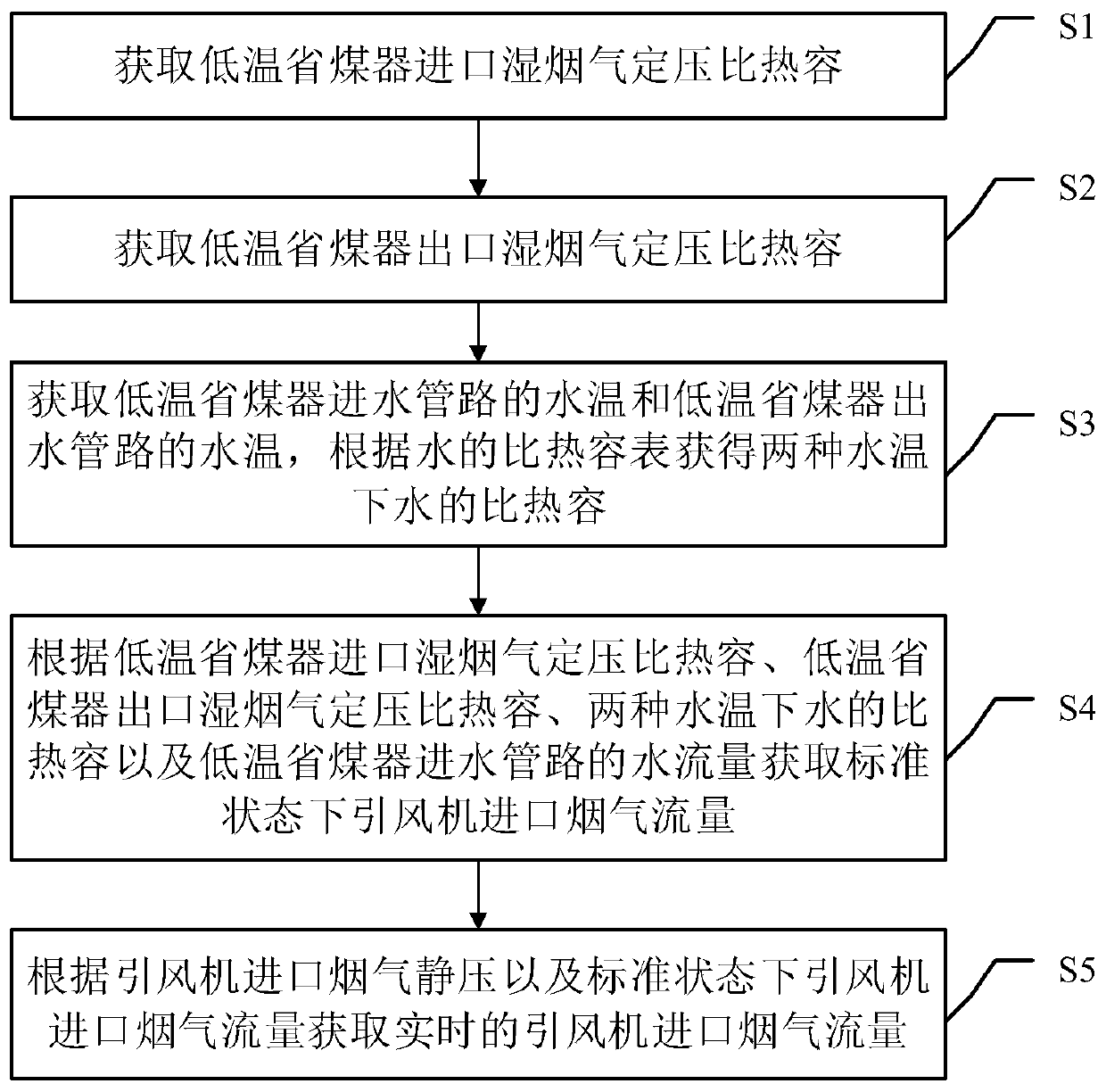

[0057] Such as image 3 As shown, corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention also provides a method for measuring flue gas flow at the inlet of an induced draft fan, which is applied to a coal-fired power unit equipped with a low-temperature economizer. The method includes:

[0058] Step S1: Obtain the specific heat capacity of wet flue gas at constant pressure at the inlet of the low-temperature economizer; the specific process is:

[0059] Collect the volume fraction φ of oxygen in the dry flue gas imported from the low-temperature economizer O2 , the volume fraction of carbon dioxide in dry flue gas φ CO2 , the volume fraction of water vapor in wet flue gas φ H2O and inlet flue gas temperature T fg.en ;

[0060] Neglecting the influence of trace amounts of carbon monoxide, nitrogen oxides and sulfur dioxide in the flue gas, the formula φ N2 =100-φ O2 -φ CO2 Obtain the volume fraction of nitrogen in the dry flue gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com