Scribing device for glass cutting

A scribing device and glass cutting technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of kerosene time-consuming, labor-intensive, inaccurate manual scribing, etc., and achieve accurate scribing and force separation The effect of reducing and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

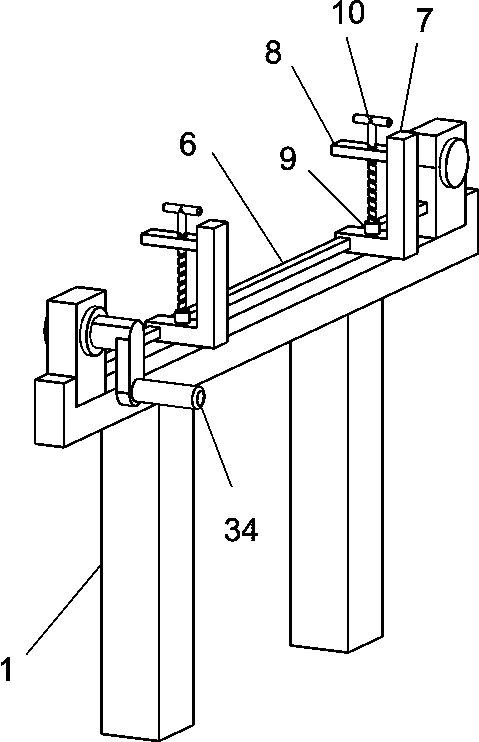

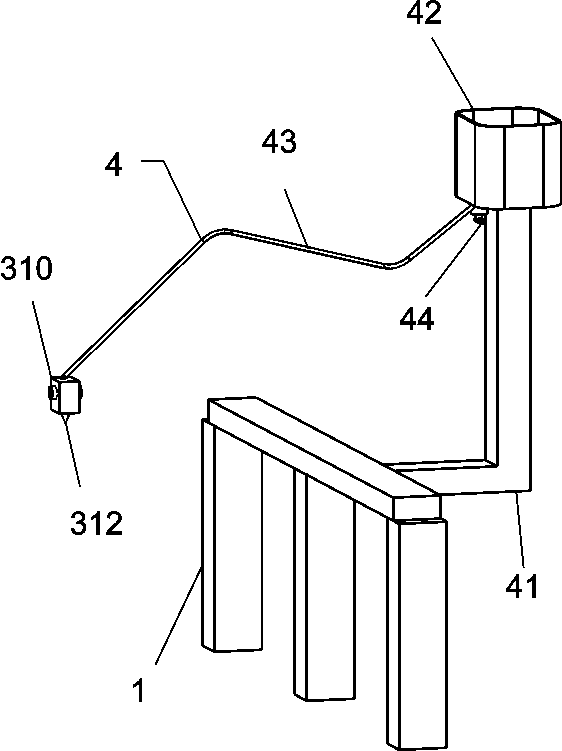

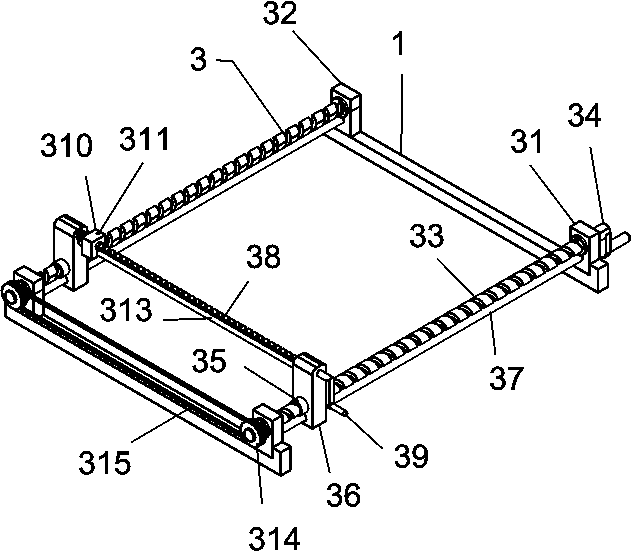

[0021] A scribing device for glass cutting, such as Figure 1-4 As shown, it includes a support frame 1, a support plate 2, a marking mechanism 3 and a refueling mechanism 4. The top of the support frame 1 is fixedly connected with a support plate 2, and the front and rear sides of the support plate 2 are provided with a marking mechanism 3. The front side of the support plate 2 is provided with a refueling mechanism 4, and the lower part of the refueling mechanism 4 is connected with the support frame 1.

[0022] Before the glass 5 is cut, the glass 5 must be marked. First, the glass 5 is placed on the support plate 2, and then the marking mechanism 3 is operated to adjust to the position to be cut. Kerosene, finally press the glass 5 by hand, then run the marking mechanism 3 to mark the glass 5, and then close the refueling mechanism 4 after marking the line, so that the glass 5 can be accurately marked.

[0023] As a further preferred solution, the marking mechanism 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com