Seabed frame fixed type group anchor system

A fixed, frame technology, applied in anchor points, ship parts, transportation and packaging, etc., can solve the problems of poor installability, no new anchor type near islands and reefs, and high labor and material costs, so as to improve economy and efficiency. , Excellent engineering feasibility and good work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

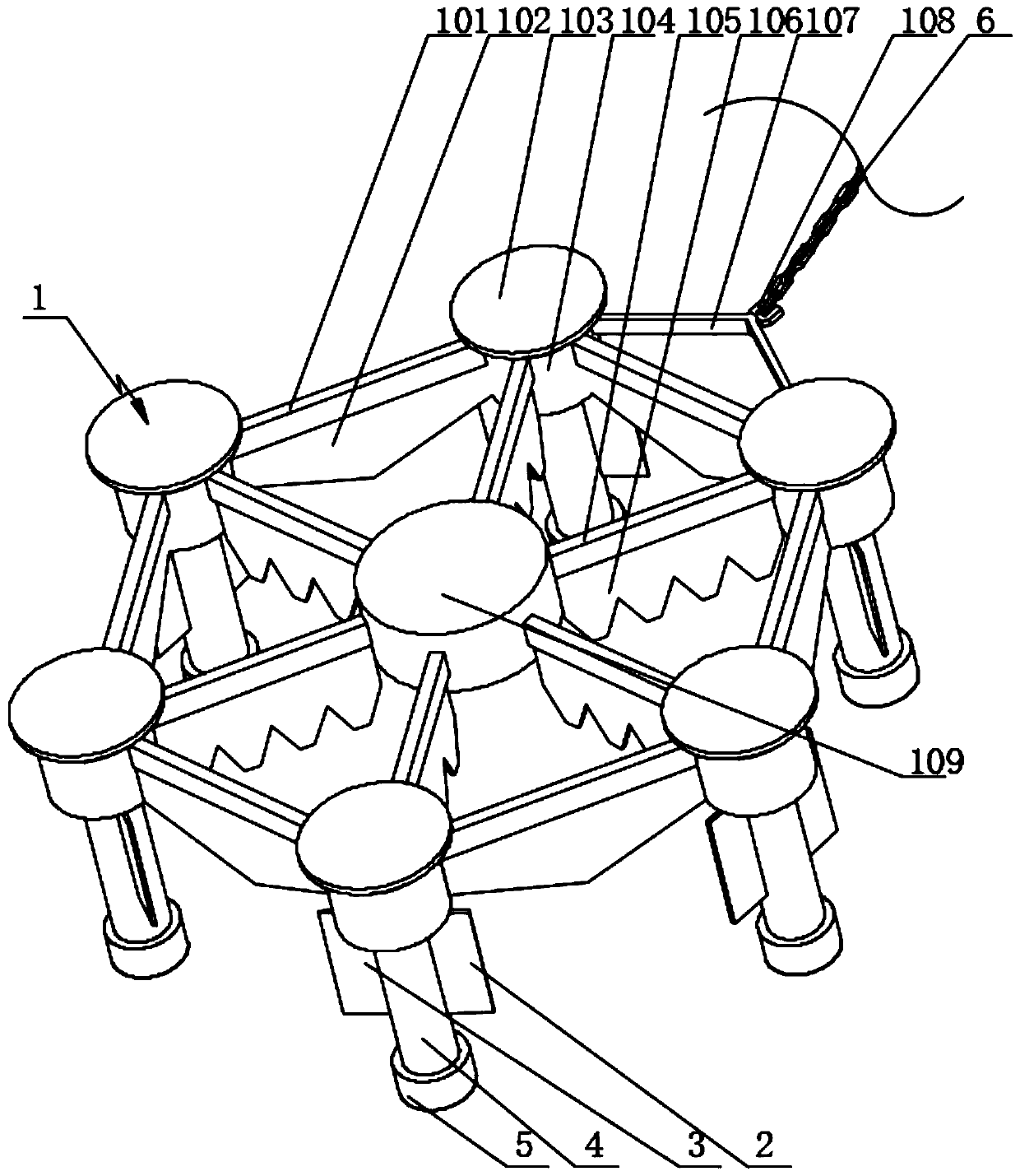

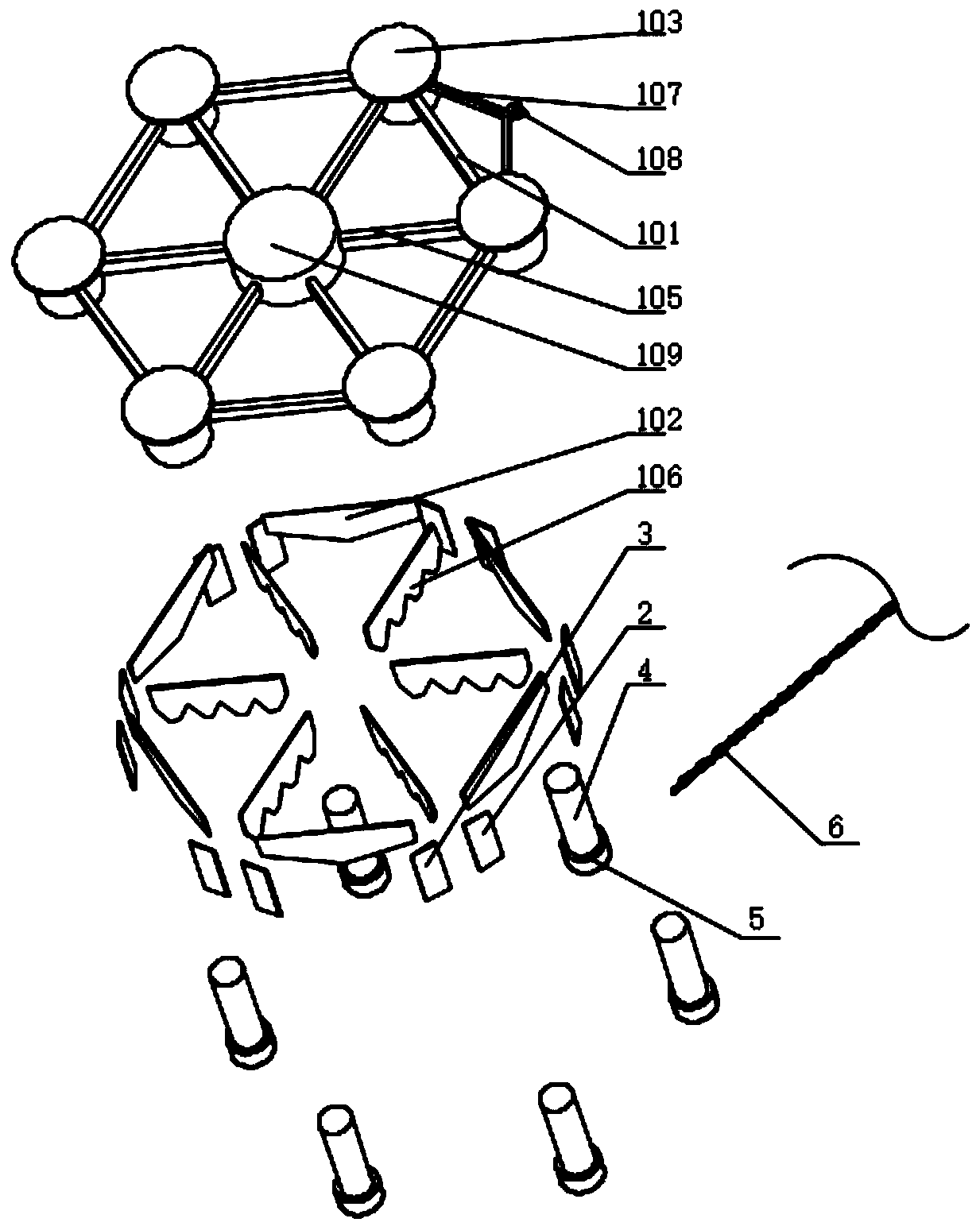

[0030] Such as figure 1 , figure 2 with image 3 As shown, the submarine frame fixed group anchor system of this embodiment includes an anchor frame assembly 1, the top of which is a hexagonal anchor structure, and a central short cylinder structure 109 is set in the middle, and the central short cylinder The outer circumference of the structure 109 is evenly spaced with six radial channel steels 105, the head of each radial channel steel 105 is connected to a hollow cylindrical shell 104, and the top of each hollow cylindrical shell 104 is equipped with an upper end cover 103 , two adjacent hollow cylindrical shells 104 are connected by external channel steel 101, and six external channel steel 101 are connected to form a hexagonal structure;

[0031] The bottom of each external channel steel 101 is equipped with a triangular plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com