A polyurethane foam machine

A foaming machine and polyurethane technology, applied in the field of machinery, can solve the problems affecting the quality of foamed products and uneven mixing of raw materials, and achieve the effects of improving the distribution and mixing effect, expanding the entry area, and increasing the throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

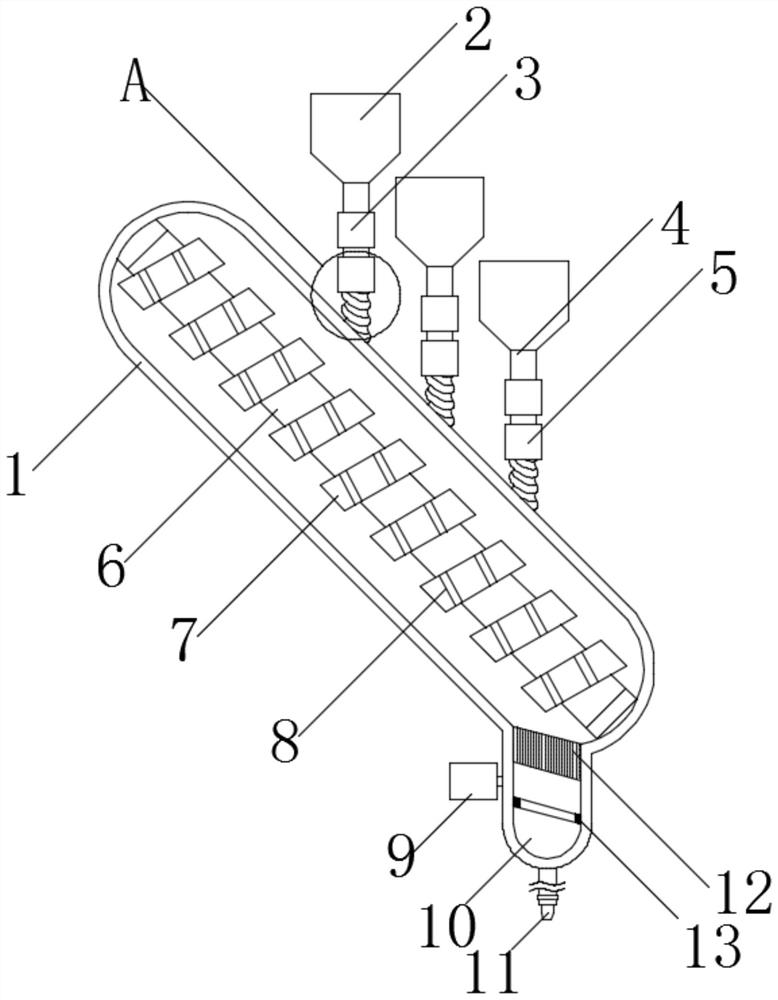

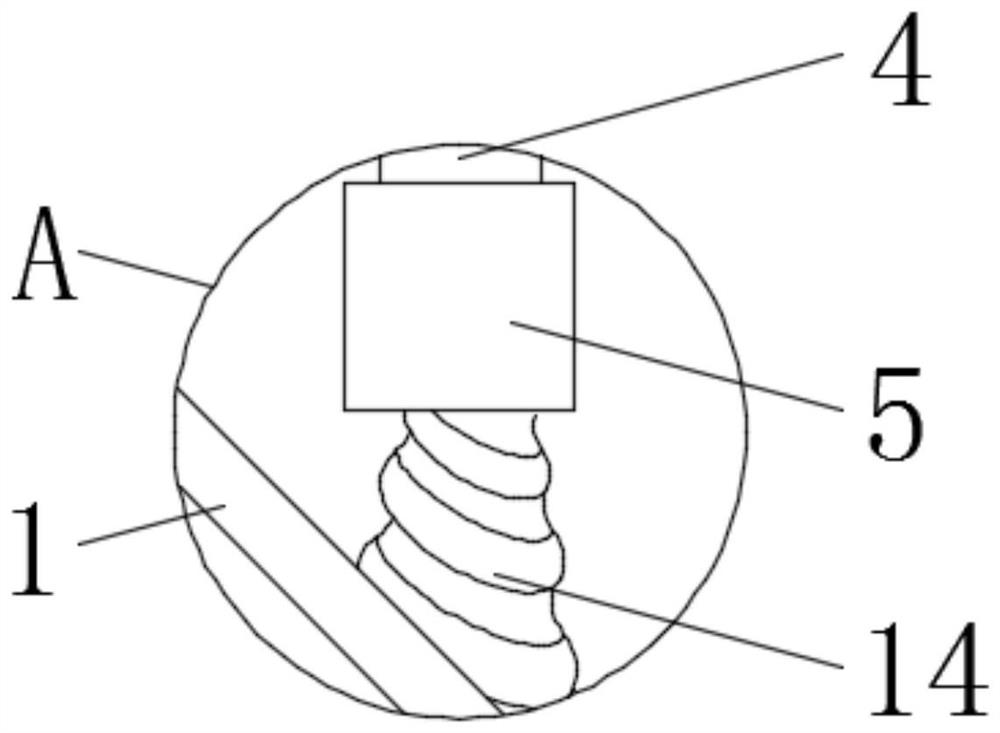

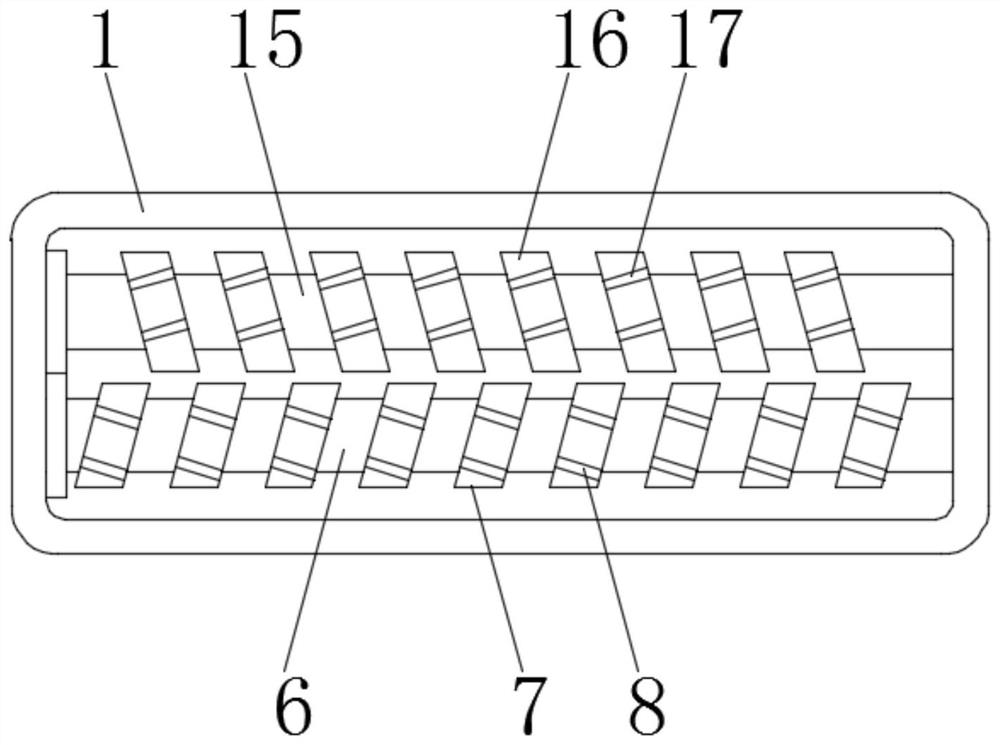

[0025] see Figure 1-5 , the present invention provides a technical solution: a polyurethane foaming machine, comprising a housing 1, a feed bin 2 and a drive shaft 6, a feed bin 2 is arranged above the housing 1 and the number of feed bins 2 is multiple groups, The bottom of the silo 2 is connected with a feeding pipe 4, the bottom of the feeding pipe 4 is connected with a first pressure pump 3, and the bottom of the first pressure pump 3 is connected with a metering pump 5, and the housing 1 The inner cavity of the drive shaft 6 is installed with a first vane 7 installed on the outer side wall of the first vane 7, and a first groove 8 is opened on the outer side wall of the first vane 7, and the bottom of the housing 1 communicates with a A dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com