Production process of polymerized diacid ferro-aluminum for water treatment

A technology for polymerizing bis-aluminum iron and its production process, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of increasing the production cost of bis-aluminum iron Problems such as the production process of aluminum-ferric acid and reduction of the production efficiency of aluminum-iron bis-acid, to achieve the effect of reducing the difficulty of cleaning, reducing the waste of raw materials, and ensuring the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

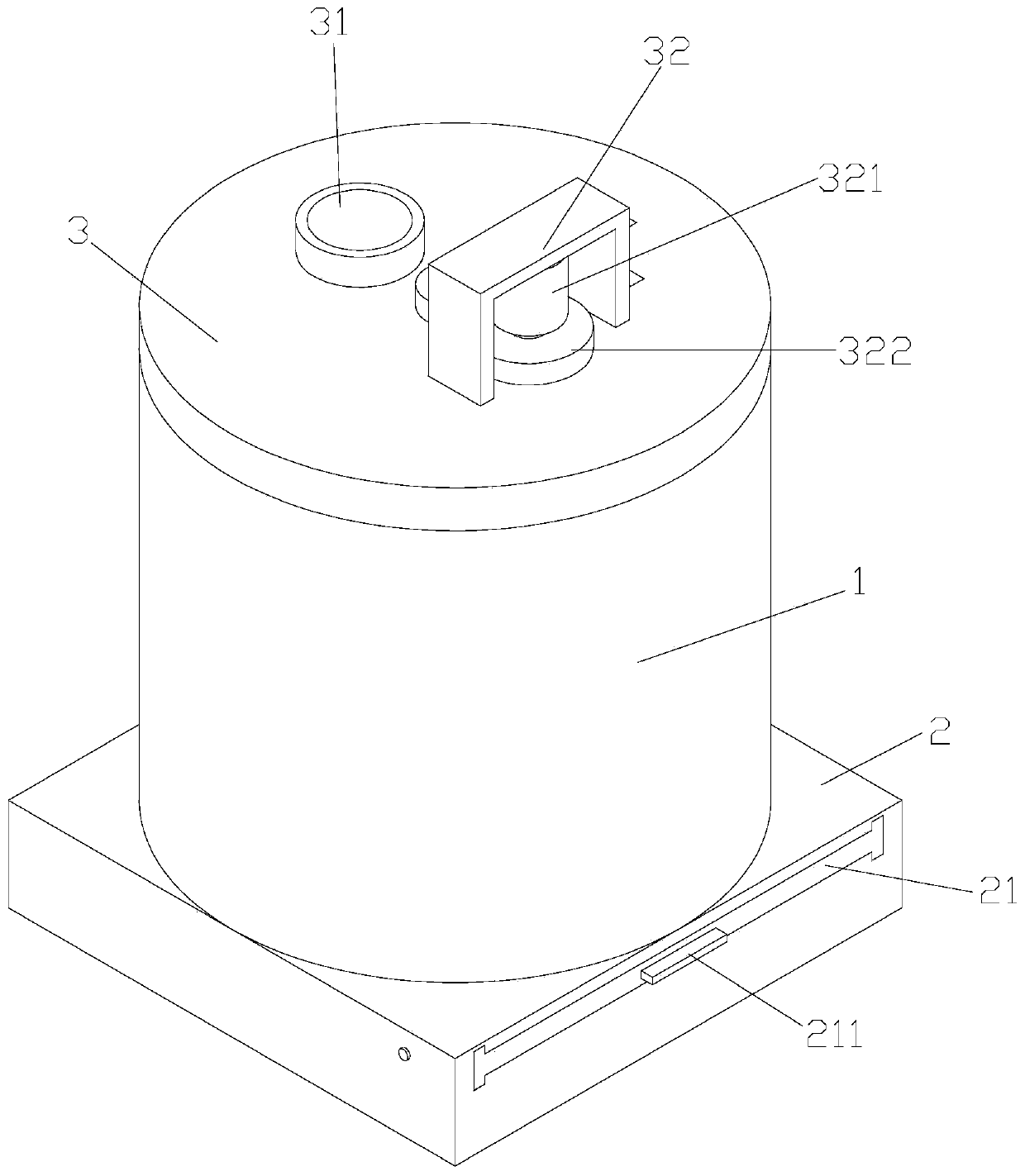

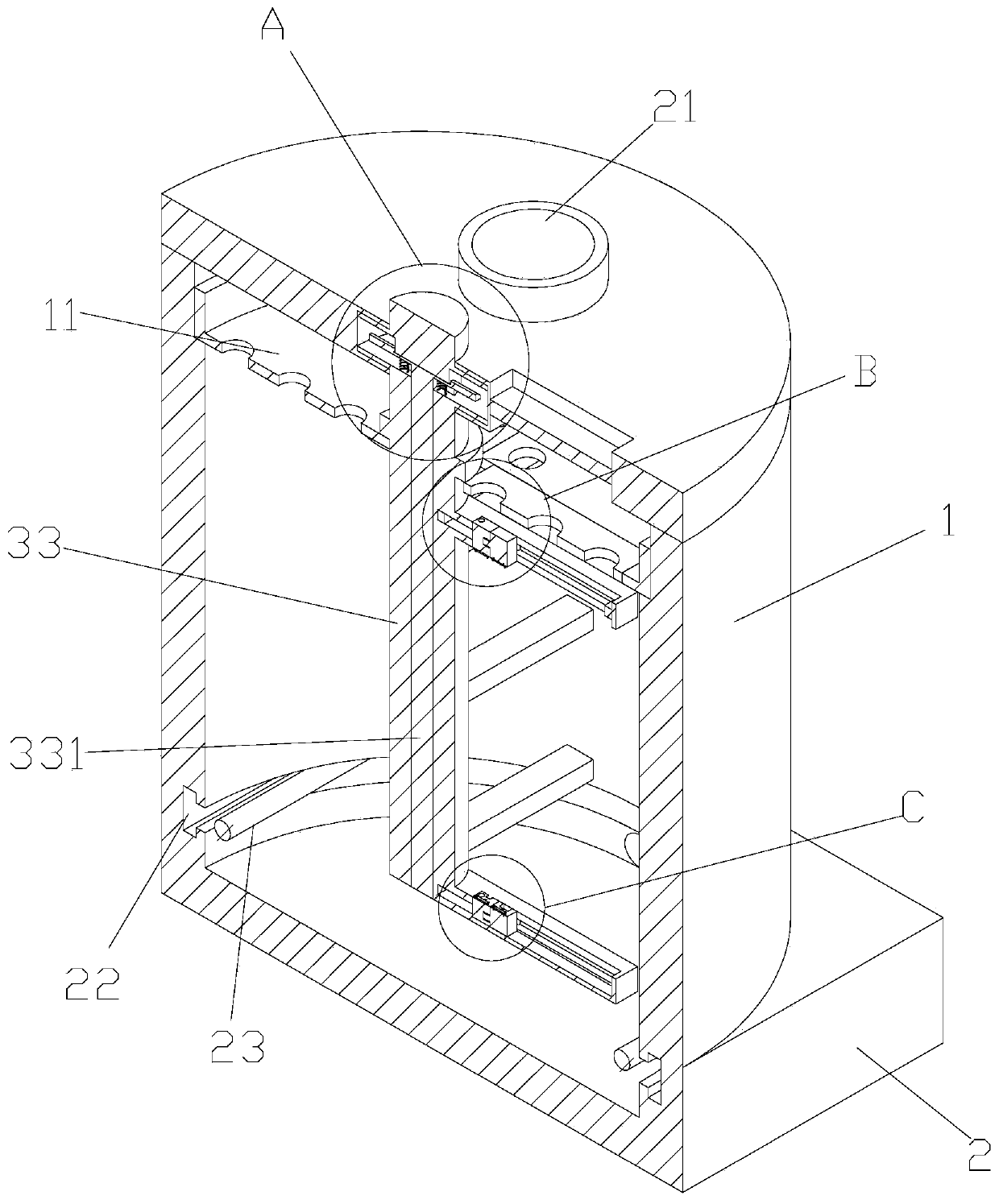

Image

Examples

Embodiment Construction

[0051] A kind of production technology of the polyaluminum iron bis-acid used for water treatment, comprising: a, under stirring, appropriate amount of water and 127~168 parts of hydrochloric acid of total acidity 30~32% and 8~14 parts of sulfuric acid of 97~99% are reduced Put it into a reaction tank for mixing, add 35 to 58 parts of iron-containing bauxite powder with an alumina content of 40 to 45% and an iron oxide content of 20 to 25% at normal pressure and temperature, and stir until dissolved; Then continue to heat up until the temperature of the reaction system is controlled at 105-125°C, and react under normal pressure for 3.5-5.0 hours; b. Add an appropriate amount of water to the feed liquid obtained in step a under stirring, and add 46-63 parts of calcium aluminate powder, During the dosing process, use the self-heating of the reaction to increase the temperature of the feed liquid. After the dosing is completed, adjust the density of the feed liquid to ≥ 1.25g / ml, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com