Aluminum electrolytic capacitor low-voltage aluminum foil corrosion process

A technology of aluminum electrolytic capacitors and aluminum foils, which is applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of low specific volume, uneven corrosion, and performance degradation of corroded foils, and achieve uniform appearance, reduced specific surface area, and energy consumption. electric small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

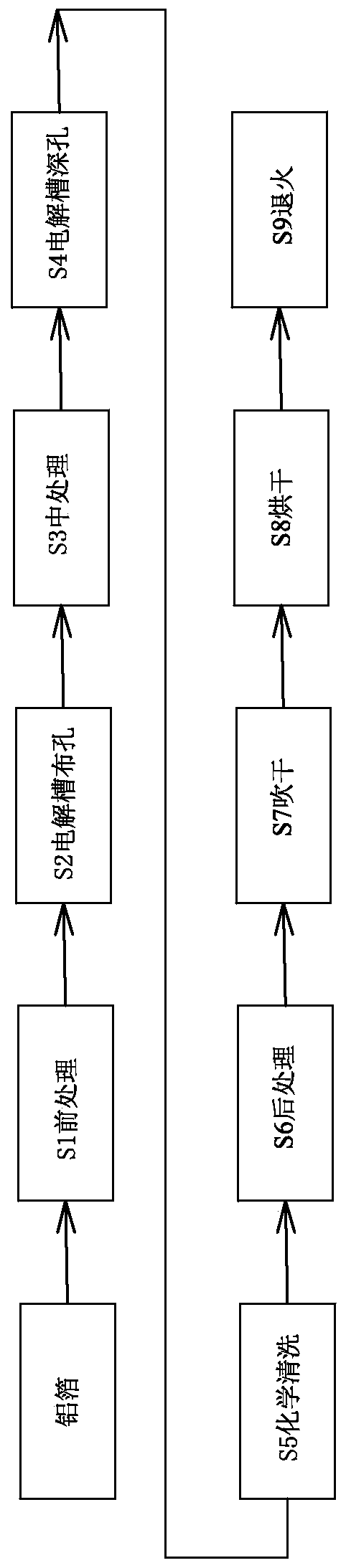

[0043] A low-voltage aluminum foil corrosion process for aluminum electrolytic capacitors, comprising the following steps:

[0044] S1, pre-processing:

[0045] Put the aluminum foil in phosphoric acid with a concentration of 0.5% for degreasing treatment at a temperature of 45°C for 1 minute, and then clean it with pure water;

[0046] S2. Electrolyzer hole layout:

[0047] Place the pre-treated aluminum foil in the electrolytic solution for electrolysis, wherein the electrolytic solution is an AlCl3 solution containing hydrochloric acid concentration: 7%, sulfuric acid, concentration 0.5%; power frequency: 25HZ, current: 350A, temperature: 35°C.

[0048] S3, middle processing:

[0049] Put the aluminum foil after the primary electrolytic cell is placed into the mixed corrosion solution at a temperature of 60°C for intermediate treatment, wherein the mixed corrosion solution is an AlCl3 solution containing 10% hydrochloric acid and 1% sulfuric acid;

[0050] S4. Deep hole...

Embodiment 2

[0063] A low-voltage aluminum foil corrosion process for aluminum electrolytic capacitors, comprising the following steps:

[0064] S1, pre-processing:

[0065] Put the aluminum foil in phosphoric acid with a concentration of 5% for degreasing treatment at a temperature of 60°C for 5 minutes, and then clean it with pure water;

[0066] S2. Electrolyzer hole layout:

[0067] Place the pretreated aluminum foil in the electrolytic solution for electrolysis, wherein the electrolytic solution is an AlCl3 solution containing hydrochloric acid concentration: 20%, sulfuric acid, concentration 1.5%; power frequency: 60HZ, current: 800A, temperature: 50°C.

[0068] S3, middle processing:

[0069]The aluminum foil after the primary electrolytic cell is placed in the mixed corrosion solution at a temperature of 80°C for intermediate treatment, wherein the mixed corrosion solution is an AlCl3 solution containing 20% hydrochloric acid and 3% sulfuric acid;

[0070] S4. Deep hole of el...

Embodiment 3

[0083] A low-voltage aluminum foil corrosion process for aluminum electrolytic capacitors, comprising the following steps:

[0084] S1, pre-processing:

[0085] Degreasing the aluminum foil in phosphoric acid with a concentration of 2% at a temperature of 50°C for 2 minutes, and then cleaning it with pure water;

[0086] S2. Electrolyzer hole layout:

[0087] Place the pre-treated aluminum foil in the electrolytic solution for electrolysis, wherein the electrolytic solution is an AlCl3 solution containing hydrochloric acid: 12%, sulfuric acid, and 1% concentration; power frequency: 40HZ, current: 500A, temperature: 40°C.

[0088] S3, middle processing:

[0089] Put the aluminum foil after the primary electrolytic cell is placed into the mixed corrosion solution at a temperature of 70°C for intermediate treatment, wherein the mixed corrosion solution is an AlCl3 solution containing 15% hydrochloric acid and 2% sulfuric acid;

[0090] S4. Deep hole of electrolyzer:

[0091]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com