MEMS palladium alloy probe testing method and probe loading method thereof

A test method, palladium alloy technology, applied in the measurement device, using stable bending force to test material strength, using stable tension/pressure test material strength and other directions, can solve the problem of heat dissipation, which is difficult to solve, narrow in field, and no discovery Palladium alloy probe test equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0103] The following is a specific embodiment of the MEMS palladium alloy probe testing device of the present invention.

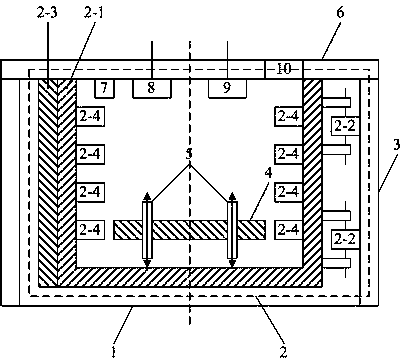

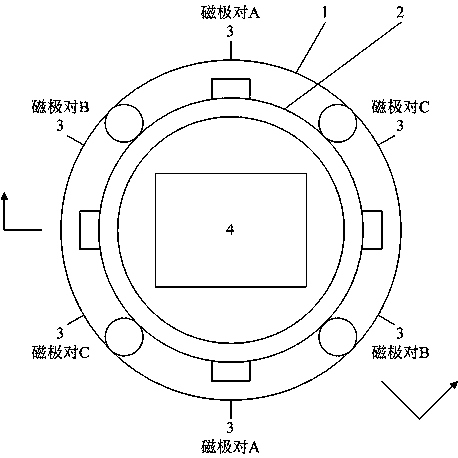

[0104] The MEMS palladium alloy probe testing device under the present embodiment, the structure schematic diagram is as follows figure 1 shown. The MEMS palladium alloy probe testing device comprises a barrel-shaped housing 1, a disturbance structure 2 arranged on the inner wall of the barrel-shaped housing 1, an electromagnetic pole 3 arranged on the outer wall of the barrel-shaped housing 1, and arranged horizontally in the barrel-shaped housing 1 Placed reference test platform 4, a symmetrical bending test structure 5 positioned above the reference test platform 4, a sealing cover 6 arranged above the barrel-shaped housing 1 and a sensor 7 installed on the sealing cover 6, a sprayer 8, a heater 9 and fan 10;

[0105] The disturbance structure 2 includes a disturbance body 2-1 with a circular cross section, a roller 2-2 and a tooth structure 2-3 dispo...

specific Embodiment approach 2

[0112] The following is a specific embodiment of the MEMS palladium alloy probe testing device of the present invention.

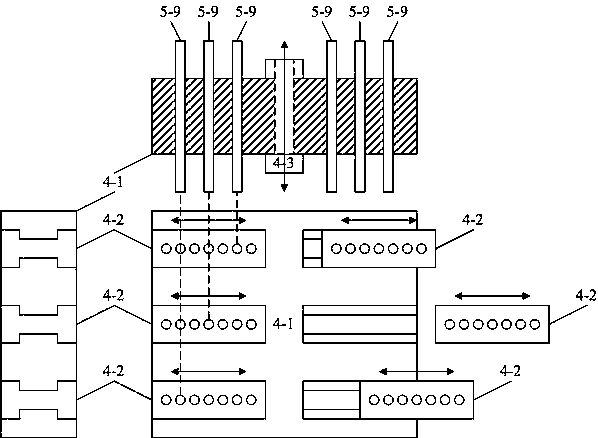

[0113] The MEMS palladium alloy probe test device under the present embodiment, on the basis of the specific embodiment one, further defines that the benchmark test platform includes a main board 4-1 and a plurality of sliders 4-2, and the main board 4-1 is provided with There are gaps from both sides to the center of symmetry, the cross-sectional shape of the gap is "I" shape, a slider 4-2 is inserted in the gap, and a plurality of vertical shafts are equally spaced on the slider 4-2 A circular through hole in a straight direction, the through hole can be equipped with a lifting structure 5-9, such as image 3 Shown; The material of described main board 4-1 and slide block 4-2 is different, specifically as follows:

[0114] First, the speed at which the volume of the material of the main board 4-1 increases with the increase of temperature is lower than ...

specific Embodiment approach 3

[0120] The following is a specific implementation of the benchmark test platform in the MEMS palladium alloy probe test device of the present invention.

[0121] The benchmark test platform under the present embodiment includes a main board 4-1 and a plurality of sliders 4-2, the main board 4-1 is provided with a gap from both sides to the symmetrical center direction, and the cross-sectional shape of the gap is "I" shape, a slider 4-2 is inserted in the gap, and a plurality of circular through holes in the vertical direction are equally spaced on the slider 4-2, and the through holes can be installed with a lifting structure 5- 9, such as image 3 Shown; The material of described main board 4-1 and slide block 4-2 is different, specifically as follows:

[0122] First, the speed at which the volume of the material of the main board 4-1 increases with the increase of temperature is lower than that of the material of the slider 4-2 with the increase of temperature. Before testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com