Pipeline position detection method based on three-dimensional scanning

A technology of three-dimensional scanning and pipeline position, which is applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of inconvenient inspection, many measurements, and long inspection time, so as to achieve obvious convenience in measurement and solve the problem of pipeline Detect and apply flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

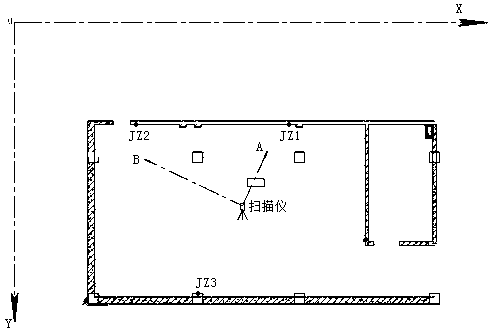

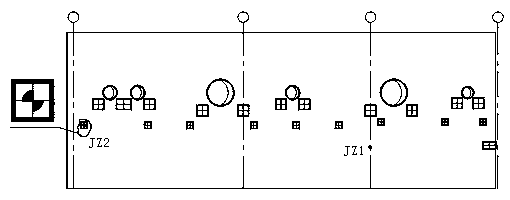

[0027] A method for checking the position of a pipeline based on HDS7000 three-dimensional scanner technology provided in this embodiment, such as figure 1 and figure 2 As shown, the origin of the construction coordinate system is the intersection of the ground and the two side walls, the X-axis is the intersection line parallel to the ground and the wall, the Y-axis is vertical to AX on the ground, and the H-axis is upward, which conforms to the right-handed coordinate system. The plane formed by the A-axis and the B-axis of the instrument coordinate system is parallel to the ground and also conforms to the right-handed coordinate system, including the following steps:

[0028] The first step, marking - marking the reference point of the wall embedded parts, three points form a plane, and the positions are evenly distributed;

[0029] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com