Transition beam assembly and inspection device

An inspection device and transition beam technology, which is applied to measuring devices, ground devices, and mechanical devices, etc., can solve the problems of time-consuming, repeated setbacks, and inaccurate positioning of rear beam components, and achieves a simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the examples are only used to explain the invention, but not to limit the scope of the invention.

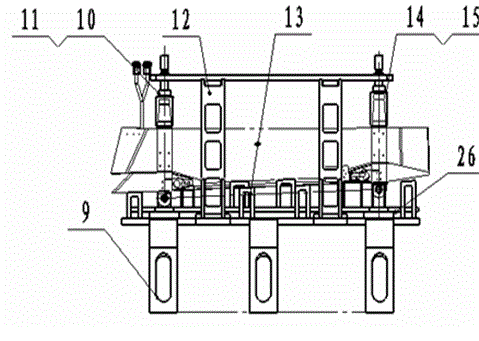

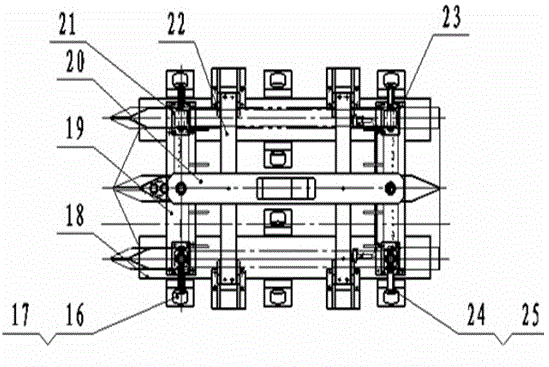

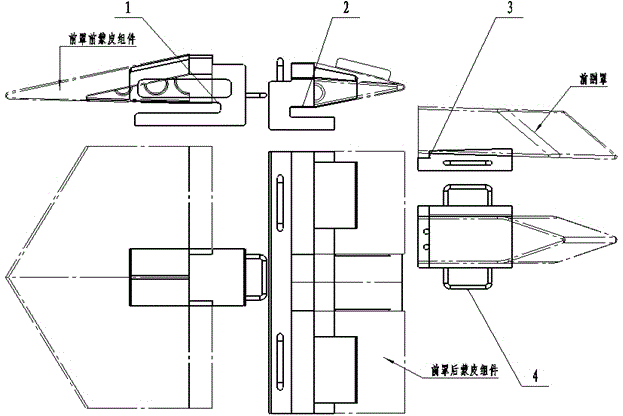

[0014] An assembly and inspection device of a transition beam, including a main assembly assembly, the main assembly assembly includes a base 9, an upper and front positioning pin 10, an upper and front inspection pin 11, a vertical plate 12, a skin positioning inspection block 13, an upper and rear positioning Pin 14, upper and rear inspection pin 15, lower front positioning pin 16, lower front inspection pin 17, bottom plate 18, horizontal positioning plate 19, upper positioning plate 20, front positioning block 21, upper horizontal plate 22, rear positioning block 23, lower The rear positioning pin 24, the lower rear inspection pin 25 and the lower connecting plate 26, the bottom plate 18 is placed on the base 9, the front positioning block 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com