Automatic particle plastic dehumidification drying system and technology

A drying system and plastic technology, applied in the direction of drying solid materials, dry cargo handling, drying gas arrangement, etc., can solve the problems of large drying load, easy softening, and sticking together of the drying device, so as to reduce the drying load and increase the contact area , the effect of increasing the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

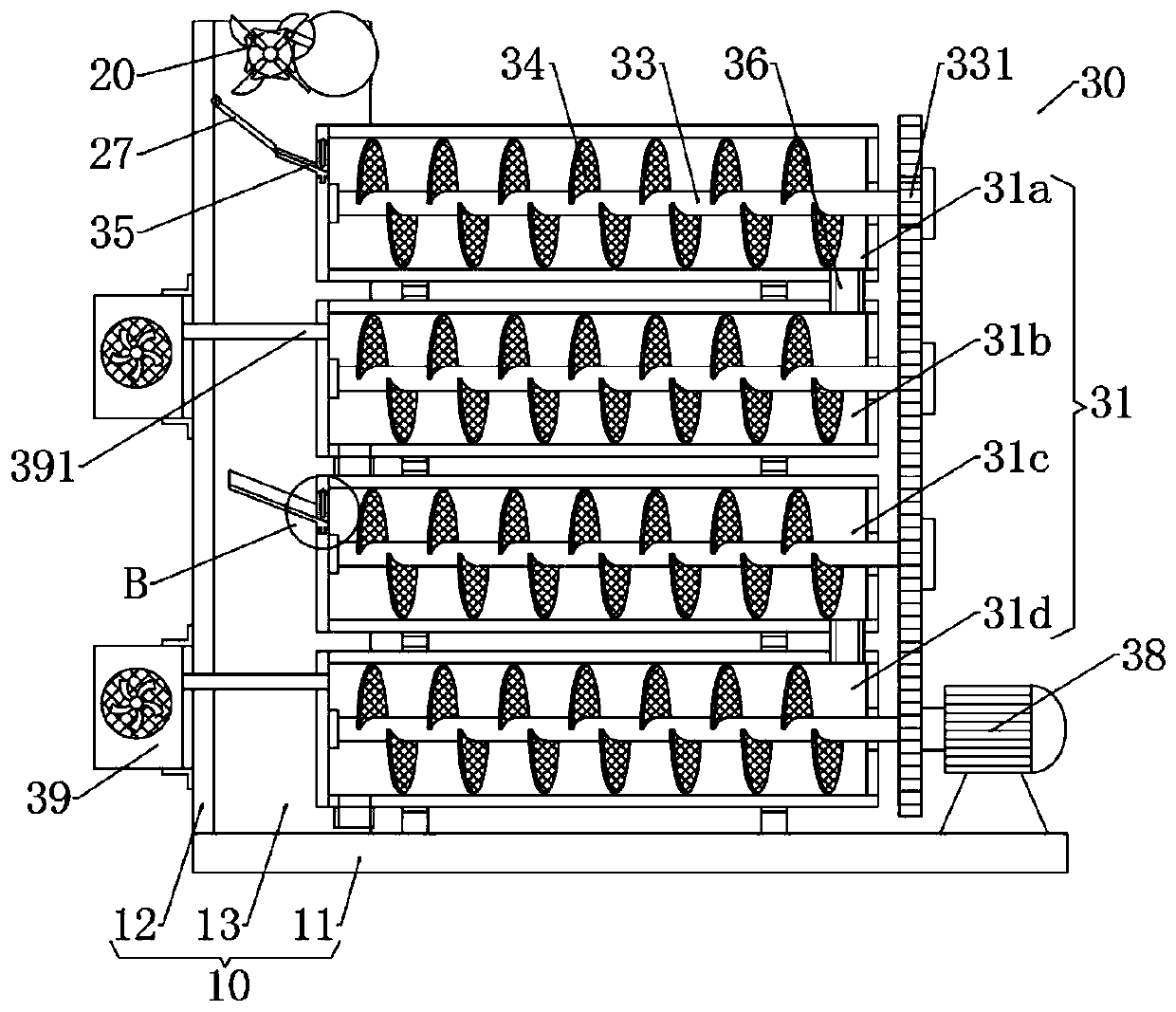

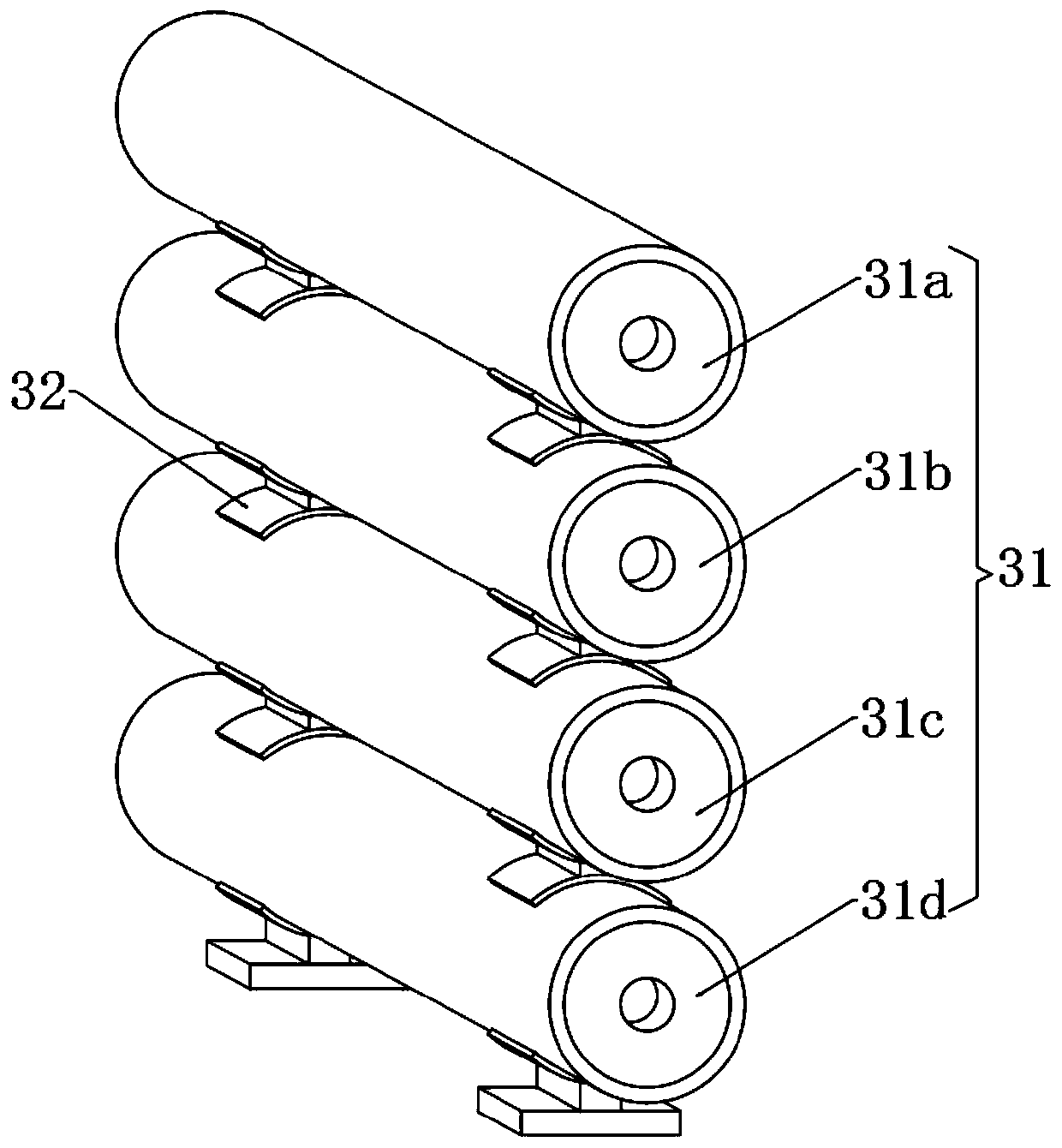

[0037] like figure 1 and figure 2 As shown, a granular plastic automatic dehumidification and drying system includes a base 10, a distribution device 20 installed on the base 10, and a drying device 30. The base 10 includes a bottom plate 11 and a side plate 12 vertically arranged at one end of the bottom plate 11. The bottom plate The top of 11 is located on the back side of side plate 12 and is vertically provided with back plate 13, and back plate 13 and side plate 12 are fixedly connected and perpendicular to each other, material distribution device 20 is located at the top of back plate 13, and drying device 30 is located at the top of bottom plate 11;

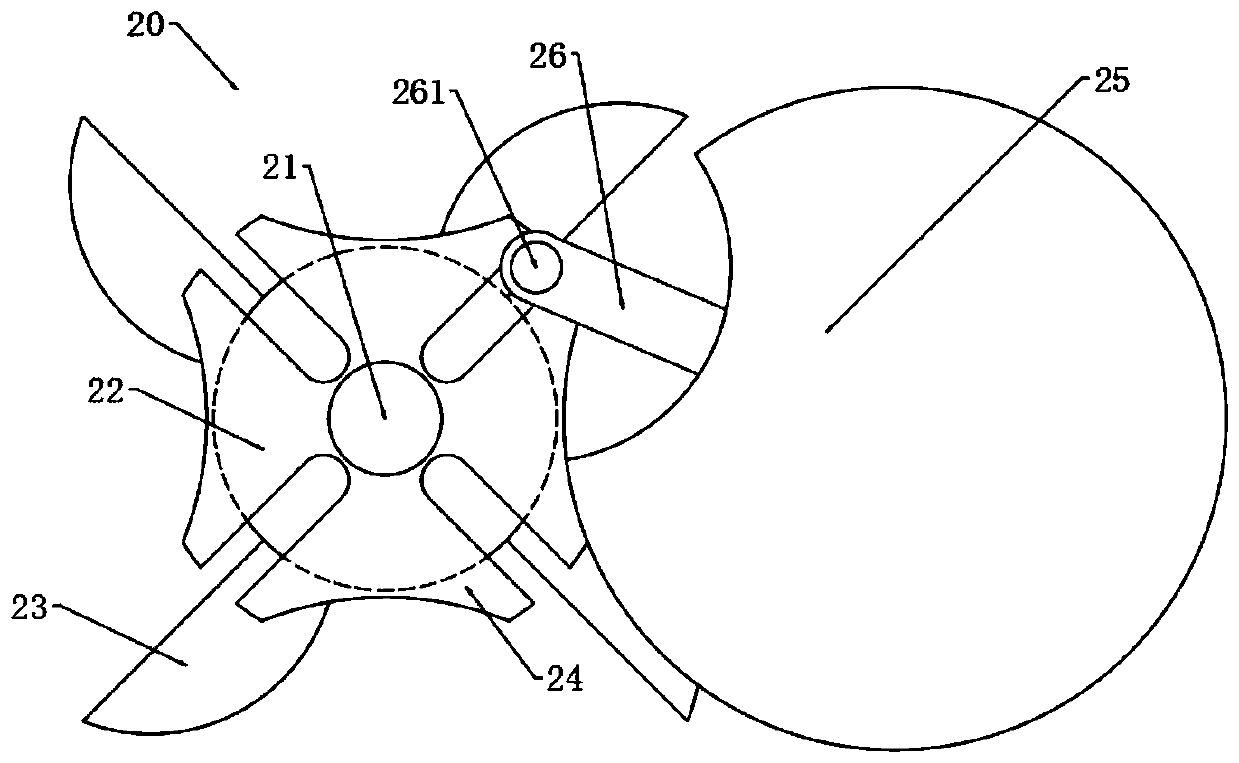

[0038]The material distribution device 20 includes a central shaft 21 vertically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com