An Efficient Vacuum Drying Device for Nanomaterial Powder

A vacuum drying device and nanomaterial technology, which are applied in the directions of promoting the drying of solid materials, drying goods, drying solid materials, etc., can solve problems such as poor drying effect of vacuum dryers, and achieve the effect of ensuring air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

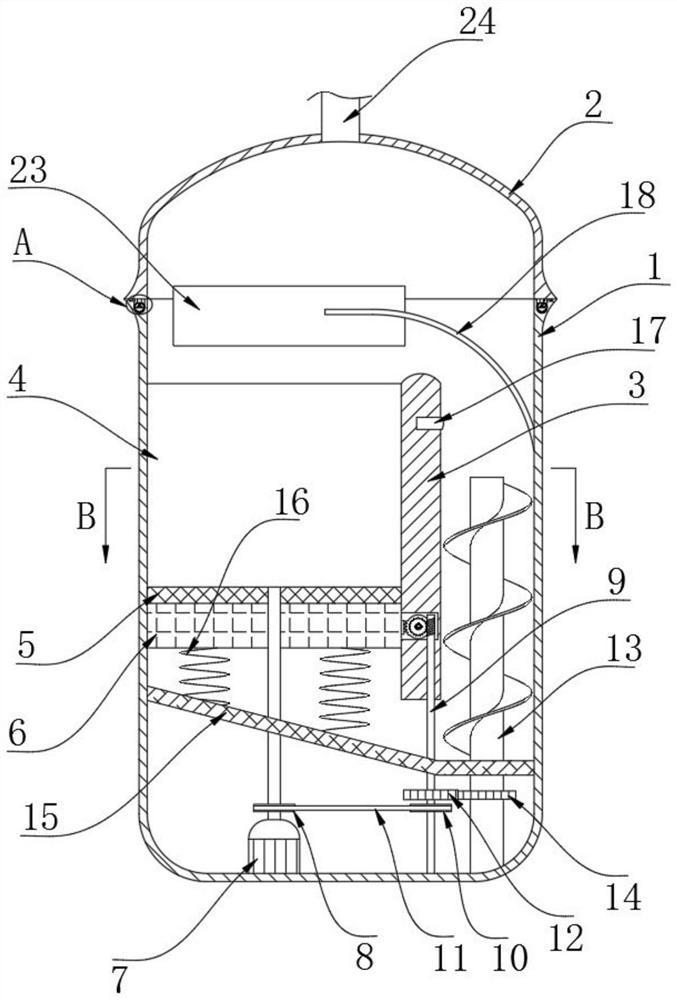

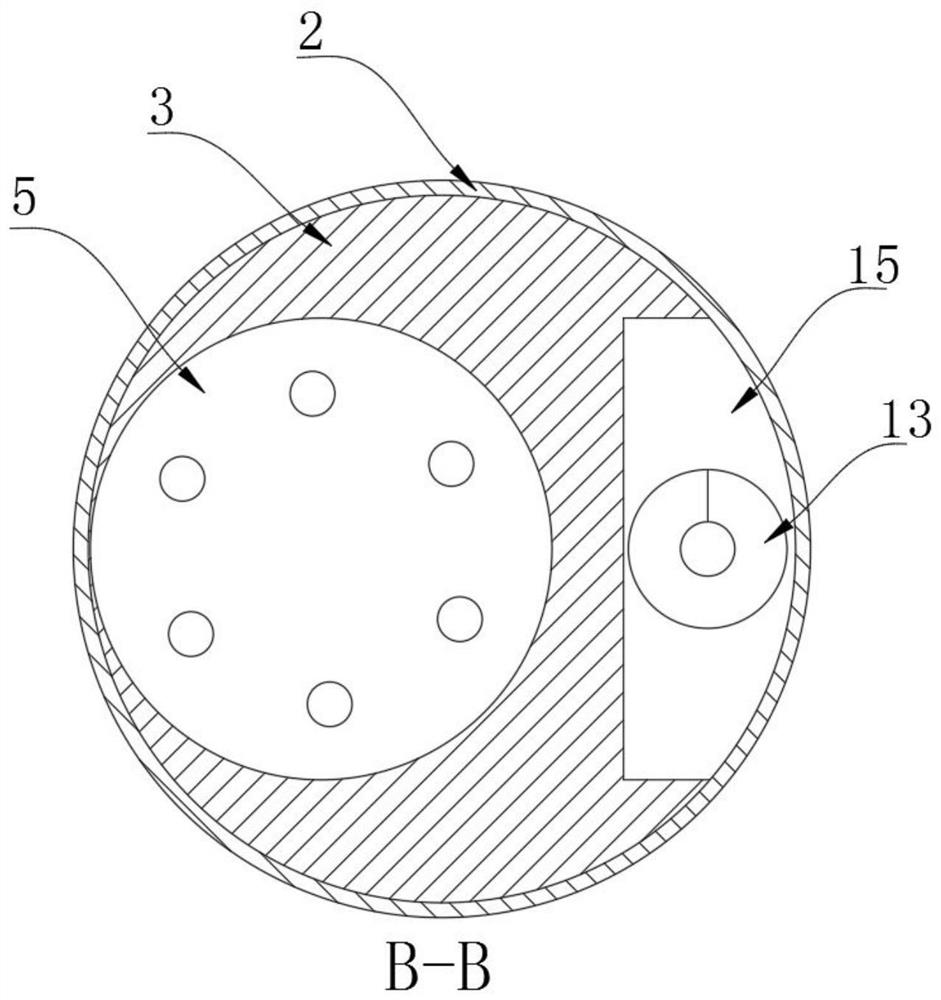

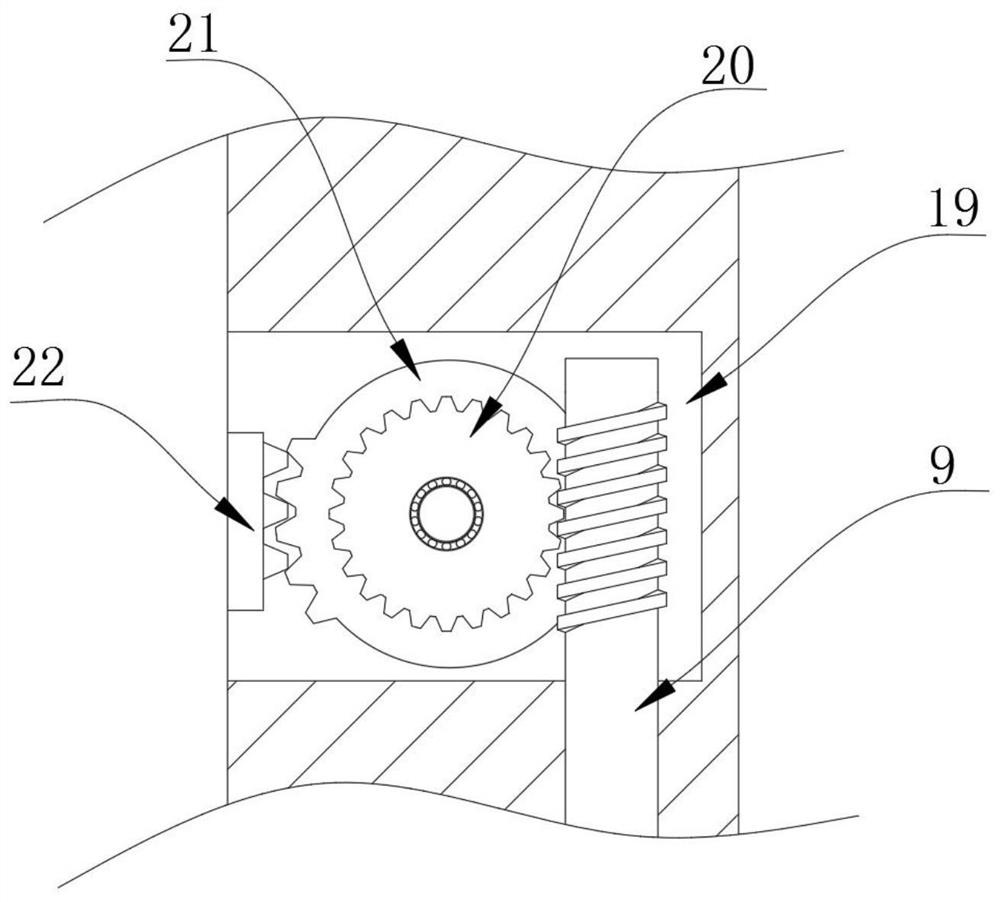

[0026] refer to Figure 1-4 , a highly efficient vacuum drying device for nanomaterial powder, including a kettle body 1 and a cover body 2, the cover body 2 is set directly above the kettle body 1, and a partition 3 is fixed on the inner wall of the kettle body 1, and the partition board 3 The inner ring forms a cylindrical grinding chamber 4, the inner wall of the grinding chamber 4 is sealed and slidably connected with a grinding plate 5, the inner lower wall of the kettle body 1 is fixedly connected with a motor 7, and the upper end of the motor 7 is fixedly connected with a slanting plate 15. Plate 15 is positioned at the below of dividing plate 3, and the output shaft of motor 7 runs through swash plate 15 and is fixedly connected with the axle center of grinding plate 5, and the upper wall of swash plate 15 is fixedly connected with a plurality of back-moving springs 16, and a plurality of back-moving springs 16 An extruding plate 6 is fixedly connected to the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com