Fire extinguishing system and construction method for fire protection engineering

A fire extinguishing system and engineering technology, used in fire rescue, safety valves, engine components, etc., can solve problems such as circuit damage, affecting the normal operation of smoke prevention and exhaust devices, and failure of fire dampers to open and close normally, and achieve the effect of avoiding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

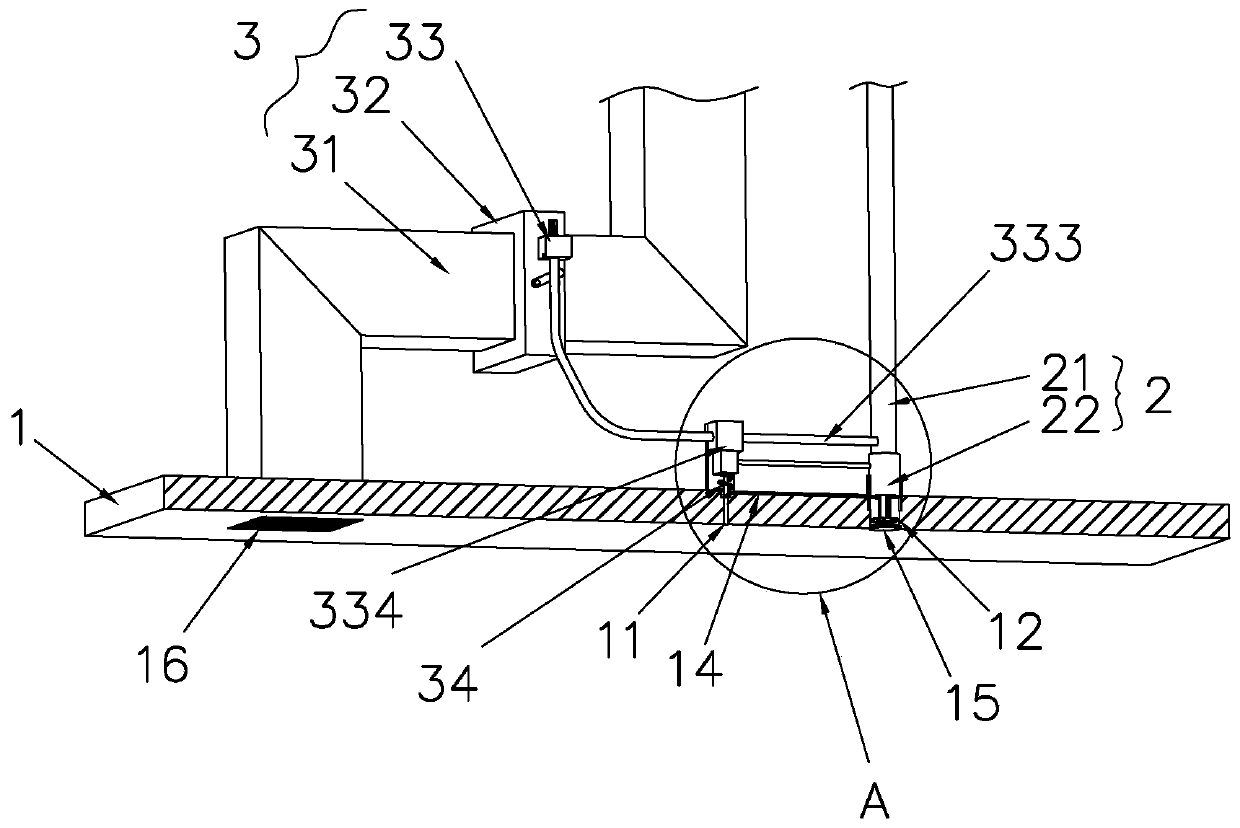

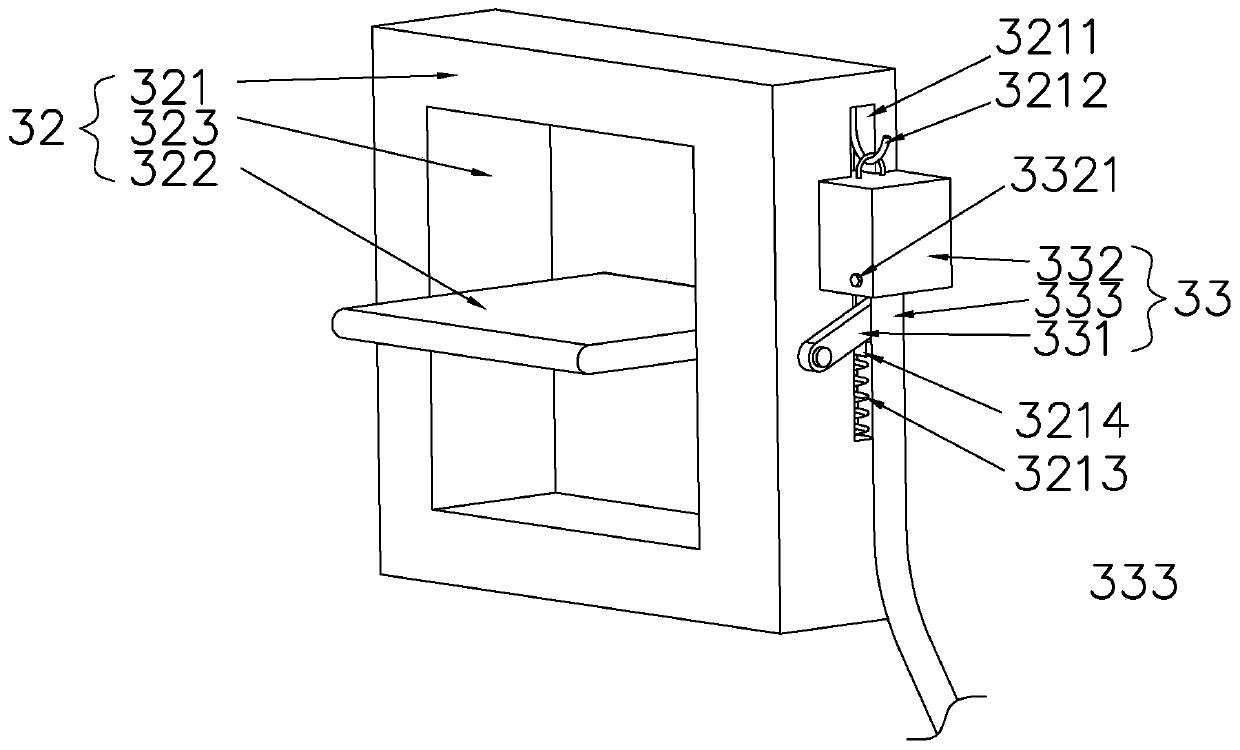

[0038] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] refer to figure 1 and figure 2 , is a fire extinguishing system for fire engineering disclosed by the present invention, which includes a heat conducting mounting plate 1 , an automatic sprinkler device 2 and a smoke prevention device 3 . The thermally conductive mounting plate 1 is made of high thermally conductive materials such as metal, and the thermally conductive mounting plate 1 is installed on ceilings and other positions.

[0040] The sprinkler 2 includes a water delivery pipeline 21 and a sprinkler head 22 arranged at the outlet end of the water delivery pipeline 21 . The water delivery pipeline 21 is located above the heat conduction mounting plate 1 , and the water delivery pipeline 21 communicates with the municipal water supply pipeline to obtain water from the municipal water supply pipeline. The shower head 22 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com