A magnetic energy accumulator

A technology of accumulators and magnetic energy, applied in the direction of actuator accumulators, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as potential safety hazards, energy storage loss, and explosive gas, achieving high safety and avoiding Explosion, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

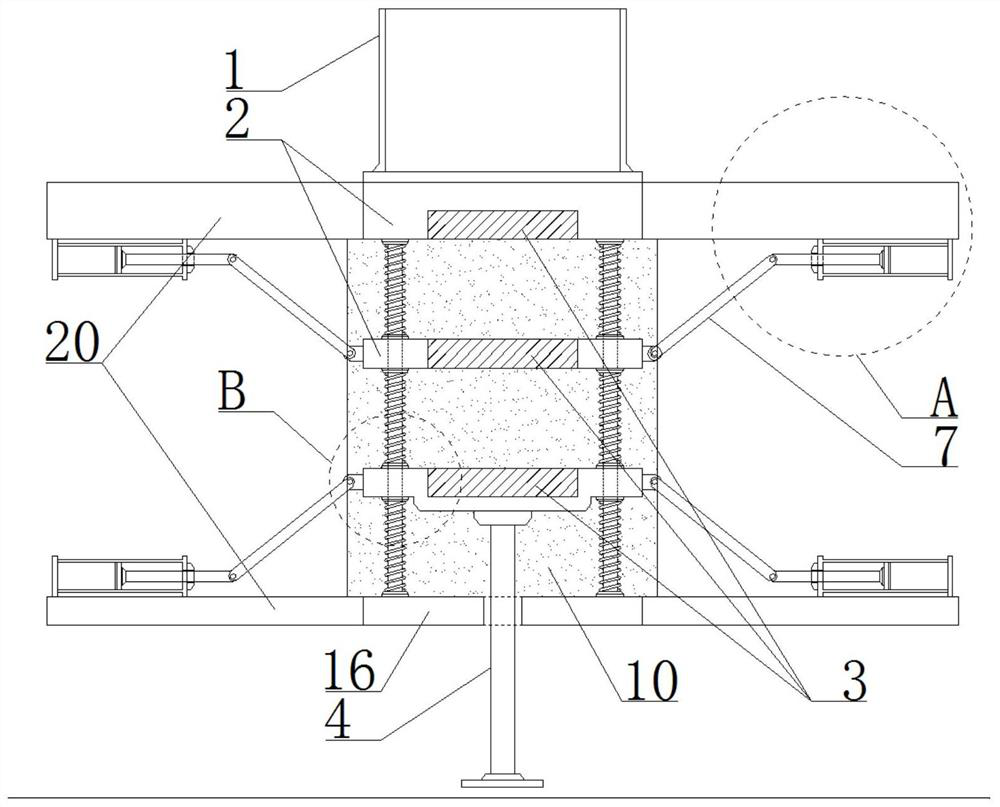

[0031] see Figure 1-9 , a magnetic energy accumulator, comprising a plurality of sets of magnetic mechanisms arranged up and down in sequence, a positioning mechanism, and an oil storage tank 1,

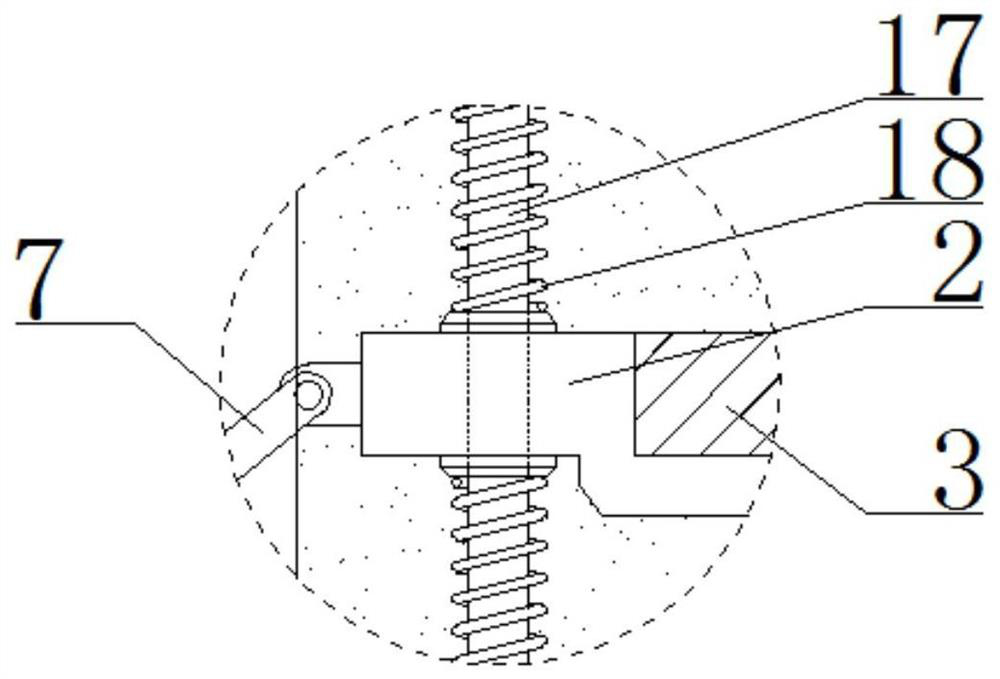

[0032] The magnetic mechanisms all include a mounting plate 2 and an electromagnet 3 nested in the mounting plate 2. Each group of magnetic mechanisms maintains relative movement along the vertical direction. The plates 2 remain relatively fixed, and each group of mounting plates 2 arranged below the uppermost layer is dynamically connected with a positioning mechanism, and the lower surface of the mounting plate 2 arranged at the lowest layer is consolidated with a power rod 4 and the power rod 4 is used as the energy of the accumulator. output input terminal;

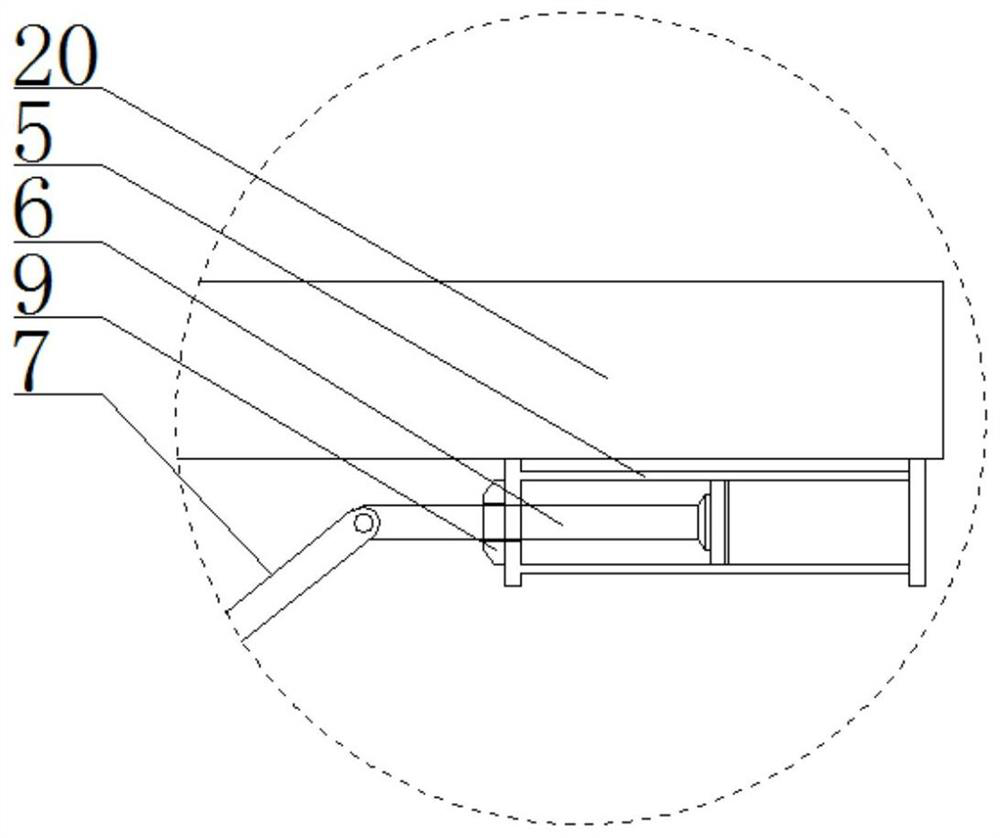

[0033] The positioning mechanism includes a positioning cylinder 5 and a positioning piston 6. The positioning piston 6 is nested in the positioning cylinder 5 and performs piston movement. The end of the positioning pisto...

Embodiment 2

[0035] see Figure 1-9 , to further describe Embodiment 1 in detail. In the present invention, the oil storage tank 1 is fixedly installed on the upper surface of the uppermost mounting plate 2, and under the action of no pressure, it can ensure that the hydraulic oil stored in the oil storage tank 1 flows in through the oil delivery pipe. Each group is positioned in the oil cylinder 5;

[0036] The mounting plate 2 and the corresponding electromagnet 3 are all in a cylindrical structure and arranged concentrically. A protective shell 10 is arranged on the periphery of each set of mounting plate 2. The overall structure of the protective shell 10 is a cylindrical structure to ensure that each group of magnetic mechanisms interacts stably and avoids The external environment and equipment affect it, and the protective shell 10 is provided with vertically arranged through holes relative to the direction in which the power rod 4 is set, so as to ensure that the movement of the mou...

Embodiment 3

[0039] see Figure 1-9 , the control principle of each electronic component and parts in the present application is explained: correspondingly connected with voltmeter 12, ammeter 13, circuit electronic switch 14 on the energization of each group electromagnet 3, voltmeter 12 is used for measuring electromagnet 3 when energizing Voltage value, ammeter 13 is used for the current value when electromagnet 3 is energized, circuit electronic switch 14 is used to control the on-off of the energized circuit of electromagnet 3, voltmeter 12, ammeter 13, circuit electronic switch 14, oil circuit electronic switch 8 The signal data of locking mechanism 9 is connected with single-chip microcomputer 15, through the single-chip microcomputer 15, the oil pipe is controlled to convey the on-off state of hydraulic oil to the corresponding positioning oil cylinder 5, and the on-off state of the energized circuit of the control electromagnet 3 is then controlled. Magnetic state, and the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com