Kitchen and bathroom waterproof guide wall and plate integral pouring shaping mold construction method

A technology of integral pouring and construction method, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, construction, etc. It can solve the problems of poor waterproof effect and inability to fully guarantee the molding quality. Achieve the effects of easy sealing, remarkable environmental protection effect and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

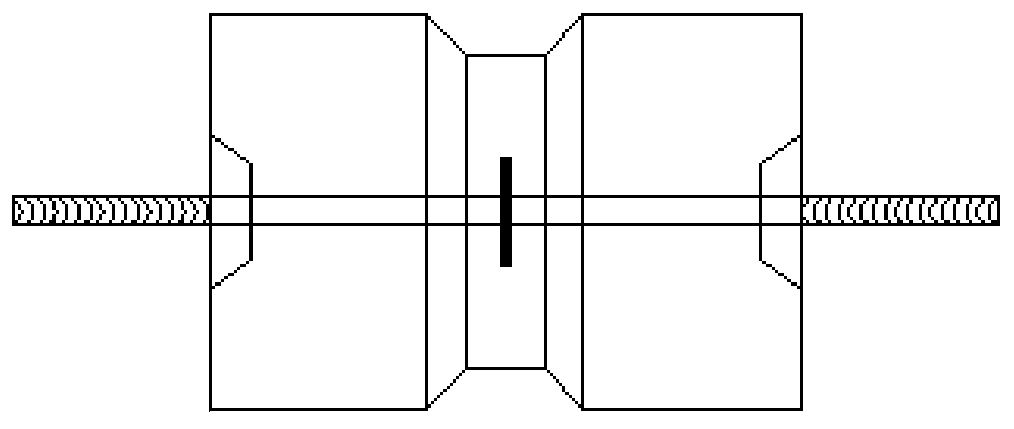

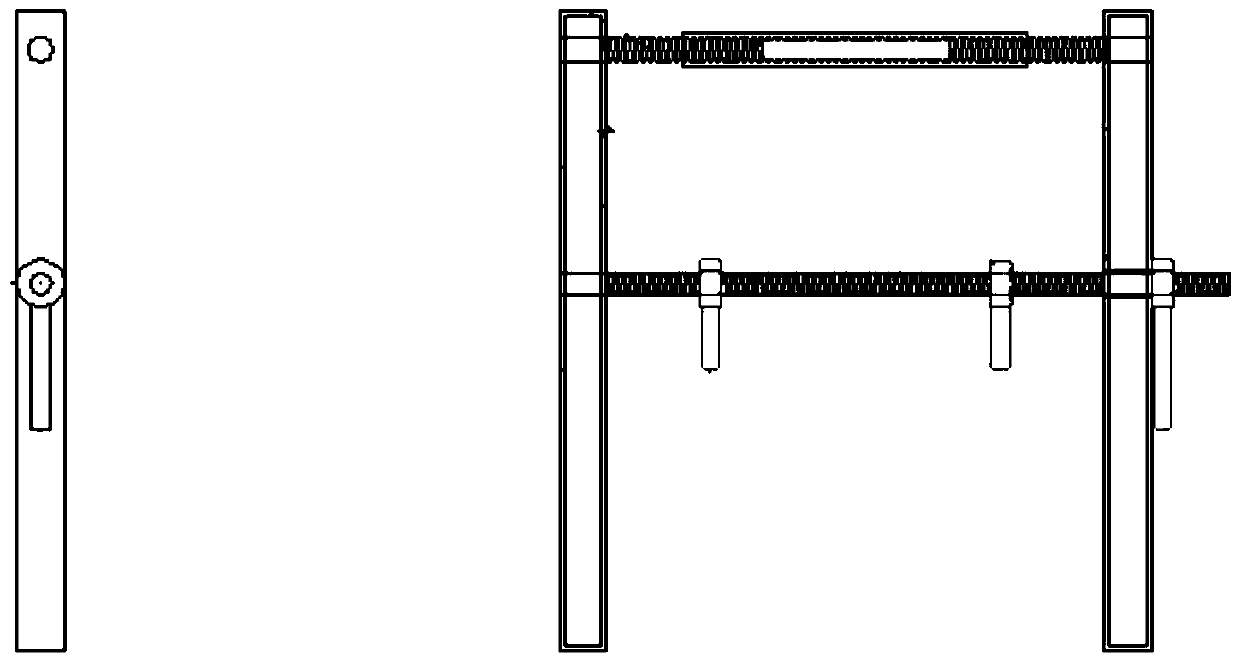

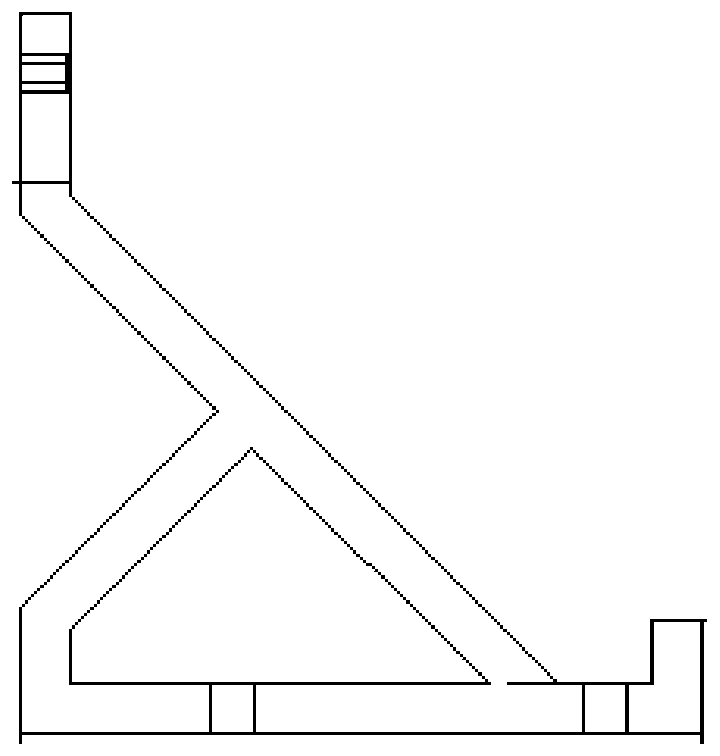

[0029] The hanging formwork system of the present invention mainly includes three parts: a fixed support, a square steel keel, and a limit clamp, and the bottom support of the hanging formwork adopts a water-stop type concrete pad. The side-to-inner back corrugation of the hanging form adopts square steel pipes, which are matched with square steel welded triangular fixed support frames. The outer back flute of the formwork adopts "U" type reinforcement clamps. After the on-site installation is completed, the concrete is poured together with the main structure at one time, which can ensure the integrity of the waterproof guide wall in the kitchen and bathroom.

[0030] The technological process of the present invention is as follows: production of water-stop support pads → U-shaped limit fixture processing and production → adjustable triangular positioning support frame production → configuration of standard templates → positioning and setting-out → installation of water-stop s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com