Side wall single-side formwork supporting system design and optimization method based on BIM technology

A support system and optimization method technology, applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve cumbersome modification, adjustment and optimization, low design efficiency, Design complexity and other issues to achieve the effect of improving design efficiency, saving economic costs, and meeting construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

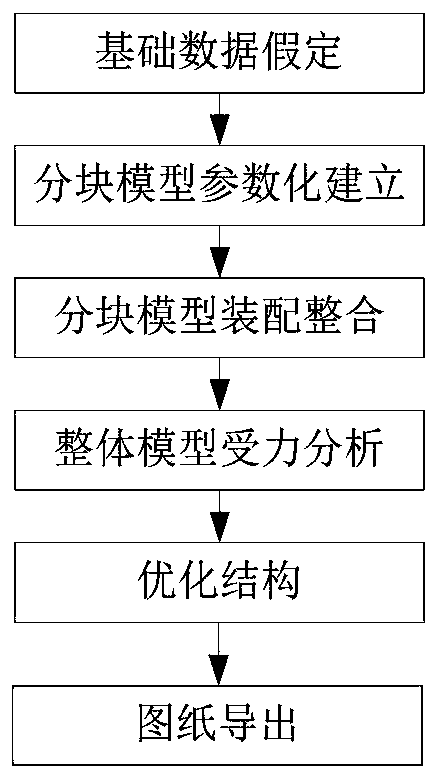

[0033] refer to figure 1 , this embodiment provides a BIM technology-based design and optimization method for the single-side formwork support system of the side wall, and the specific steps are as follows:

[0034] 1) Basic data assumptions

[0035] According to the previous construction experience, the relevant material structure size of the side wall unilateral formwork support system is assumed, mainly including the size and spacing of the sub-keel square timber, the unilateral steel truss bracket size assumption, and the pre-embedded steel bar pull ring size assumption. Among them, the sub-keel square timber is assumed to be 100×100mm, the spacing is 40cm, and it is arranged horizontally; the single-side steel truss support is assumed to be welded by 12# channel steel and 10# angle steel, and the single-side steel truss spacing is 1.0m. The steel bars are processed, assuming that 32 round steel is used, and the layout spacing is assumed to be 50cm.

[0036] 2) Parametri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com