Protection method with sealing structure and sealing protection tool

A sealing structure and tooling technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of environmental pollution, uncontrollable quality of parts coating, high manufacturing cost, and achieve uniform coating quality and cost reduction. Significant synergy and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach ( 1

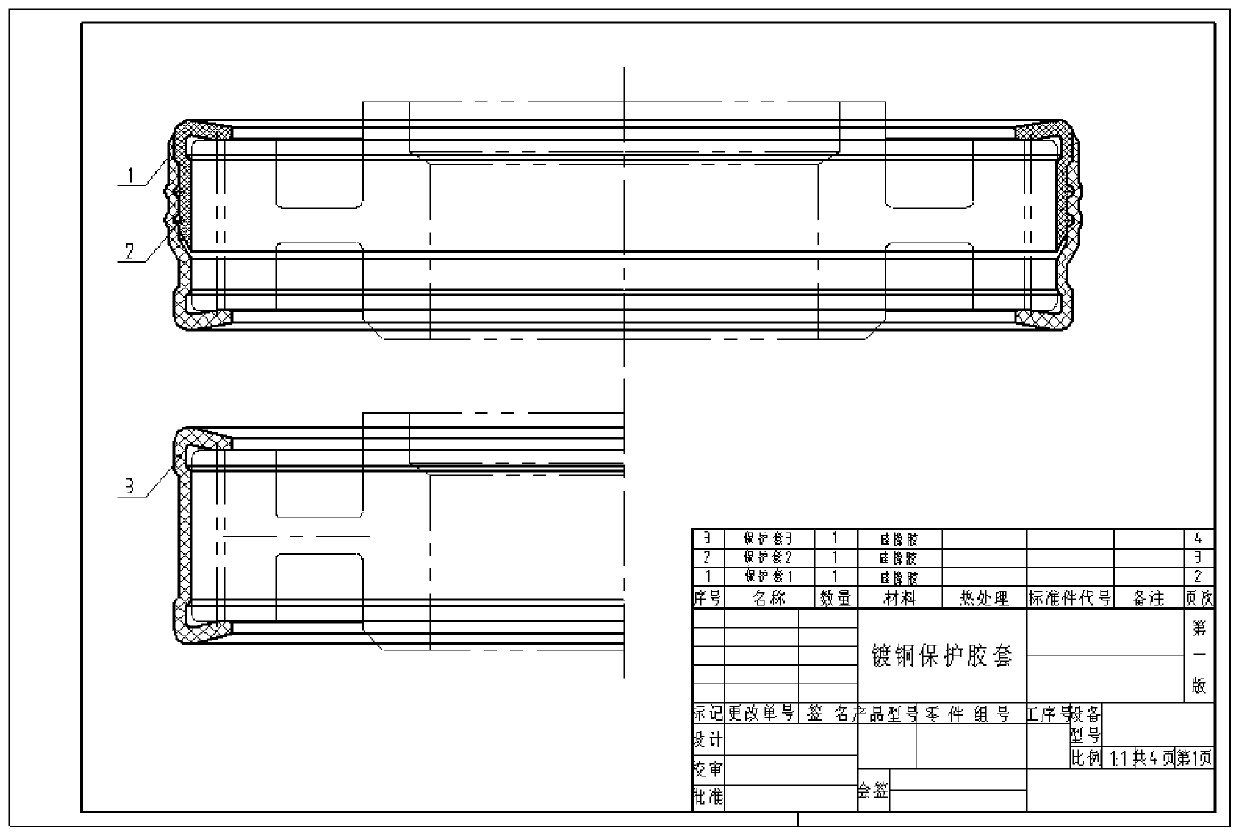

[0040] figure 1 Copper-plated protective tooling for a certain part: the structural design of the sealing protective tooling for the outer diameter end face of the straight tooth.

[0041] The sealing protective tooling is made of silicone rubber;

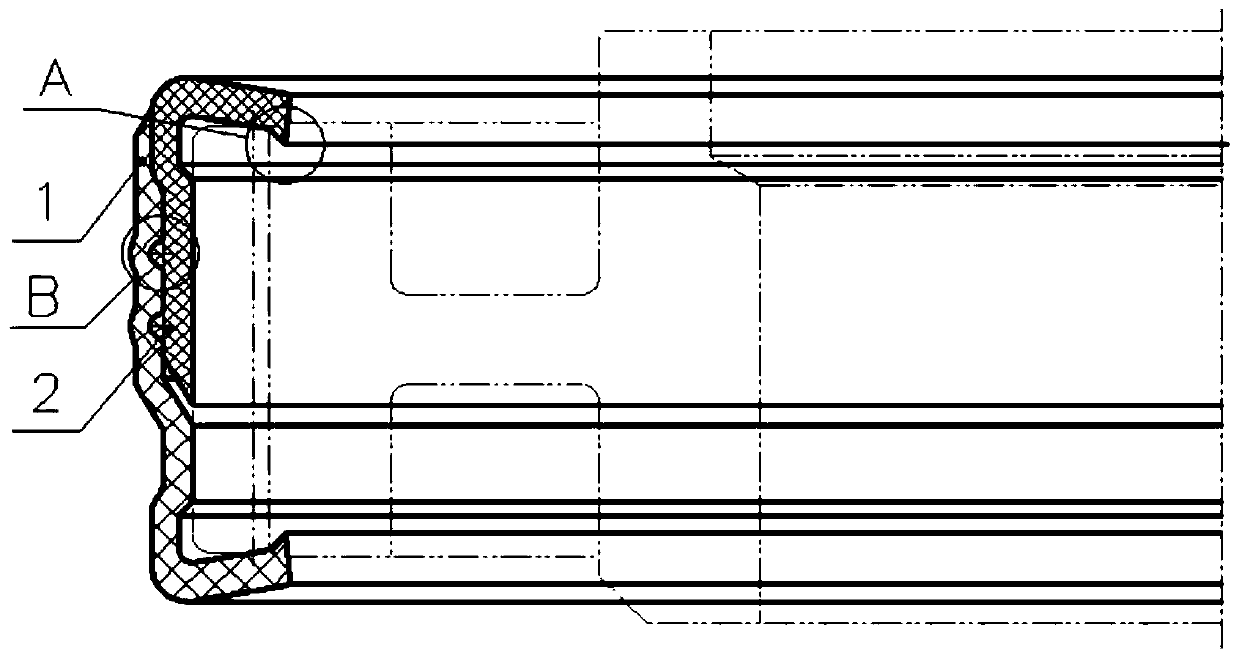

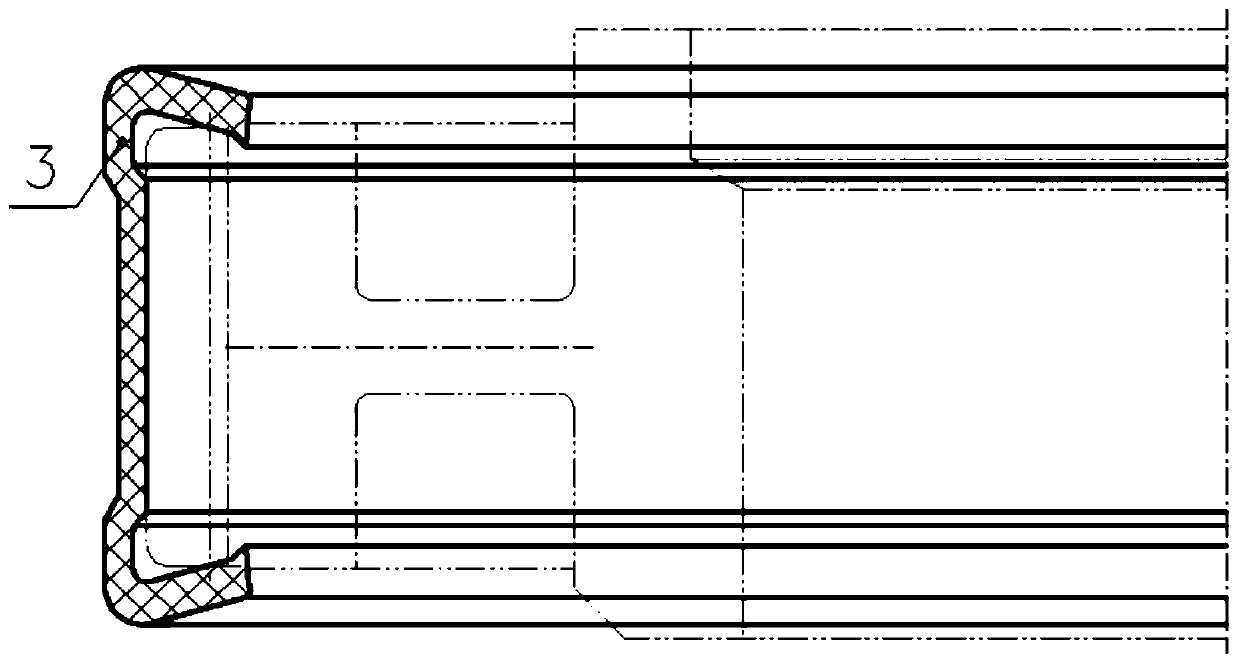

[0042] The sealing protective tooling is divided into split structure ( figure 2 ) and overall structure ( image 3 )design:

[0043] The sealing end of the sealing protective tooling is designed with a sealing lip structure A to increase the sealing effect of the protective sleeve;

[0044] There is sufficient tightness between the protective sleeve and the outer diameter of the protection;

[0045] There is a gap structure at the junction of the tooth top and the tooth side of the rubber protective sleeve, which reduces assembly resistance and increases the sealing effect of the end face.

[0046] For the split structure design, a locking buckle B (anti-skid lock) is designed between the inner and outer jackets.

[0047] A...

Embodiment approach ( 2

[0049] Electroless nickel-plated sealing protective tooling for external force ( Figure 4 ).

[0050] The protective structure includes a silicone rubber sleeve and a pressing plate pressing structure;

[0051] The rubber protective cover is a conformal protective structure ( Figure 5 );

[0052] Two-way compression between the parts through the spacer sleeve ( Image 6 );

[0053]According to the rubber protective structure of the end face of the straight tooth outer diameter, design the corresponding silicone rubber protective sleeve mold. Due to the complex structure of the parts, the selected silicone rubber has a Shore hardness of 40-45°, so that the processed silicone rubber protective sleeve has a good protective effect and is easy to install and disassemble.

[0054] The two ends of the silicone rubber protective sleeve apply external force through the pressure plate;

[0055] The protective part and the pressure applying device are fastened into one body throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com