High-temperature-resistant, low-volatilization, insect-proof, halogen-free and flame-retardant PP material and preparation method thereof

A technology with high temperature resistance and low volatility, applied in the field of functional polymer materials, it can solve the problems of high volatility and high processing temperature, and achieve the effect of facilitating dispersion, improving interface affinity and avoiding direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example relates to a high-temperature-resistant, low-volatility, insect-proof, halogen-free, flame-retardant PP material, which is composed as follows:

[0043] Polypropylene resin 65%,

[0044] Halogen-free flame retardant 25%,

[0045] 10% of high-temperature-resistant and low-volatile insect-proof masterbatch;

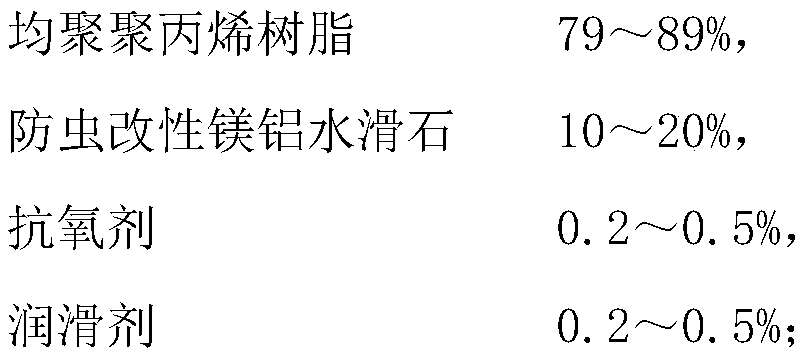

[0046] Among them, the composition of the high-temperature-resistant and low-volatile insect-proof masterbatch is as follows:

[0047]

[0048] The preparation steps are as follows:

[0049] (1) Preparation of insect-resistant modified magnesium aluminum hydrotalcite:

[0050] Heat 500g of magnesium-aluminum hydrotalcite (aluminum-magnesium ratio 1:2) and 10 times its weight of absolute ethanol in a constant temperature water bath at 75°C for 30min, then add 100g of 2-methylbutanol, isobornyl acetate 50g, 50g of D-borneol, stirred at constant temperature for 2 hours, filtered, washed, and dried to obtain insect-resistant modified magnesium aluminu...

Embodiment 2

[0059] This example relates to a high-temperature-resistant, low-volatility, insect-proof, halogen-free, flame-retardant PP material, which is composed as follows:

[0060] Polypropylene resin 60%,

[0061] Halogen-free flame retardant 25%,

[0062] 15% of high-temperature-resistant and low-volatile insect-proof masterbatch;

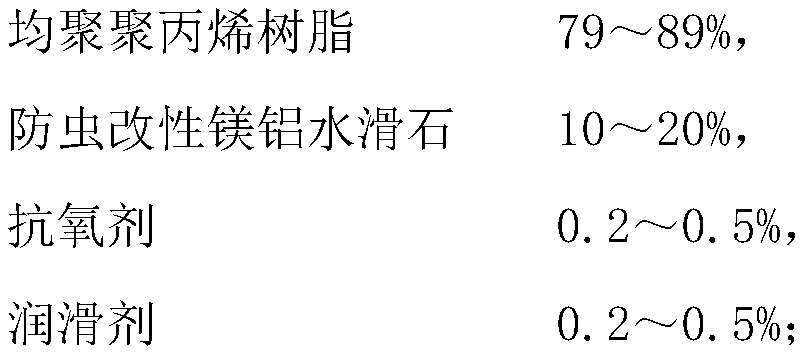

[0063] Among them, the composition of the high-temperature-resistant and low-volatile insect-proof masterbatch is as follows:

[0064]

[0065]

[0066] The preparation steps are as follows:

[0067] (1) Preparation of insect-resistant modified magnesium aluminum hydrotalcite:

[0068] Heat 500g of magnesium-aluminum hydrotalcite (aluminum-magnesium ratio 1:2) and 10 times its weight of absolute ethanol in a constant temperature water bath at 75°C for 30min, then add 100g of 2-methylbutanol, isobornyl acetate 50g, 50g of D-borneol, stirred at constant temperature for 2 hours, filtered, washed, and dried to obtain insect-resistant modified magne...

Embodiment 3

[0077] This example relates to a high-temperature-resistant, low-volatility, insect-proof, halogen-free, flame-retardant PP material, which is composed as follows:

[0078] Polypropylene resin 75%,

[0079] Halogen-free flame retardant 20%,

[0080] 5% of high temperature resistant and low volatile pest control masterbatch;

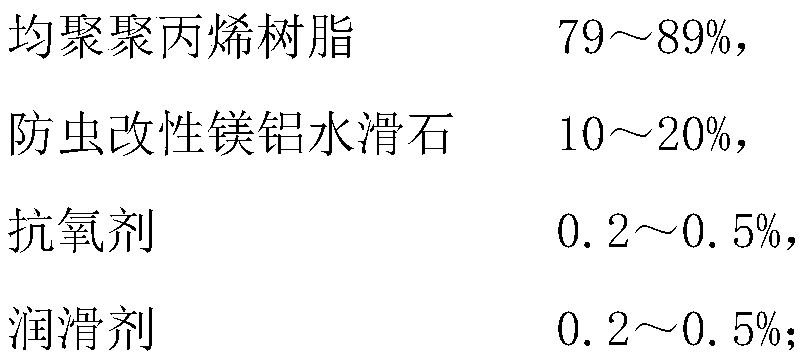

[0081] Among them, the composition of the high-temperature-resistant and low-volatile insect-proof masterbatch is as follows:

[0082]

[0083] The preparation steps are as follows:

[0084] (1) Preparation of insect-resistant modified magnesium aluminum hydrotalcite:

[0085] Heat 500g of magnesium-aluminum hydrotalcite (aluminum-magnesium ratio 1:2) and 10 times its weight of absolute ethanol in a constant temperature water bath at 75°C for 30min, then add 100g of 2-methylbutanol, isobornyl acetate 50g, 50g of D-borneol, stirred at constant temperature for 2 hours, filtered, washed, and dried to obtain insect-resistant modified magnesium aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com