Reactive flame retardant, vinyl smc resin containing the flame retardant

A reactive flame retardant and flame retardant technology, which is applied in the fields of compounds of Group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods to improve flame retardant properties, ensure mechanical properties and flame retardant properties. , the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

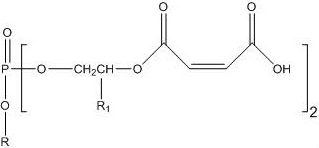

[0043] 10mol monomethyl phosphate (R is -CH 3 ) and 20mol butyl glycidyl ether into the ceramic kettle, stirred at ambient temperature for 0.5h, continued to add 20mol maleic anhydride, raised the temperature to 90°C, stirred for 5h,

[0044] A polycarboxylate flame retardant containing phosphorus and double bonds (R 1 for ) The molecular weight of the flame retardant is 536g / mol, and the phosphorus content is 5.78%.

[0045] The formula of flame retardant vinyl SMC resin is as follows:

[0046] Epoxy vinyl resin (Shanghai Huachang Company, MFE-711) 100 parts by weight

[0047] 20 parts by weight of polycarboxy compound

[0048] 1.5 parts by weight of tert-butyl peroxybenzoate

[0049] Magnesium oxide 3 parts by weight

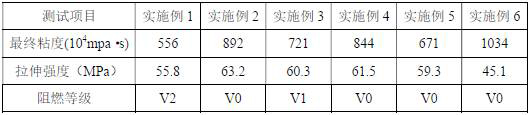

[0050] After the resin preparation is completed, the viscosity of the resin is continuously tested. When the viscosity of the resin remains unchanged, the resin is cured in a high-temperature oven at 130°C, and the mechanical and flame-retardant propert...

Embodiment 2

[0052] 10mol monobutyl phosphate (R is -C 4 h 9 ) and 20mol epichlorohydrin into the ceramic kettle, stirred at ambient temperature for 0.5h, continued to add 20mol maleic anhydride, raised the temperature to 140°C, stirred for 0.5h,

[0053] A polycarboxylate flame retardant containing phosphorus and double bonds (R 1 for ) The molecular weight of the flame retardant is 530g / mol, and the phosphorus content is 5.85%.

[0054] The formula of flame retardant vinyl SMC resin is as follows:

[0055] Polyurethane vinyl resin (Nantong Matech Co., Ureplu-1119): 100 parts by weight

[0056] 80 parts by weight of polycarboxy compound

[0057] 3 parts by weight of dicumyl peroxide

[0058] Calcium hydroxide 1.5 parts by weight

[0059] After the resin preparation is completed, the viscosity of the resin is continuously tested. When the viscosity of the resin remains unchanged, the resin is cured in a high-temperature oven at 130°C, and the mechanical and flame-retardant properti...

Embodiment 3

[0061] 10mol monooctadecyl phosphate (R is -C 18 h 37 ) and 20mol of propenyl glycidyl ether were added to the ceramic kettle, stirred at ambient temperature for 0.5h, continued to add 20mol of maleic anhydride, heated to 120°C, and stirred for 2.5h to obtain a flame-retardant polycarboxy compound containing phosphorus and double bonds agent (R 1 for ) The molecular weight of the flame retardant is 742g / mol, and the phosphorus content is 4.17%.

[0062] The formula of flame retardant vinyl SMC resin is as follows:

[0063] Polyurethane vinyl resin (Nantong Matech Co., Ureplu-1119) 100 parts by weight

[0064] 50 parts by weight of polycarboxy compound

[0065] 2 parts by weight of di-tert-butyl peroxide

[0066] 2.5 parts by weight of magnesium hydroxide

[0067] After the resin preparation is completed, the viscosity of the resin is continuously tested. When the viscosity of the resin remains unchanged, the resin is cured in a high-temperature oven at 130°C, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com