Method for preparing tree whitening agent from solid waste

A technology of solid waste and whitening agent, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve problems such as price increase, endangering staff, polluting the environment, etc., and achieves protection Effects of trees and public safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 A kind of method utilizing solid waste to prepare tree whitening agent, comprises the steps:

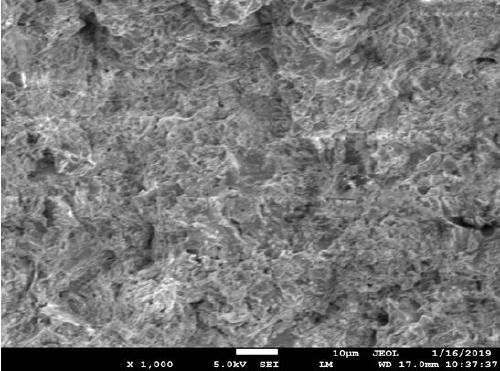

[0023] Step 1: One-pot firing process to prepare composite materials: 7% waste glass powder, 10% desulfurization ash, 80% shell powder, 3% ceramic polishing powder, add water and stir evenly into balls, with a diameter of 1-2cm. Drying, preheating and calcination, the temperature is 850°C, and the temperature is kept for 1.5h. Grinding after cooling, the sieve residue of 0.08mm square hole sieve is less than 1%.

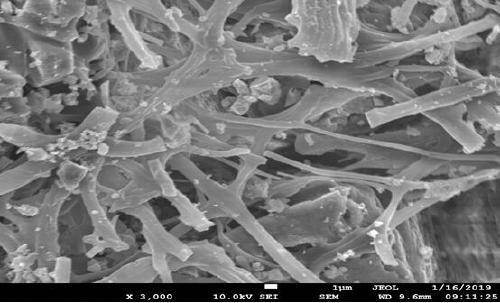

[0024] Step 2: Preparation of goose eggshell-loaded MOFs photocatalytic material: 0.4g of cobalt nitrate and 0.8g of dimethylimidazole were dissolved in 100ml of deionized water, and stirred at room temperature for 8h to obtain a solution. Then add 2g of eggshell powder, 0.4g of nickel nitrate and stir for 1 hour, then centrifuge and dry, the color of goose eggshell changes from white to pink.

[0025] Step 3: Boil the sugar water: Put 1 catties of blo...

Embodiment 2

[0028] Embodiment 2 A kind of method utilizing solid waste to prepare tree whitening agent, comprises the steps:

[0029] Step 1: One-pot firing process to prepare composite materials: 5% waste glass powder, 7% desulfurization ash, 85% shell powder, 3% ceramic polishing powder, add water and stir evenly into balls, with a diameter of 1-2cm. Drying and preheating for calcination, the temperature is 1050°C, and the temperature is kept for 0.5h. Grinding after cooling, the sieve residue of 0.08mm square hole sieve is less than 1%. ;

[0030] Step 2: Preparation of goose eggshell-loaded MOFs photocatalytic material: 0.58g of cobalt nitrate and 0.65g of dimethylimidazole were dissolved in 100ml of deionized water, and stirred at room temperature for 8h to obtain a solution. Then add 3g of eggshell powder, 0.4g of nickel nitrate and stir for 1 hour, then centrifuge and dry, the color of goose eggshell changes from white to pink.

[0031] Step 3: Boil the sugar water: Put 1 cattie...

Embodiment 3

[0034] Embodiment 3 A kind of method utilizing solid waste to prepare tree whitening agent, comprises the steps:

[0035] Step 1: Preparation of shell-based lime powder: put the shells into a high-temperature furnace for calcination at a temperature of 950°C and keep warm for 1.0h. After cooling, it is taken out, sealed, and automatically pulverized to form a lime powder material;

[0036] Step 2: Boil the sugar water: put 1 catties of block sweet potatoes into 1.5L of water and cook, then take out the sweet potatoes.

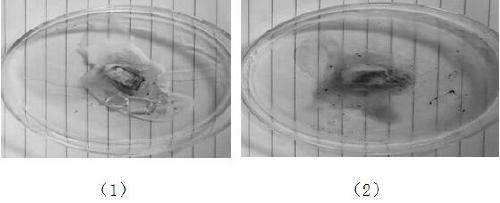

[0037]Step 3: Whitening agent coating: add shell-based lime powder to water and sweet potato syrup, mix and digest for 2 hours to prevent the product from burning trees. Take 1 to 1.2 meters as the brushing height, first paint a circle as the highest whitening line, and then paint from bottom to top, so that it is evenly distributed on the bark surface, and brush to the bottom.

[0038] Features: The preparation process is simple, and it has the functions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com