Novel large dip angle conveyer belt rapping type sweeper and sweeping method

A conveyor belt and large inclination technology, which is applied in the field of new type large inclination conveyor belt vibrating cleaners and cleaning, can solve the problems of substandard environmental protection, large amount of returning powder, and too much dust returning to the city on the large inclination conveyor belt. Achieve significant social and environmental benefits and the effect of reducing dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

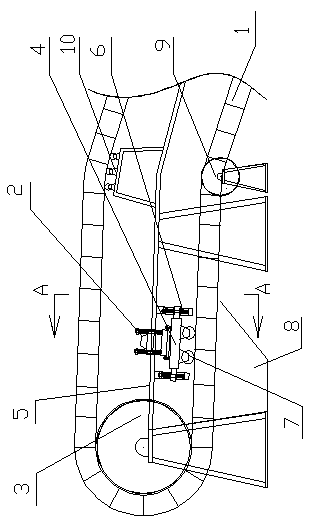

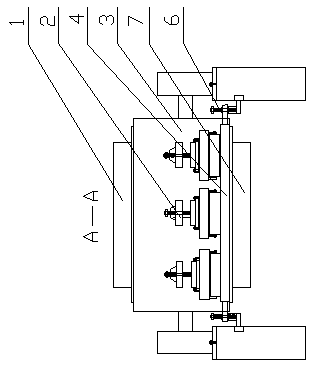

[0015] A new type of rapping cleaner for a large-inclination conveyor belt, which consists of: a large-inclination conveyor belt 1, an electromagnetic vibrator 2, and a driving drum 3, and a rapper body 4 is installed on the return belt of the driving drum. Described rapper body is connected on the conveyor belt frame 5 by 4 leading screws, and described leading screw is connected with described rapper body by 8 rapper damping springs 6, and described vibrator The bottom of the beater body is equipped with a rapping idler roller 7, and the top of the described rapper body is equipped with 3 electromagnetic vibrators described above, and the bottom of the described rapper body is equipped with a coal receiving hopper 8, so The coal receiving hopper described above is used to collect the pulverized coal rapped by the rapper body.

Embodiment 2

[0017] According to the novel large-inclination-angle conveyor belt rapping cleaner described in Embodiment 1, the drive drum and the return roller 9 are sleeved with the high-inclination-angle conveyor belt, and the frame is equipped with idlers 10. The idler roller supports the conveying at a large inclination angle.

Embodiment 3

[0019] According to the novel rapping cleaner for a conveyor belt with a large inclination angle described in Embodiment 1 or 2, the conveyor belt with a large inclination angle is a corrugated edge conveyor belt with a large inclination angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com